Worktop Material Guide Installation

Manual

The world’s finest cutting machines

www.keencut.com

+44 (0) 1536 263158

+1 (716) 748 6203

sales@keencut.co.uk (UK HQ)

sales@keencut.com (US sales)

Scan the QR code or

click here to view this document online >

Page 8 of 17

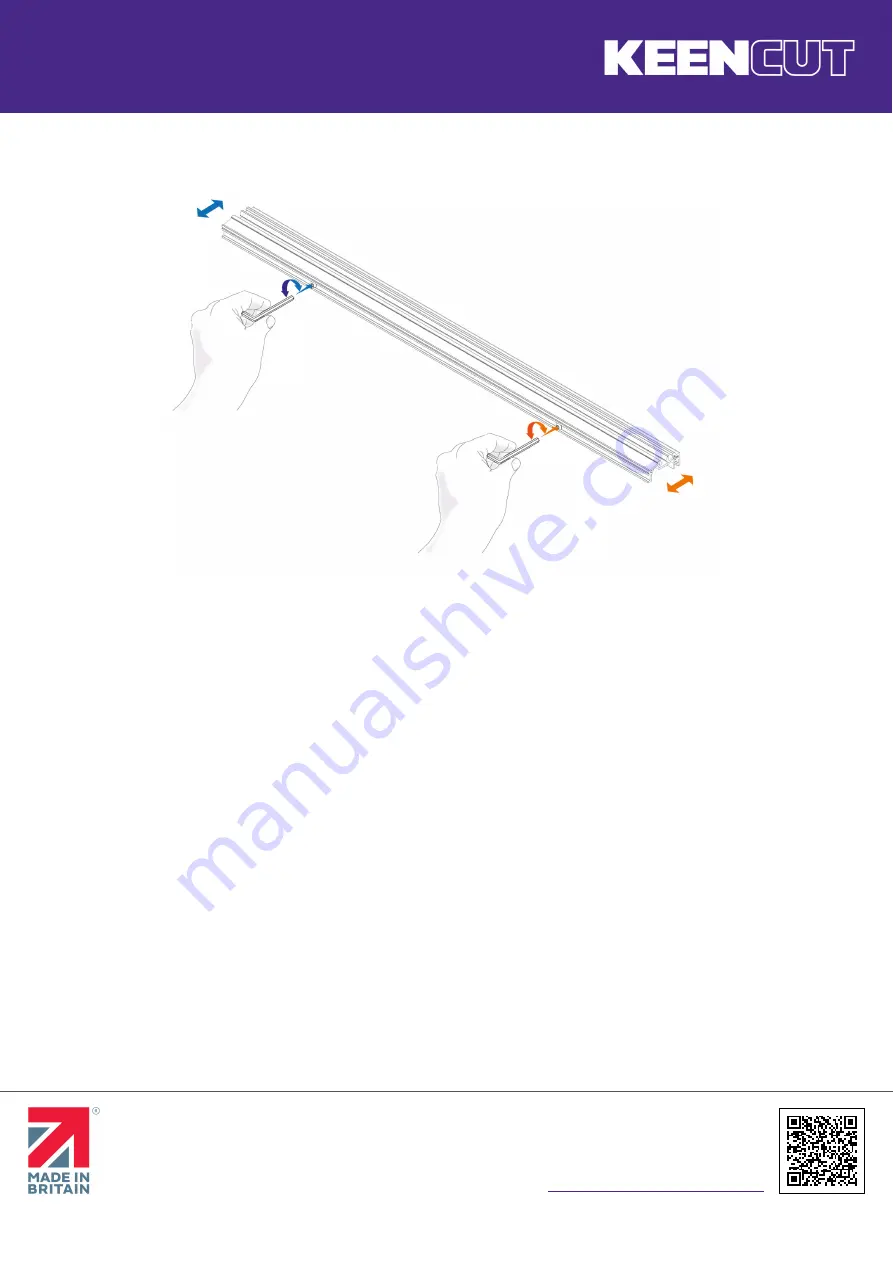

2.3 Fine adjustment

Fine squaring corrections can be made using a 4mm Allen (hex) in the two squaring adjusters.

Firstly, make any required adjustment to the angle of the Material Guide. This can be carried out using either adjustment

screw. When turning the screw clockwise the Material Guide at that point advances, rotating the guide about the other

adjuster.

Need help checking it is at 90 degrees when installed with a cutter? Go to

Once the angle has been adjusted, if the Material Guide needs to move parallel to align with another object/edge rotate

both screws by equal amounts. As a guide, one full rotation of the screw equals 1mm (0.040”).