I&O manual

8

Antifrost protection

WIRING

IMPORTANT!

CAUTION

See product nameplate wiring.

Check that the voltage and the frequency of the electrical supply

When the unit is out of service, remember to arrange in good

time for the entire water content in the circuit to be drained

down.

IMPORTANT!

Mixing the water with glycol modifies the performance of the

unit.

Pay attention to the safety instructions regarding ethylene

glycol which are printed on the container.

If the unit is not used during the winter period, the water contained in

the system may freeze.

Draining the water circuit needs to be undertaken in good time.

However, if the operation of draining the system is felt to be too

laborious, a suitable quantity of antifreeze may be mixed with the

water instead.

3.2.2 Electrical connections

CAUTION

correspond to 220-240V single phase at 50Hz; that the available

power is sufficient for the running the equipment; and that the

supply cables are of adequate section for the maximum current

which will be required.

Make sure that the electrical supply system complies with

current national safety regulations.

Electrical connections must be made in accordance with the

wiring diagrams supplied with the machine. For connection to the

electrical supply network, use double-insulated flexible cable,

twin pole + earth, section 1.5mm

2

type H05RN-F.

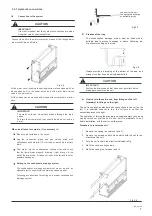

Pass the supply cable through the slot beside the air filter. Use

the cable clamp provided on the inner side of the panel to

secure the supply cable and the connecting cables, and strip

only the length of cable needed to go into the connector block.

If the unit is mounted on a metal surface, earth connections

must be made in compliance with local regulations. If the

optional extra electric heating element is fitted, a separate

power supply must be provided. Use double- insulated flexible

cable, twin pole + earth, section 2.5mm

2

, type H05RN-F.

IMPORTANT!

Electrical connection of the unit must be carried out by

qualified personnel in compliance with the regulations in

effect in the country where the unit is installed. The company

shall not be held liable for damage to persons or property

caused by incorrect electrical connection.

The power cord type designation is H05RN-R or

above/H07RN-F.

This appliance can be children aged from 8 years and above

and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have

been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without

supervision.

The appliance shall be installed in accordance with national

wiring regulations.

DANGER!

Always install a general automatic switch in a protected area

near the appliance with an adequate capacity characteristic

delayed curve with sufficient breaking power. There should be

a minimum distance of 3mm between the contacts. Earth

connection is compulsory by law to ensure user safety while

the machine is in use.

3.2.3 Startup instructions

CAUTION

IMPORTANT!

Machine commissioning or the first start up must be carried

out by skilled personnel qualified to work on this type of

product.

DANGER!

Before starting up, make sure that the installation and

electrical connections have been carried out in accordance

with the instructions in this manual. Also make sure that there

are no unauthorized persons in the vicinity of the machine

during these operations.

Pipeline system has been vacuumed before initial start the

equipment

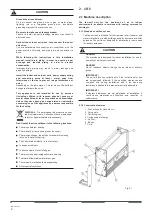

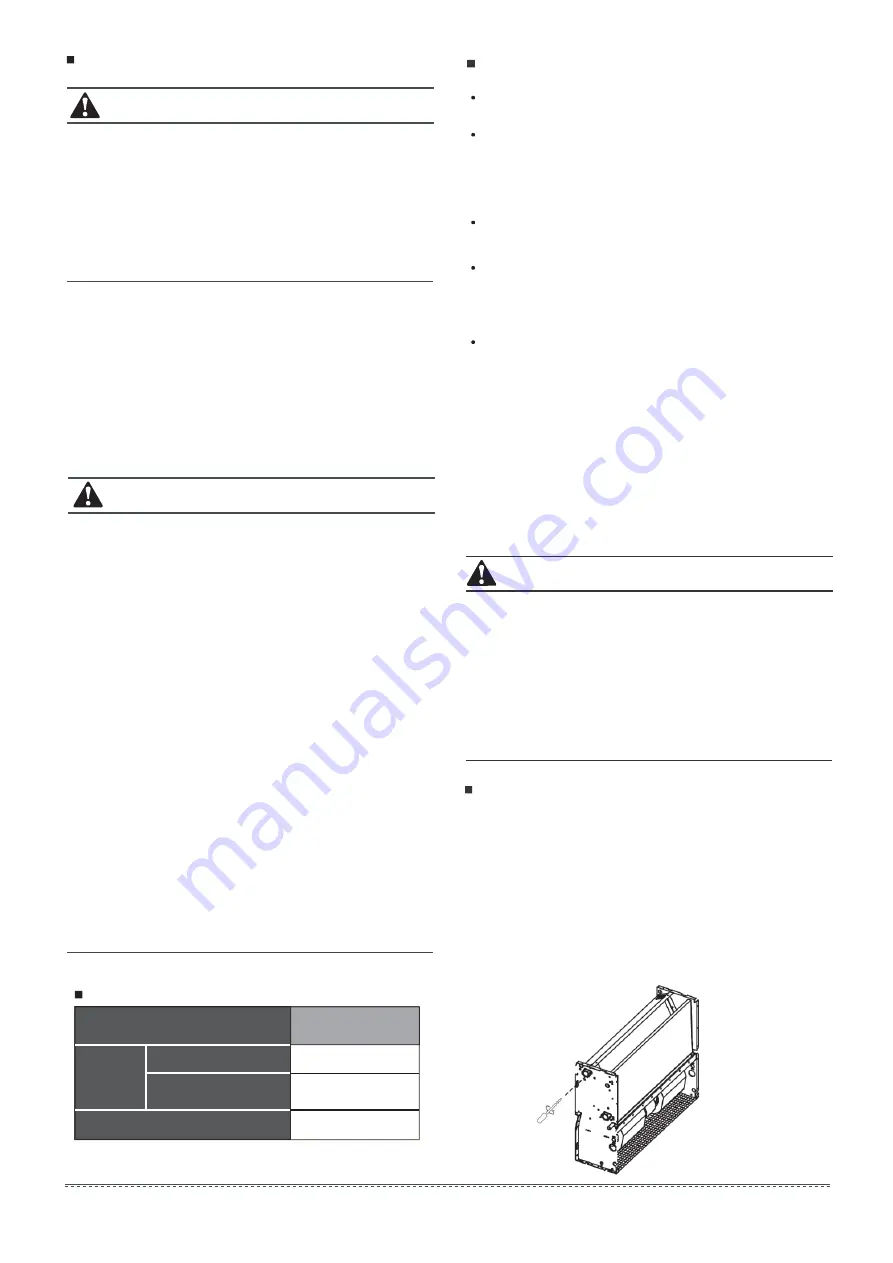

1 Remove the connecting pipe’s side cover panel by cross

screwdriver.

2 Remove the bolts that showed at the figure by slotted screw

driver. Start up the pump to circulate the pipeline water and

vacuum air from the system until there have water flow out

from bolt holes, and then tighten the bolts the system.

3 Shutdown the system that showed at the figure by slotted

screwed and replace the side cover panel.

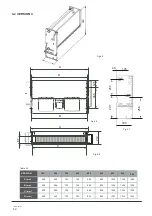

Table 3-2

AIR FLOW(m

3

/h)

255~1530

POWER

PHASE

FREQUENCY AND VOLT

1-phase

220-240V~ 50Hz

CIRCUIT BREAKER/FUSE(A)

15/15

Fig.3-10

Summary of Contents for KFC-S-2T-250D

Page 2: ......

Page 16: ...MD15IU 015CW DZ1 16126200A06812 ...

Page 17: ...I O manual 15 ...

Page 18: ......

Page 19: ...I O manual 17 ...

Page 20: ......