1.

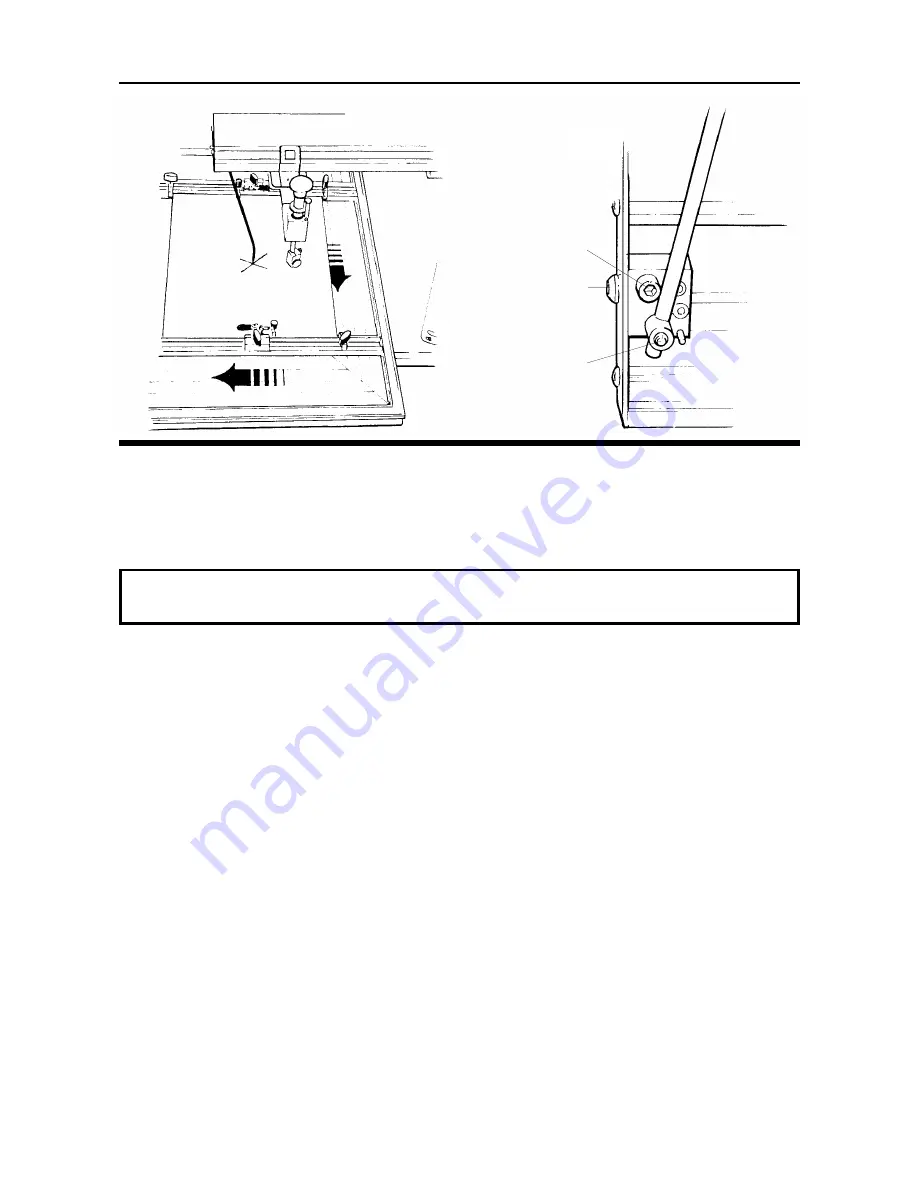

Using the centre pointer

The centre pointer indicates the centre of rotation of the turntable to enable the

matboard to be placed without using the scales on the turntable. It is used for

precise positioning when cutting multiple openings. The centre pointer should be

pivoted into its park position under the beam when not in use.

NOTE: When using or setting the centre pointer always set the differential scale to the

circle setting or position the turntable at 90° to the beam (portrait position).

1.1

Mark the centre position of the oval or circle on the matboard.

1.2

Swing the centre pointer from under the beam until it stops.

1.3

Place the matboard so that the centre mark is under the centre pointer.

1.4

Move the clamps to secure the board and cut the opening.

2.

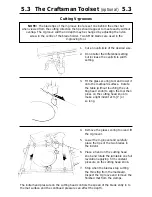

Adjusting the centre pointer for accuracy

The printed turntable grid is correctly installed when the centre lines align with the

zero points on the turntable edge scales. The centre pointer should exactly

indicate the crossed centre lines on the turntable grid when the differential scale

is set to cut a circle or the turntable is in the ‘portrait position’.

Set the differential scale to the circle position and swing the centre pointer into

position. If the centre pointer appears to point to the centre of grid rotate the

turntable and check that it does so for a complete revolution. If it does not

proceed as follows:-

2.1

Lift the beam.

2.2

Observe the socket screw with an eccentric head

which limits the travel

of the centre finder. Fix the 5mm hexagon wrench to it and lower the beam.

2.3

Adjust the pointer laterally by turning the eccentric screw until the pointer is

at the centre of the grid.

2.4

If adjustment front to back is necessary first lift the beam and observe the

small screw

in the end of the pivot which locks the pointer in place. Fit

3mm hexagon wrench and loosen it.

2.5

Lower the beam and adjust the pointer until it is at the centre of grid, lock

the screw.

2.6

The height of the pointer can be adjusted using screw

.

4.5

Operation

4.5

The Centre Pointer