Fieldbus interfaces | 7

ma_dr_f6-cu-p-inst-20182705_en

29

7 Fieldbus interfaces

7.1 Type code fieldbus

A CAN interface is integrated in the control unit as standard. Other fieldbus inter-

faces are identified by the 10th digit of the material number.

10. digit

Control board variant

3

PRO | Multi encoder interface,

, Ethernet fieldbus interface, RS485

potential-free

4

PRO | no encoder interface,

, Ethernet fieldbus interface, safe relay

5

PRO | Multi encoder interface,

, Ethernet fieldbus interface, safe re-

lay

7.2 CAN

Specification

Fieldbus type

Transmission level

According to DIN ISO 11898; ISO High

Speed

Transmission speed

20, 25, 50, 100, 125, 250, 500, 1000

kbit/s; adjustable via (fb66)

Potential separation

Functional insulation between CAN ter-

minals and to the control potential.

Bus termination

120 Ω external between (CAN High and

CAN Low) at both ends of the bus line.

Connection

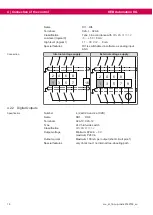

X2A.23

X2A.24

X2A.25

CAN_L

CAN_H

CAN_GND

CAN_L

CAN_H

CAN_GND

120Ω

120Ω

Abb. 3:

Connection CAN bus

Clamp Name

Note

X2A.23 CAN low

No internal bus termination

X2A.24 CAN high

X2A.25 CAN GND

CAN ground (can be wired depending on the cus-

tomer subscriber)

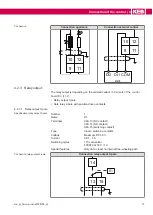

NET ST - LED in CAN mode

According to CiA 303-3, the NET ST LED is a combination of RUN and ERROR

LED.

Light pattern NET ST LED (red/

green combination)

Status

Light pattern

Description

Pre-Op

g-0 (grid 200 ms)

Device in PRE-OPERA-

TIONAL status

Stop

g-0-0-0-0-0 (grid 200 ms)

Device in STOPPED

status