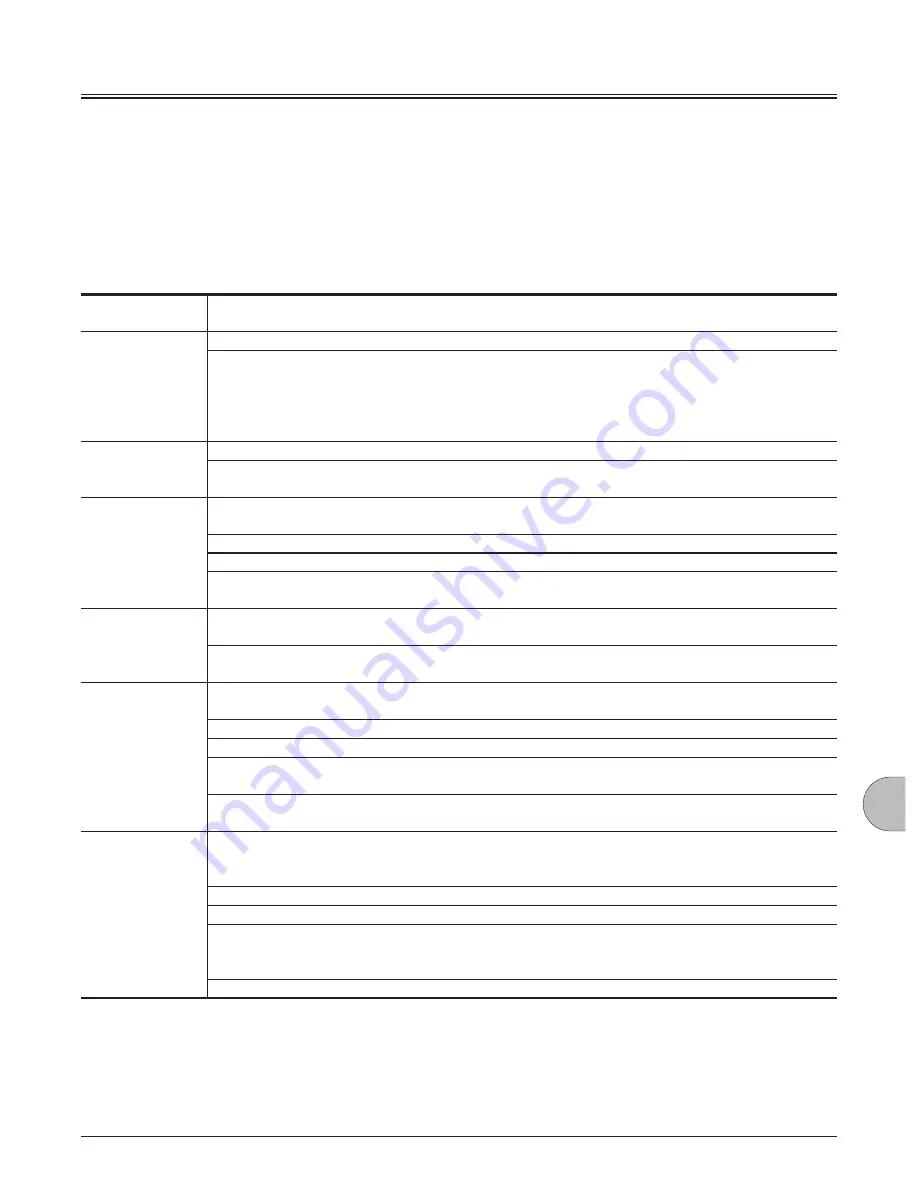

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

9-1

Operating

Conditions

Precautions for Maintenance

Muddy Soil, Rainy

or Snowy Weather

Before Operation: : Check tightness of plugs and all drain cocks.

After Operation

: Clean the machine and check for cracks and damage. Check for loose or

missing bolts and nuts. Lubricate all necessary parts.

If the machine should be submerged in water more than approximately 450

mm (17.7 in) water may get into the brake device (like the park brake), resulting

in poor braking performance. Watch out when starting/stopping the machine.

Near the Ocean

(or near chemical

treatment place)

Before Operation: : Check tightness of plug and all drain cocks.

After Operation

: Thoroughly clean the machine with fresh water to wash off salt.

Service electrical equipment often to prevent corrosion.

Dusty Atmosphere Air Cleaner

: Clean the element regularly at shorter service intervals when indicator

illuminates.

Radiator

: Clean the oil cooler and the radiator cores.

Fuel System

: Clean the filter element and strainer regularly at shorter service intervals.

Electrical

Equipment

: Clean them regularly, in particular, the commutator surface of the alternator

and starter.

Rocky Ground

Chassis

: Check for damage on tires, for loose, cracked, worn, and damaged bolts and

nuts.

Front

Attachment:

: Standard attachment may be damaged when digging rocky ground. Use a

heavy duty bucket. Consult your nearest Kawasaki dealer.

Freezing Weather

Fuel

: Use high quality fuel suitable for low temperature.

Check the fuel tank breather pipe freezing.

Lubricant

: Use high quality low viscosity hydraulic oil and engine oil.

Engine Coolant

: Be sure to use antifreeze.

Battery

: Fully charge the batteries regularly at shorter service intervals. If not charged

fully, electrolyte may freeze.

Tires and Frames : Keep tires and frames clean. Park the machine on a hard surface to prevent the

tires from freezing to the ground.

When handling

old paper and/or

industrial waste

Engine

compartment

: Remove old paper and/or waste accumulated around the radiator and in the

engine compartment, possibly causing overheating or fires of the machine if

not removed.

Air cleaner

: Clean the element at shorter intervals.

Fuel system

: Clean and replace the elements and the filters at shorter intervals.

Loader frame

: Remove the accumulated paper and/or waste from the surroundings around

the loader frame and the attachment. Failure to do so may cause damage of the

machine.

Radiator

: Wash as frequently as possible to prevent corrosion due to chemical materials.

IMPORTANT: If material to be handled is a substance that causes corrosion such as salt or chemical, consult your

nearest Kawasaki dealer. Special modification or treatment may be needed for the machine. If the machine

continues to be used, malfunction may occur due to corrosion.

Consult your nearest Kawasaki dealer when the machine is operated under special condition (s).

Maintenance Under Special Environmental

Conditions

WARNING:

y

Before operating the machine in a river, check the

riverbed conditions in advance.

y

Avoid driving the machine into a river where the

riverbed is steep and deep or the stream is rapid.

Summary of Contents for 70Z7

Page 2: ...93108 00691 April 2015...

Page 5: ......

Page 11: ...MACHINE NUMBERS 2 MEMO...

Page 51: ...SAFETY LABELS S 40 6 10 4 1 3 9 6 5 SS 3461...

Page 171: ...OPERATOR S STATION 1 110 MEMO...

Page 173: ...BREAK IN 2 2 MEMO...

Page 187: ...OPERATING THE ENGINE 3 14 MEMO...

Page 231: ...OPERATING THE MACHINE 5 24 MEMO...

Page 359: ...MAINTENANCE 7 118 MEMO...

Page 363: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 4 MEMO...

Page 367: ...STORAGE 10 4 MEMO...