Brake control and temperature detection | 9

ma_dr_f6-cu-a-inst-20118593_en

35

9.2 Temperature detection

GEFAHR

Electric shock by sensors without protective separation!

a) Only use sensors with basic insulation.

b) Only sensors with double insulation (basic insulation plus additional insulation)

are permitted up to the specified year/week of manufacturing (see specifica-

tion).

ACHTUNG

Malfunctions due to wrong cables or laying!

Malfunctions of the control due to capacitive or inductive coupling

a) Do not lay the cables of the motor temperature sensor (also shielded) together

with the control cables.

b) Cables of the motor temperature sensor within the motor cables are only per-

missible with double shielding.

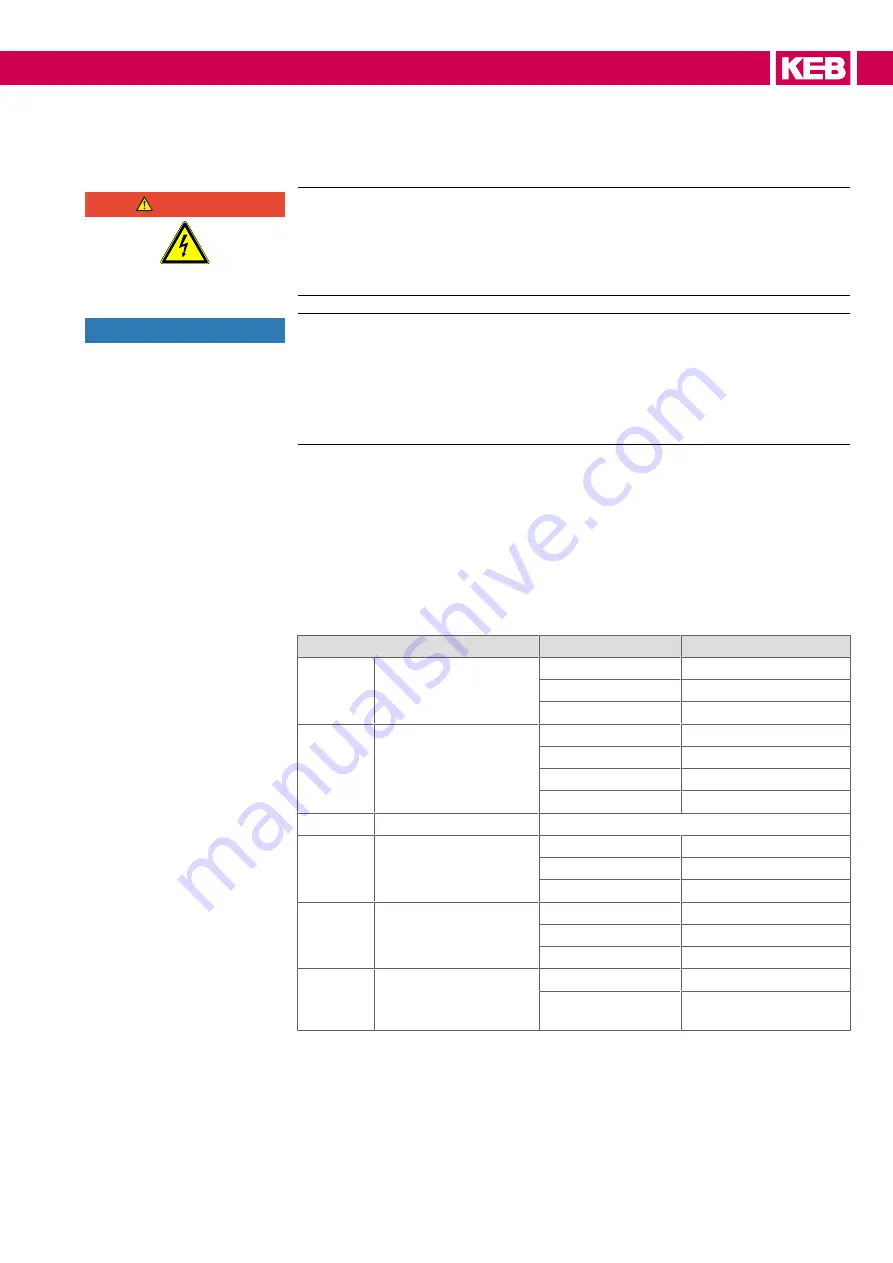

Specification temperature input

Name

TA1; TA2

Terminals

X1C.5 (TA1) input +

X1C.6 (TA2) input -

Function

Temperature sensor input (switchable)

Others

to the SELV voltage of the control card. A

system voltage of 300 V is defined (Phase – PE).

A switchable temperature evaluation is implemented in COMBIVERT. The desired

operating mode can be adjusted by software (dr33).

Operating mode (dr33)

Resistance

Temperature/state

0

KTY84/130

0.49 kΩ

0 °C

1 kΩ

100 °C

1.72 kΩ

200 °C

1

PTC in accordance with

EN 60947-8 (standard)

<0.75 kΩ

TA1-TA2 closed

0.75…1.5 kΩ

Reset resistance

1.65…4 kΩ

Tripping resistance

> 4 kΩ

TA1-TA2 open

2

by encoder

digital by the encoder channel

3

KTY83/110

0.82 kΩ

0 °C

1.67 kΩ

100 °C

2.53 kΩ

175 °C

4

PT1000

1 kΩ

0 °C

1.38 kΩ

100 °C

1.75 kΩ

200 °C

-

Monitoring

<0.04 kΩ

Short circuit

> 79.5 kΩ

No connection

(sensor break)

9.2.1 Operation without temperature detection

Use of the COMBIVERT without evaluation of the temperature input:

Switch off evaluation (pn33 =7) or install bridge between terminal TA1 (X1C.5) and

TA2 (X1C.6) (dr33=1).