9

1

KEB COMBIVERT F5

6

Name: Basis

04.05.04

Error Assistance

Chapter

Section

Page

Date

©

KEB Antriebstechnik, 2002

All Rights reserved

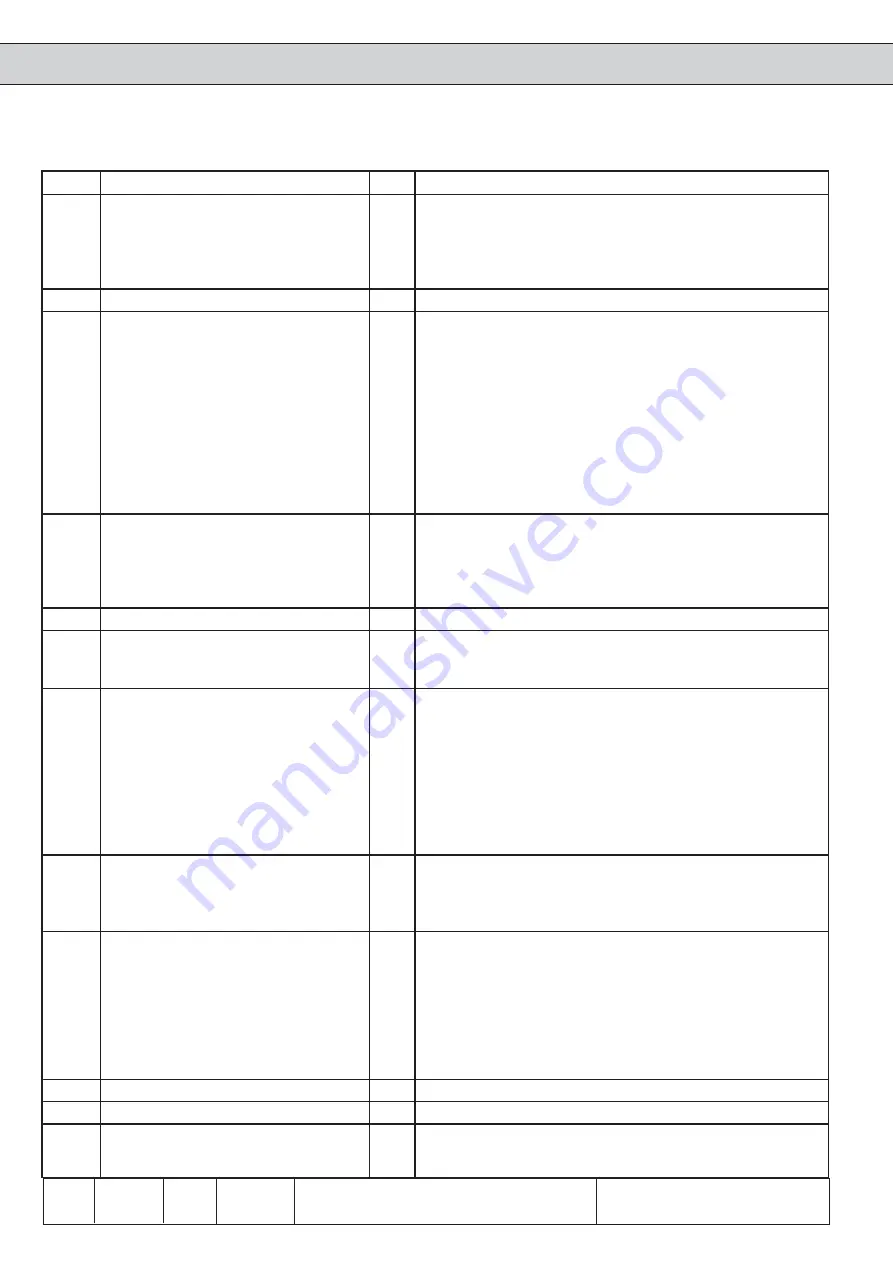

E.nOL

no ERROR overload

17 No more overload, OL-counter has reached 0%; after the

error E. OL a cooling phase must elapse. This message

appears upon completion of the cooling phase. The error can

be reset. The inverter must remain switched on during the

cooling phase.

E.nOL2 no ERROR overload 2

20 The cooling time has elapsed. The error can be reset.

E. OC

ERROR overcurrent

4 Error: Overcurrent

Occurs, if the specified peak current is exceeded. Causes:

• acceleration ramps too short

• the load is too big at turned off acceleration stop and turned

off constant current limit

• short-circuit at the output

• ground fault

• deceleration ramp too short

• motor cable too long

• EMC

• DC brake at high ratings active (see 6.9.3)

E. OH

ERROR overheat pow.mod.

8 Error: Overtemperature of power module. Error can only be

reset at E.nOH. Causes:

• insufficient air flow at the heat sink (soiled)

• ambient temperature too high

• ventilator clogged

E.OH2

ERROR motor protection

30 Electronic motor protective relay has tripped.

E.OHI

ERROR overheat internal

6 Error: Overheating in the interior: error can only be reset at

E.nOHI, if the interior temperature has dropped by at least

3°C

E. OL

ERROR overload (Ixt)

16 Error: Overload error can only be reset at E.nOL, if OL-

counter reaches 0% again.

Occurs, if an excessive load is applied longer than for the

permissible time (see technical data). Causes:

• poor control adjustment (overshooting)

• mechanical fault or overload in the application

• inverter not correctly dimensioned

• motor wrongly wired

• encoder damaged

E.OL2

ERROR overload 2

19 Occurs if the standstill constant current is exceeded (see

technical data and overload characteristics). The error can

only be reset if the cooling time has elapsed and E.nOL2 is

displayed.

E. OP

Error! Overvoltage

1 Voltage in the DC-link circuit too high.

Occurs if the DC-link circuit voltage exceeds the permissible

value. Causes:

• poor controller adjustment (overshooting)

• input voltage too high

• interference voltages at the input

• deceleration ramp too short

• braking resistor defective or too small

E.OS

ERROR over speed

58 Real speed is bigger than the max. Output speed.

E.PFC

ERROR Power factor control

33 Error in the power factor control

Display COMBIVIS

Value Meaning