OPERATING THE MACHINE

5-2

NOTE:

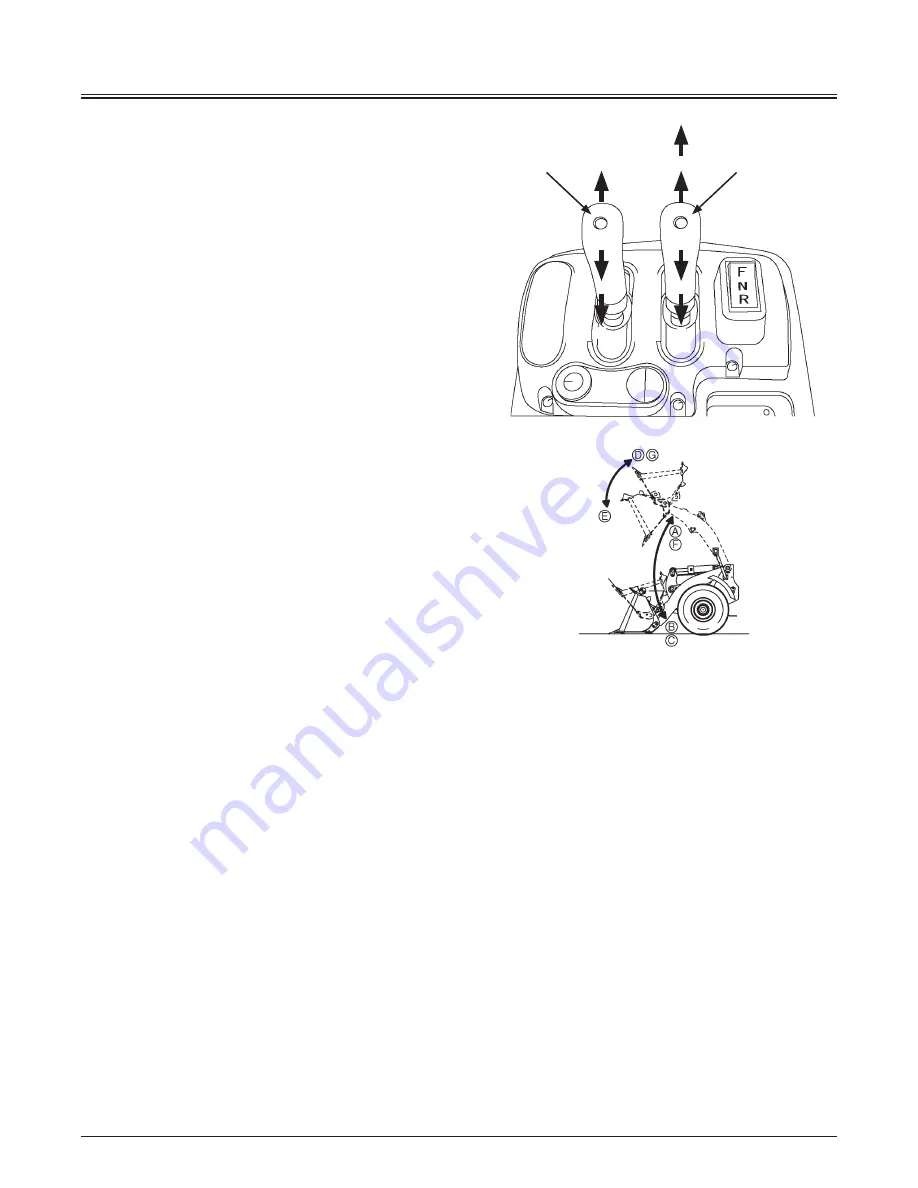

1.

When applying lift arm control lever (1) in the "Raise"

position (A), the lever is moved (F) until the lift arm reaches

the position preset by the lift arm kickout. When the lift

arm moves the preset position, lift arm control lever (1)

automatically moves to the Neutral (N) position.

2.

When applying bucket control lever (2) in the "Tilt"

position (D) after bucket dump operation, the lever is moved

(G) until the bucket reaches the position preset by the bucket

auto leveler. When the bucket reaches the preset position,

bucket control lever (2) automatically moves to the Neutral

(N) position.

3.

When pushing down lift arm control lever (1) to the

"Float" position (C), the lift arm moves to the position preset

by lift arm auto-leveler system and is held in that position.

When the lift arm moves to the preset position, lift arm control

lever (1) automatically moves to the "Neutral" (N) position.

(Machine is equipped with the lift arm auto-leveler system)

NOTE: When operating the machine in Float (C) position,

first hold the lift arm at the float position; then further tilt

the lever to the Float position, and lower the lift arm on the

ground.

M4GB-01-073

2

1

MNEC-03-003

C

B

E

N

N

A

F

G

D

Summary of Contents for 70Z7

Page 2: ...93108 00691 April 2015...

Page 5: ......

Page 11: ...MACHINE NUMBERS 2 MEMO...

Page 51: ...SAFETY LABELS S 40 6 10 4 1 3 9 6 5 SS 3461...

Page 171: ...OPERATOR S STATION 1 110 MEMO...

Page 173: ...BREAK IN 2 2 MEMO...

Page 187: ...OPERATING THE ENGINE 3 14 MEMO...

Page 231: ...OPERATING THE MACHINE 5 24 MEMO...

Page 359: ...MAINTENANCE 7 118 MEMO...

Page 363: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 4 MEMO...

Page 367: ...STORAGE 10 4 MEMO...