b

a

3.4

Assembly

3.4

Stage 4 – cont’d

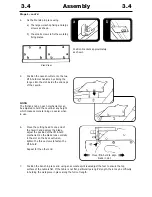

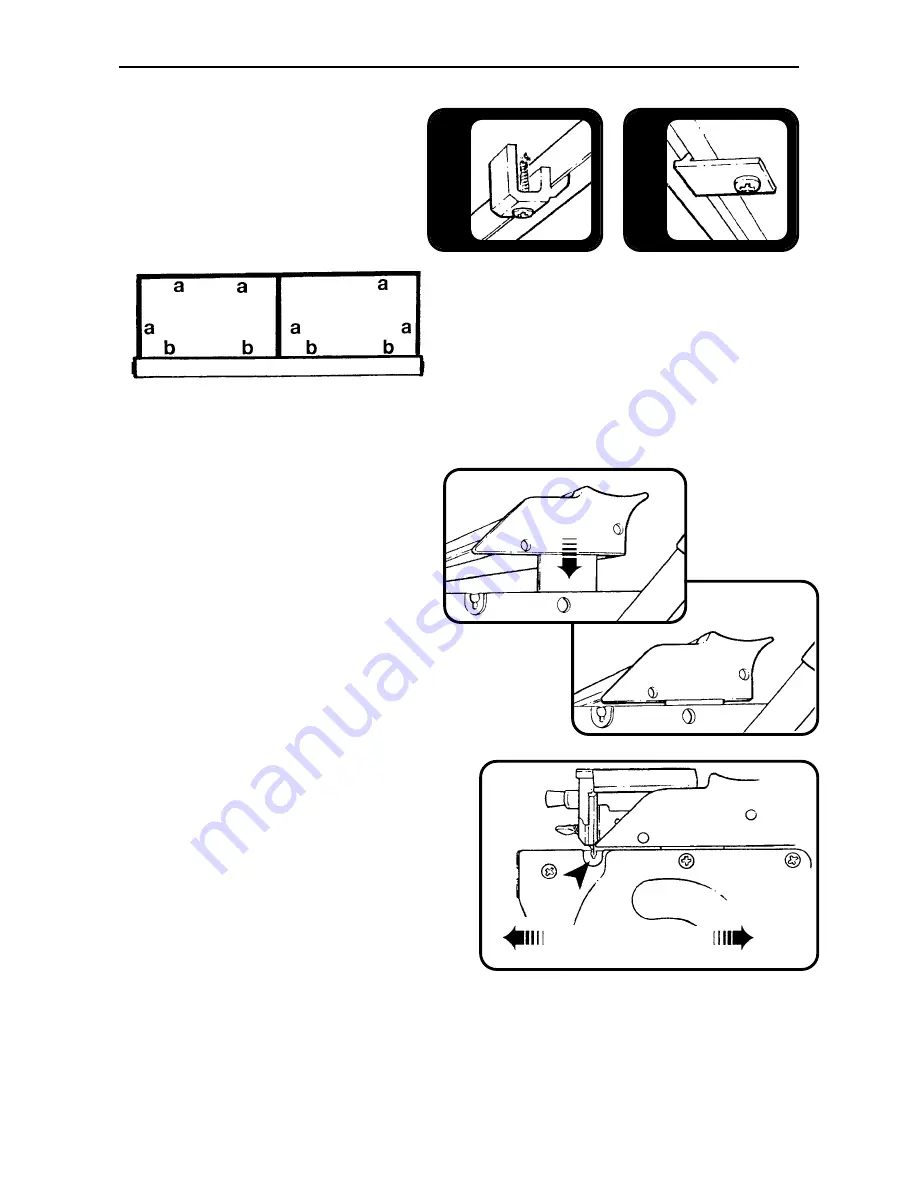

4.

Fix the Worktop in place using

a) The large workshop fixing and large

screws as shown.

b)

the small screws to fix the worktop

fixing plates.

5.

Position the Javelin cutter onto the two

lift & hold mechanisms by sliding the

tongue into the slot inside the end caps

of the Javelin.

6.

Move the cutting head to one end of

the Javelin and depress the blade,

adjust the position of the lift & hold

mechanism so the blade runs centrally

in the slot on the base extrusion,

tighten the three screws to fasten the

lift & hold.

Repeat for the other end.

Move lift & hold to align

blade in slot

Position brackets approximately

as shown

NOTE:

The friction knob on each mechanisms can

be adjusted to hold the Javelin at any height

which makes accurate lining up easier when

in use.

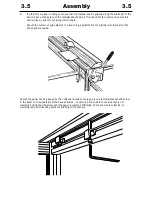

7.

Position the bench in place and using an accurate spirit level adjust the feet to ensure the top

surface of the table is flat. If the table is not flat, particularly along it’s length, there may be difficulty

in holding the workpiece in place along the full cut length.

Plan View