GB - 19

4.2.5

Hints for EMC Conform Wiring

• Install the cabinet or system correctly

• In order to prevent noise inter ferences

a) Mains / supply lines,

b) Motor lines from inverters and servo controllers

c) Control and data lines (low voltage levels < 48 V), must have a clearance

of at least 15 cm when intalled.

• In order to maintain low-resistance high frequency connections, earthing and

shielding, as well as other metallic connections (e.g. mounting plate, installed

units) must be in metal-to-metal contact with the mounting plate, with a large

contact surface. Use earthing and equipotential lines with a section as large

as possible (min. 10 mm²) or use thick earthing strips.

• If external interference suppression filters are used, then these must be installed

as close as possible to (<30cmfrom) the interference source and in metal-to-

metal contact with the mounting plate, with a large contact surface.

• Always equip inductive control elements (contactors, relays etc.) with

suppressors such as varistors, RC-elements or damping diodes.

• All connections must be kept as short as possible and as close as possible to

the earth, as free lines work as active and passive antennas.

• Shielded cables should be used if the connecting lines between interference

suppression filter and commutating choke or commutating choke and R4-S-

regenerative unit are longer than 30 cm. The maximum length of this lines is

1 m.

• Keep connection cables straight (do not bundle). Connect all non-assigned

wire on both sides to the protective conductor.

• The flow and return circuit must be twisted when the lines are not shielded, in

order to dampen common-mode noise.

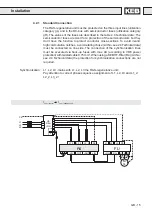

See the following pages for a correct intallation and wiring of an EMC control

cabinet.

Installation