72

cONNecTION OF THe POWer UNIT

NOTICE

Malfunctions due to incorrect line or laying!

Malfunctions of the control due to capacitive or inductive coupling.

►

Do not route cables from the motor temperature sensor (also shiel-

ded) together with control cables.

►

Cables from the motor temperature sensor within the motor cables

may only be used with double shielding!

►

The input of the temperature detection has basic isolation.

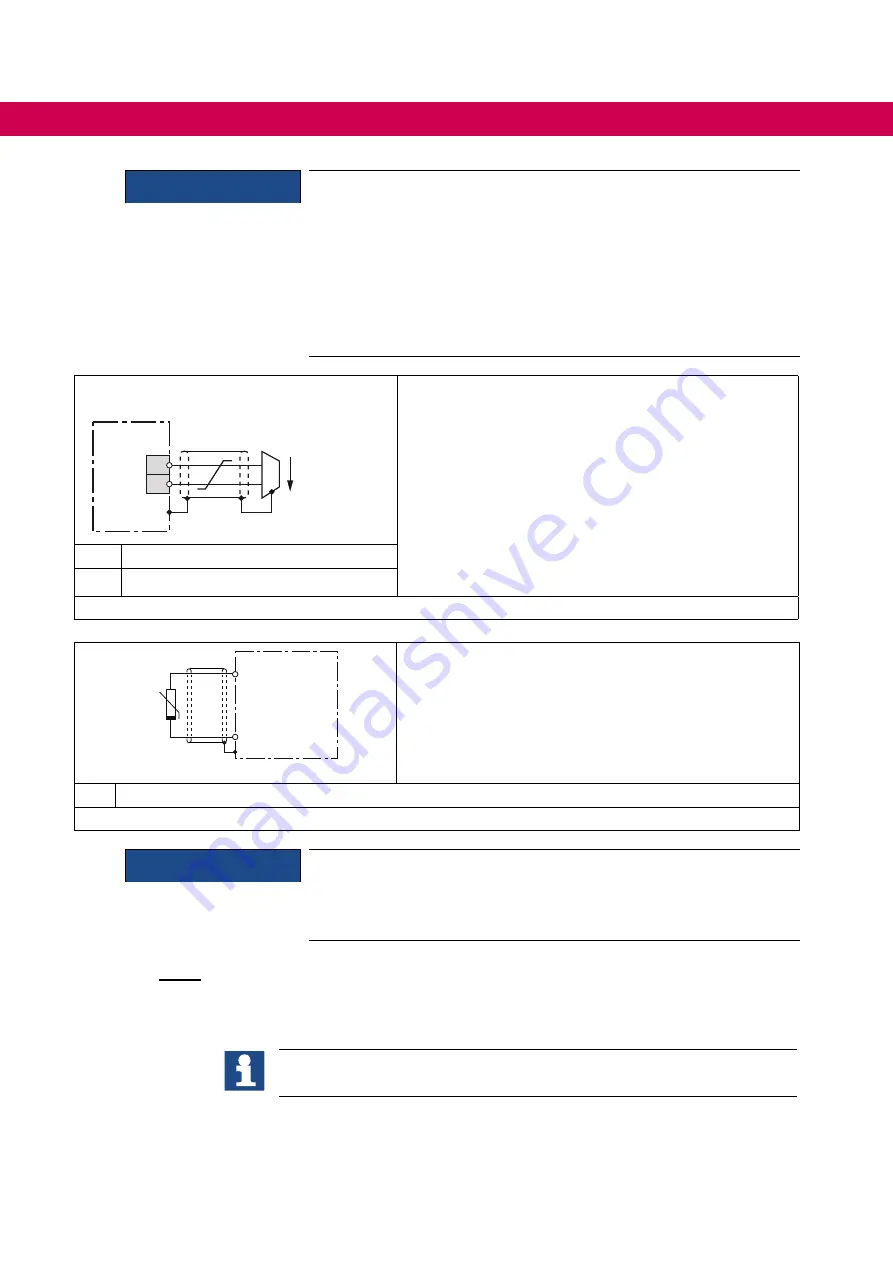

1

2

X1C

➀

➃

U

dc

= 24V

I

max

= 2A

For control board APPLICATION and COMPACT.

The voltage to the control of a brake is decoupled from the

internal voltage supply. The brake works only with external

voltage supply.

For control board PRO

The brake can be supplied with both, internal and external

voltage. Voltage tolerances and output currents vary for

internal and external voltage supply..

Respect the specifications

instruction manual „control board“

①

COMBIVERT

④

Brake

Figure 27:

Connection of the brake control

TA1

TA2

+

KTY84

①

KTY sensors are polarized semiconductors and must be

operated in forward direction! To this connect the anode

to TA1 and the cathode to TA2! Non-observance leads to

incorrect measurements in the upper temperature range.

A protection of the motor winding is then no longer guaran-

teed.

①

Connection via shield plate (if not available, place on the mounting plate).

Figure 28:

Connection of a KTY sensor

NOTICE

No protection of the motor winding in case of wrong connection.

►

Operate KTY sensors in forward direction.

►

KTY sensors may not be combined with other detections.

NOTE

„Basic insulation“ against SELV voltage of the control. A system voltage (Phase – PE) of

300 V is defined. Consequently, the connected sensors also must have a „basic insula

-

tion“ to the mains potential (e.g. motor winding)!

More information about the wiring of the temperature monitoring and the brake

control are described in the respective control unit manual.

Summary of Contents for COMBIVERT 10F6 Series

Page 2: ......

Page 82: ...82 NOTES...