I&O manual

9

Preliminary checks before startup

Check for the presence of air in the water system.

Before starting up the unit, make sure that:

the unit is positioned correctly;

the flow and return pipes of the water system are correctly

connected;

the pipes are clean and free of air;

the unit falls correctly towards the drainage outlet and the

trap;

the heat-exchangers are clean;

the electrical connections are correct;

the screws holding the cables are well tightened;

the supply voltage is as required;

the power consumption of the blower is correct and does not

exceed the maximum permitted.

3.2.4 Maintenance

1

remove the casing of the machine (on units I and II );

2

start the system and run for a few minutes;

3

stop the system;

4

slacken the bleed screw on the inlet manifold and

bleed the air.

5

Repeat the operation several times until no more air

comes out of the system.

At the end of the season

Drain the water system (for all heat exchangers).

To avoid the risk of rupture due to freezing, it is

advisable to drain the water from the system at the

end of every season.

Electrical Circuit

The following operations are recommended for the

maintenance of the electrical circuit:

DANGER!

CAUTION

1

check the unit 's power absorption using a clip-on

ammeter and compare the reading with the values

shown on the documentation;

Maintenance work must only be carried out by qualified

technicians authorized to work on air-conditioning and

refrigeration systems. Use suitable work gloves.

Do not introduce pointed objects through the air intake grilles.

Disconnect the power supply before cleaning and maintenance.

Use dry cloth to clean the unit.

Always disconnect the unit from the mains power supply at

the main isolator switch before carrying out maintenance

work or checks. Make sure that no one accidentally supplies

power to the machine, lock the main switch in the Off

position.

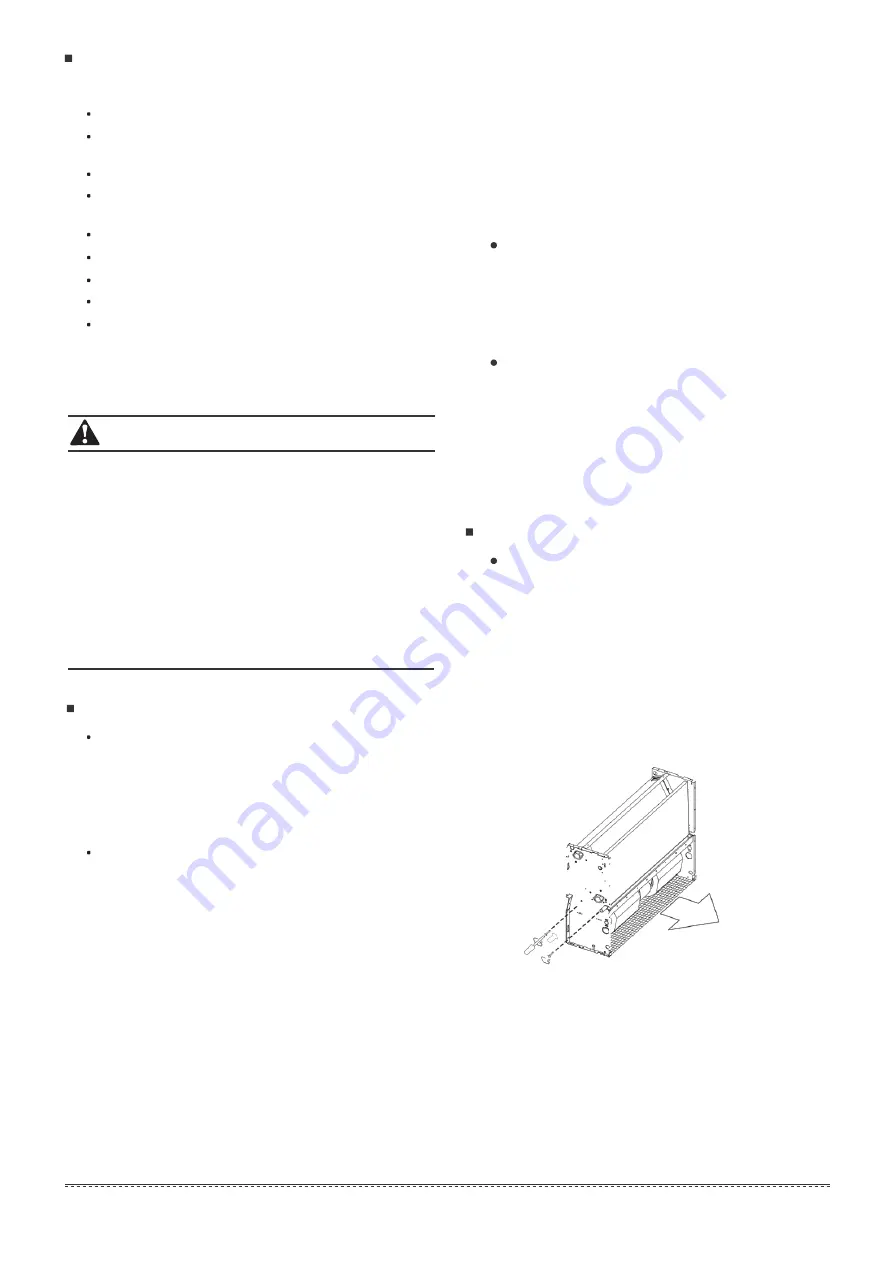

SCHEDULED MAINTENANCE

Once a month

Check the state of cleanliness of the air filters.

The air filters are made of fiber and are washable in

water. The state of cleanliness of the filters must be

checked regularly at the start of the operating season and

monthly.

Every six months

Check the state of cleanliness of the heat-exchanger and

the condensation drain-tube. With the unit switched off,

remove the casing of the machine and check the state of

the heat-exchanger and the condensation drain-tube. If

necessary:

2

inspect and, if necessary, tighten the electrical

contacts and terminals.

NON-SCHEDULED MAINTENANCE

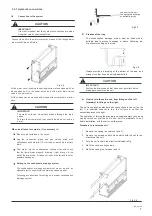

Replacement of the blower assembly

In the case of burnout of the blower electric

motor, it is necessary to replace the entire blower

assembly.

Procedure for removal of the blower:

1

Remove the casing (on units I and II)

2

Disconnect the electrical supply cable from the

blower;

3

Remove the screws on both sides which hold the

blower to the structure of the unit;

4

Take out the blower.

1

remove any foreign bodies from the finned surface

which may obstruct air flow;

2

clean off the dust with a jet of compressed air;

wash and brush, gently, with water;

3

dry with a jet of compressed air;

4

check that there are no obstructions in the

condensation drain tube which could prevent the

normal flow of water.

Fig.3-11

5

Procedure for refitting the blower is a reversal of the

above.

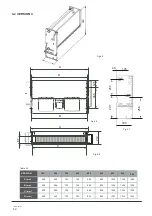

Summary of Contents for KFC-S-2T-250D

Page 2: ......

Page 16: ...MD15IU 015CW DZ1 16126200A06812 ...

Page 17: ...I O manual 15 ...

Page 18: ......

Page 19: ...I O manual 17 ...

Page 20: ......