Check out and Calibration:

C

lean the board of any flux residue. This will help in inspecting all the solder connections. “Electrical Parts Cleaner”,

available at most commercial electrical parts suppliers works well to remove flux. Denatured alcohol will also work. Avoid

rubbing alcohol, as this leaves a white residue. Using your magnifier, inspect all the solder connections, looking in

particular for any you might have missed making. Hopefully, you have all the ICs installed with the proper orientation and

location, as this type of error is not easy to correct. Same goes with the caps, as it’s now difficult to verify their correct

values.

●

If you have already installed L14, remove it before doing the initial power up tests.

•

Use an ohm meter to check for shorts across the DC in, +3.5 and +5 regulator outputs to ground.

•

Find and eliminate short if one is detected.

•

Wire up a 9V supply to the power plug (Use 9V battery or current limited supply set to 50 ma limiting) to start. This

way, if there is a problem, its unlikely any damage will result from too much current being drawn.

•

Plug a set of stereo headphones into the headphone jack.

•

Plug in the power supply

•

You should hear the power up message “4” or “2” in the headphones and see a that number appear on the LED display.

If you hear this message, you know the processor and audio amp are working fine.

•

Check the voltage at TP1, it should be 0 volts. If not, check connections on R19.

•

Check the voltage on the PA gates, Q7 to Q9. This voltage should be zero (0) volts. If it is not, check solder

connections on U8 pins.

•

Plug a paddle into the paddle jack and send some dits and dahs. You should of course, hear them in the headphones.

•

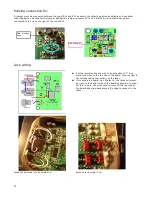

Connect a voltmeter between ground and the Drain of Q5, the PA keying transistor. (Large metal tab is Drain).

•

Send a string of Dahs and watch the voltmeter. The voltage reading should go to near the DC supply input voltage. It

should then slowly decay to zero when you stop sending. This is the voltmeter discharging the .1 uF bypass cap. Check

the soldering in the keying circuit if there is a problem.

•

Remove power from the board.

•

You can now install L14.

Reference Oscillator Frequency Calibration:

NOTE: Entering the calibration mode will rest the reference, offset and initial power on frequencies to their default values.

This is done to ensure “known good values” are used in the off chance the stored values become corrupted.

The “ideal” reference frequency of 40.000,000 MHz is initially assumed to calculate the DDS VFO frequency. In practice,

the reference oscillator has a +/- 100 ppm tolerance. This tolerance can cause an error between what the processor thinks

the operating frequency is and what it really is. The error would be most noticeable on the higher bands, where the

reference clock is less divided. Therefore, this calibration is provided to adjust the value of the reference frequency value

used in the DDS frequency calculation to exactly match the actual oscillator frequency and therefore produce the expected

operating frequency.

However, the typical error is small enough that if you don't have an accurate frequency counter, it is usually best to use the

default values and “click past” this part of the calibration.

This calibration is most easily done with an accurate frequency counter. If you do not have access to one, but do have a rig

with general coverage, good calibration and can tune to 10 MHz, then you can use that. If you can connect up a PSK

program or other audio spectrum analyzer software which can show you the audio frequency of the signal from the rig's

audio, this will help a lot. Set the rig to receive USB at 9.999,000 MHz. This will cause a 1 kHz beat note when a

10.000,000 MHz signal is received. The PSK waterfall can be used to show you when you have adjusted the DDS frequency

to produce the exact 1 kHz beat note. A short pick up wire attached to a piece of coax going to the rigs antenna jack and

placed near the TP1 test point should pick up plenty of signal. If you have no means of accurately measuring 10 MHz, skip

through this procedure by clicking the

MENU

switch after step 6 and go directly to the LO cal procedure.

1. Click and hold closed both the

RIT

and

Tune UP

switches.

2. Apply power.

3. “CR” will be annunciated by the side tone. “C” and then “r” will appear on the LED display when calibration mode is

enabled.

4. Release the switches.

5. Connect a frequency counter to DDS TP1.

6. Wait a minute or two for the oscillator to stabilize.

7. Using the tune up and tune down switches, adjust the frequency at TP1 to exactly 10.000,000 MHz.

8. Once the frequency is adjusted, click the MENU switch to store the new reference frequency.

9. The side tone will now announce “CO” A low pitched tone will be heard in the headphones. The display will change to

“o”

NOTE: if you don't get any output from the DDS, often times this is due to a bad or missing solder connection to one of the

12

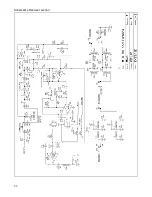

Summary of Contents for Mountain Topper

Page 22: ...Schematics Receiver section 22 ...

Page 23: ...CPU TRANSMITTER Sections 23 ...