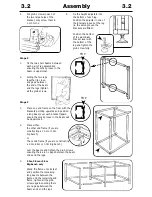

Stage 2

1.

Fit the two short beams between

each pair of leg assemblies

ensuring the small groove in the

beam is uppermost.

2.

Pulling the two legs

together (to close

any gaps between

the end of the beam

and the legs) tighten

all the grub screws.

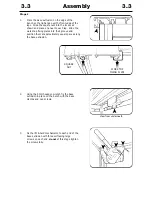

Stage 3

1.

Place one end frame on the floor with the

brackets pointing upwards and position

a long beam over each bracket (again

ensure the small groove in the beam will

be uppermost).

2. Place either:

the other end frame (if you are

constructing a 1.0m or 1.5m

big bench)

or

The centre frame (if you are constructing

a 2.0m, 2.5m or 3.0m Big bench)

over the beams and tighten the grub screws

ensuring there are no gaps between the beam

ends and the legs.

3.

2.0m, 2.5m or 3.0m

Big bench only

Stand the frame onto its feet

and position the remaining

long beams between the

frame and the remaining end

frame, tighten all the grub

screws again ensuring there

are no gaps between the

beam ends and the legs.

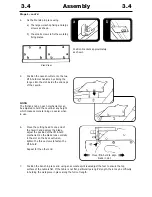

TOP

3.2

Assembly

3.2

4.

Put grub screws in each of

the two large holes of the

bracket, only screw them in

2 or 3 turns.

5.

Fix the height adjusters into

the bottom of each leg.

Position the adjuster in one of

the internal grooves of the leg

(ie. the same groove the

brackets are fitted).

Position the bottom

of the aluminium

bracket level with

the bottom of the

leg and tighten the

grub screw fully.

TOP