4.3.2.5 Motor cable length

The maximum permissible resulting motor cable length per inverter module is 30 m.

Longer cables, standard cables with a larger capacitive coating against shield / PE and

cables with much bigger cross-section than required can:

• Reduce the overcurrent capability of the inverter.

•

Have a negative influence on the interference behaviour (radiation and cable-fed volt

-

age).

• Damage the device if necessary.

The resulting motor cable length for parallel operation of motors, or parallel installation

with multiple cables arises from the following formula:

resulting motor cable length = ∑single cable lengths x √

N

umber of motor cables

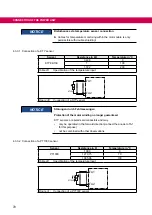

4.3.2.6 Interconnection of the motor

NOTICE

Incorrect behavior of the motor!

►

The connection instructions of the motor manufacturer are always

generally valid !

NOTICE

Protect motor against voltage peaks!

►

Drive inverters switch at the output with high dV/dt. Voltage peaks

that endanger the insulation system at the motor can occur espe-

cially in case of long motor cables (>15 m).

NOTICE

Connection of the drive in star connection!

►

The star point must not be earthed.

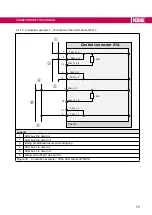

4.3.3 Temperature detection

The COMBIVERT T6

APD

has implemented a switchable temperature detection. The in-

put has basic isolation. The operating mode can be selected by software. The operating

mode can be used for the following functions:

function

Temperature detec-

tion

Motor temperature display and monitoring

KTY84

Motor temperature display and monitoring

PT1000

Motor temperature monitoring

PTC

General error detection

PTC

Table 22:

Possible applications of temperature detection

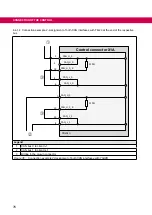

„basic insulation“ against SELV voltage of the control

A system voltage (Phase – PE) of 300 V is defined. Consequently, the con

-

nected sensors also must have a „basic insulation“ to the mains potential (e.g.

motor winding).

69

CONNECTION Of THE POWER UNIT

Summary of Contents for COMBIVERT T6APD

Page 2: ......