7.1

4

Maintenance

7.1

4

Planned Maintenance Chart

Frequency: After 2 weeks of use and then every month thereafter

Adjust clamp pressure (page 7.1

2

.)

Check clamp alignment (page 7.1

2

.)

Check guide wheel adjustment (page 7.1

3

.)

Lubricate Guide rods & rollers (page 7.1

1

.)

Lubricate Ratchet system (page 7.1

1

.)

Lubricate Balance weight (page 7.1

1

.)

Lubricate Ratchet release bar (page 7.1

1

.)

Lubricate Swinging Arm (page 7.1

1

.)

In the first few weeks the clamp with

bed itself in and will need adjusting.

See instructions on page 7.1

1

.

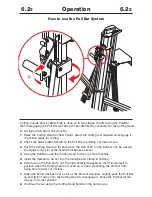

Using 2 pieces of A4 paper, place

one under the bottom end of the

clamp and hold the other at the top

end whilst depressing the clamp

handle, check that the clamp firmly

grips both pieces of paper. If not the

clamp will need aligning as above.

This should never go out of adjust-

ment but is wise to check.

Wipe using cleaning solvent on a

cloth, and lubricate the surfaces very

lightly with petroleum jelly. The axles

of the rollers are lubricated and

sealed for life and need no further

attention.

Use a light oil (3 in 1), one or two

drops on the pivot point and one

drop on the ratchet teeth

Silicon Lubricant sprayed in from the

top of the balance weight opening

whilst the cutting head is parked at

the top of the machine

Smear edge with petroleum jelly

Petroleum jelly around curved slot.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920