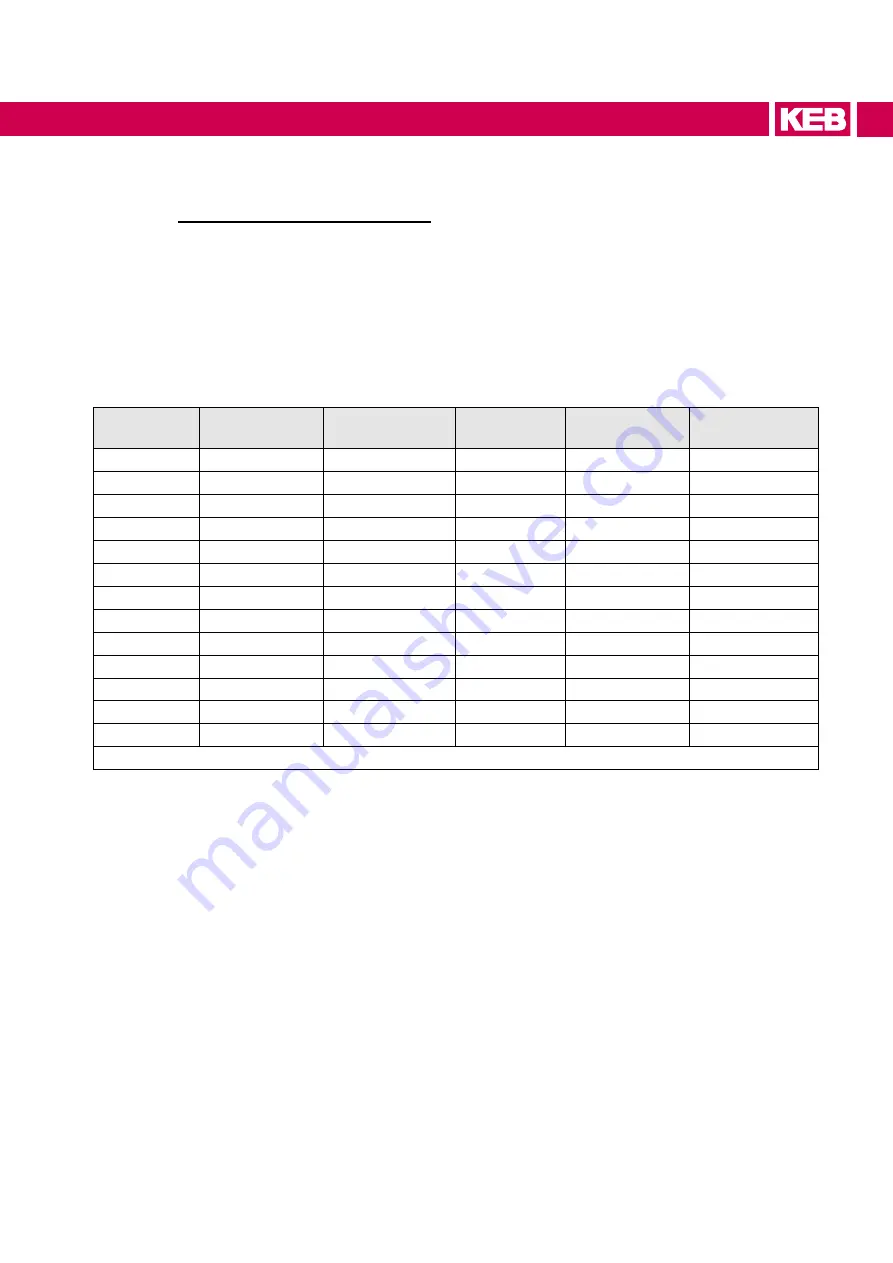

3.2.7.2 Materials in the cooling circuit

Avoid contact corrosion and pitting

For the screw connections and also for the metallic articles in the cooling circuit which

are in contact with the coolant (electrolyte) a material is to be selected, which forms a

small voltage difference to the heat sink in order to avoid contact corrosion and/or pitting

corrosion (electro-chemical voltage series, see the following table). The specific case of

application must be checked by the customer in tuning of the complete cooling circuit

and must be classified according to the used materials. With hoses and seals take care

that halogen-free materials are used.

A liability for occuring damages by wrongly used materials and from this resulting corro-

sion cannot be taken over!

Material

formed ion

Standard poten-

tial

Material

formed ion

Standard poten-

tial

Lithium

Li+

-3.04 V

Nickel

Ni2+

-0.25 V

Potassium

K+

-2.93 V

Tin

Sn2+

-0.14 V

Calcium

Ca2+

-2.87 V

Lead

Pb3+

-0.13 V

Sodium

Na+

-2.71 V

Iron

Fe3+

-0.037 V

Magnesium

Mg2+

-2.38 V

Hydrogen

2H+

0.00 V

Titan

Ti2+

-1.75 V

Stainless steel

various

0.2...0.4 V

Aluminium

Al3+

-1.67 V

Copper

Cu2+

0.34 V

Manganese

Mn2+

-1.05 V

Carbon

C2+

0.74 V

Zinc

Zn2+

-0.76 V

Silver

Ag+

0.80 V

Chrome

Cr3+

-0.71 V

Platinum

Pt2+

1.20 V

Iron

Fe2+

-0.44 V

Gold

Au3+

1.42 V

Cadmium

Cd2+

-0.40 V

Gold

Au+

1.69 V

Cobald

Co2+

-0.28 V

Table 19: Electrochemical series / standard potentials against hydrogen

47

SYSTEM AND MODULE DATA

Summary of Contents for COMBIVERT T6APD

Page 2: ......