MAINTENANCE

7-49

1

2

3

3

4

5

6

4

5

6

7

1

2

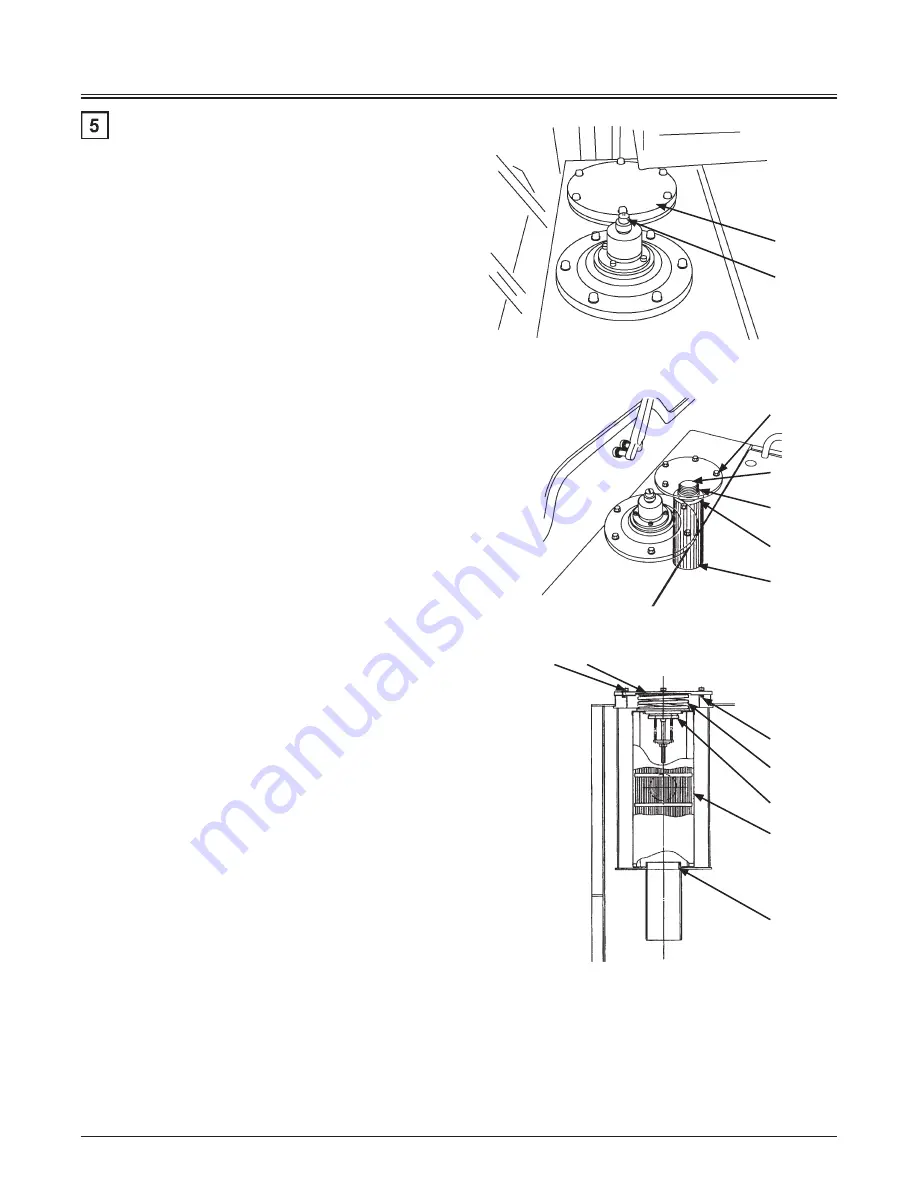

Replace Hydraulic Tank Oil Filter

--- every 1000 hours

WARNING: Hydraulic oil becomes hot during

operation. Severe burns may result if skin comes in

contact with hot hydraulic oil. Wait for the oil to cool

before starting any maintenance work.

Especially when removing the filter, be careful that the

remaining oil in the filter does not spill.

Replacement Procedures

1. Park the machine following the same procedures as

described on page 7-7 for preparation of inspection/

maintenance work.

2. Install articulation lock bar to the front and rear of the

chassis by following the procedures described on page

7-9.

3. Clean the vicinity around cover plate (1).

4. Get a container and workshop towels to hold the spilled

oil and the element. Relieve the air pressure from the

hydraulic oil tank by pressing air bleed valve (8).

5. Loosen bolts (2) (6 used) to remove cover (1) and O-ring

(3). When removing cover (1), slowly remove the cover

while pressing the cover downward so that spring (4)

does not fly off. Slowly permit cover to rise, then carefully

remove.

6. Remove spring (4), valve (5) and element (6).

7. Replace element (6) and O-ring (3) with new ones. Install

new element and new O-ring in the hydraulic oil tank.

Before installing element (6), make sure that rubber (7) is

present.

8. Install cover (1) with bolts (2) (6 used).

Tightening torque: 49.9 N·m (5.1 kgf·m, 37 lbf·ft)

8

M4GB-07-044

M4GB-07-051

M4GB-07-052

Summary of Contents for 70Z7

Page 2: ...93108 00691 April 2015...

Page 5: ......

Page 11: ...MACHINE NUMBERS 2 MEMO...

Page 51: ...SAFETY LABELS S 40 6 10 4 1 3 9 6 5 SS 3461...

Page 171: ...OPERATOR S STATION 1 110 MEMO...

Page 173: ...BREAK IN 2 2 MEMO...

Page 187: ...OPERATING THE ENGINE 3 14 MEMO...

Page 231: ...OPERATING THE MACHINE 5 24 MEMO...

Page 359: ...MAINTENANCE 7 118 MEMO...

Page 363: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 4 MEMO...

Page 367: ...STORAGE 10 4 MEMO...