10

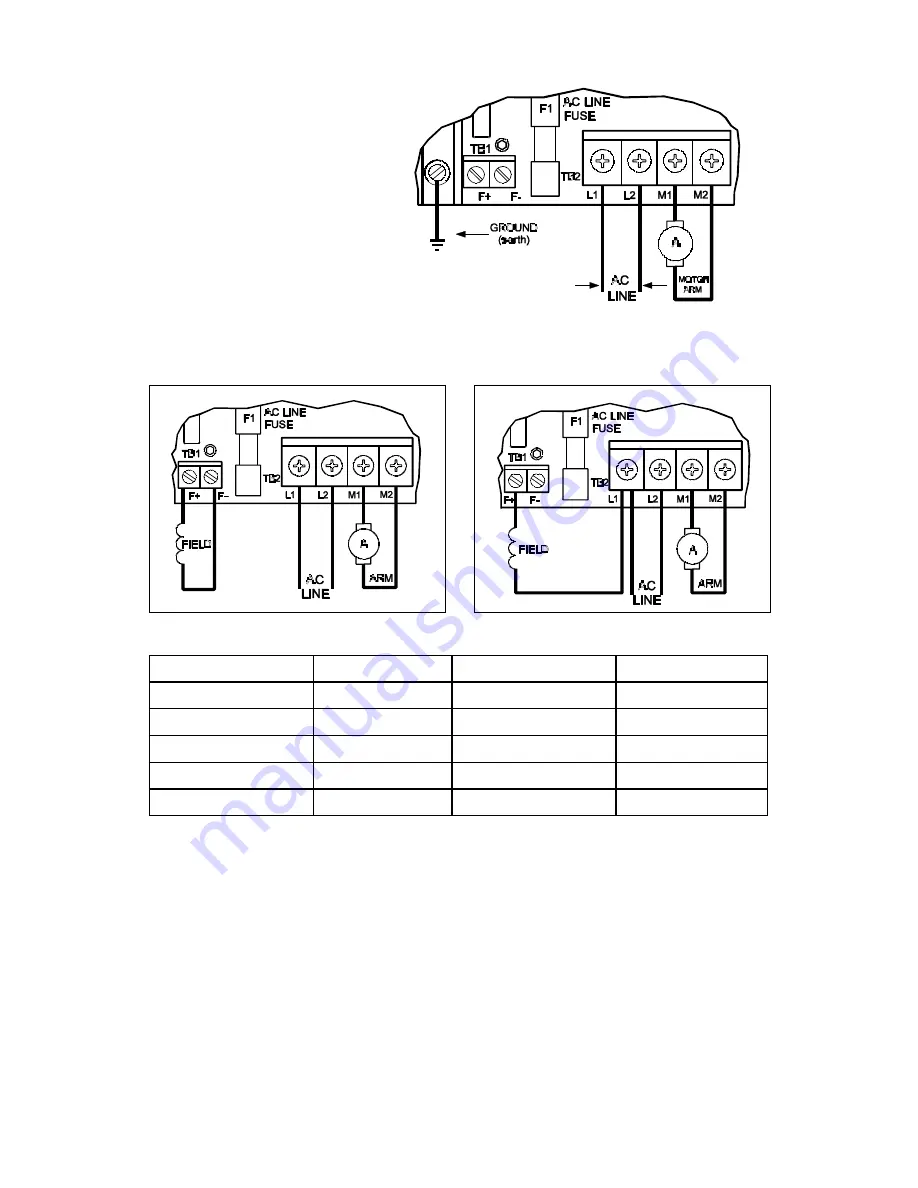

FIG. 6 – AC LINE AND ARMATURE CONNECTION

C. Field

(For Shunt Wound

motors

only

) – Do not

use F+ and F- terminals for any

other motor type. Connect

motor shunt field to terminals

F+ and F- for 90VDC motors

with 100VDC fields and

180VDC motors with 200VDC

fields. For motors with half

voltage fields, 90VDC motors

with 50VDC fields and 180VDC

motors with 100 VDC fields,

connect field to terminals F+ and L1. See table 7 for

summary of Field Connections.

CAUTION – Shunt-Wound motors may be damaged if field remains connected

without motor rotating for an extended period of time.

FIG. 7A – FULL VOLTAGE FIELD

FIG 7B – HALF VOLTAGE FIELD

TABLE 7 – FIELD CONNECTIONS (Shunt Wound Motors Only)

AC Line Voltage (VAC)

Motor Voltage

Field Voltage (VDC)

Field Connection

115

90

100

F+, F-

115

90

50

F+, L1

230

180

200

F+, F-

230

180

100

F+, L1

230

90*

100

F+, L1

*Step down operation (see sec. III C, p. 6).

D. Ground

– Be sure to ground (earth) the control via green screw located on chassis.

E. Main Speed Potentiometer

– The main speed potentiometer can be connected in several

ways using terminals "10," "11," "12," "13." ( A 5K ohm potentiometer is supplied with

control. A 10K potentiometer can also be used.)

[WARNING! Terminals “10,” “11,”

“12" and “13" are not isolated from AC line. Do not ground (earth).]

i.

Unidirectional operation only – Connect potentiometer to terminals "10," "12," "13" for

forward direction. (To operate in reverse direction, connect to "11," "12," "13.")

ii.

Bidirectional operation using reversing contacts – Connect to terminals "10," "11,"

"12," "13" as per fig. 8, p. 11.

iii. Bidirectional operation with potentiometer – Connect potentiometer to terminals "10,"

"11," "12" as per fig. 8, p. 11.