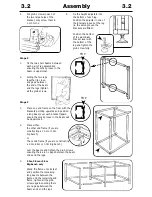

Stage 1

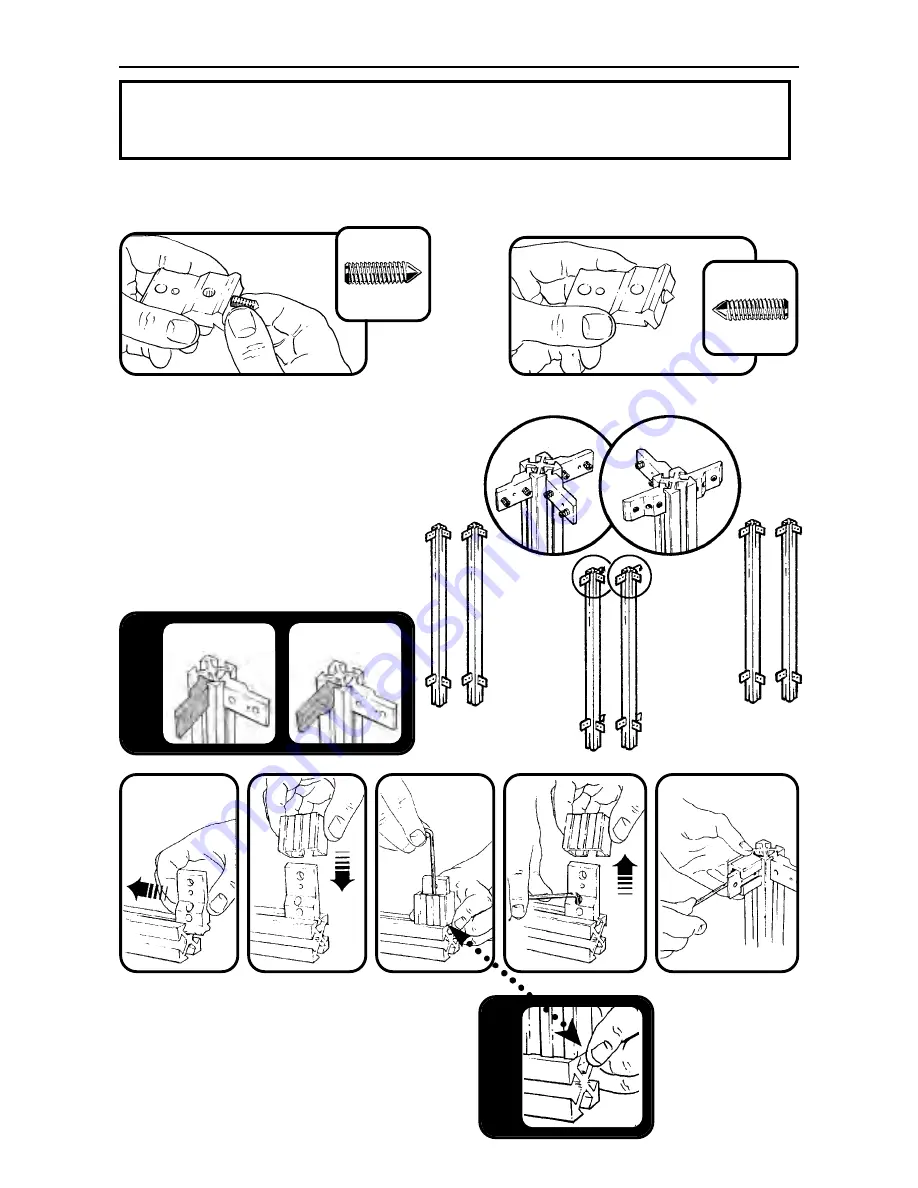

1.

Put a grub screw backwards into each of the joining brackets – do not place screws in the

other holes.

NOTE:

The following instructions will assume the Big bench has six legs (2.0, 2.5 or 3.0). If

you are constructing a (1.0 or 1.5) Big bench please omit the middle frame.

✗

✗

✗

✓

➤

a

2.

Using the spacer, fit the brackets to the top of

each leg as shown – ensure:

a).

The brackets are fitted the correct

way round.

b).

The spacer is slightly above the top

level of the leg, so when

constructed the top level of the leg

is not above the beam.

c).

The grub screws are tightened fully.

3.

Attach brackets to the

bottom of the legs (and the

same way round as shown

above), using a tape measure

or spacer to position them to

suit your requirements.

a

✗

✔

3.1

Assembly

3.1