·

18

·

Transport robots

Therobotis valuableequipment, pleasestrictly followthe below

instructionsto operate whenneed manual transport robots.

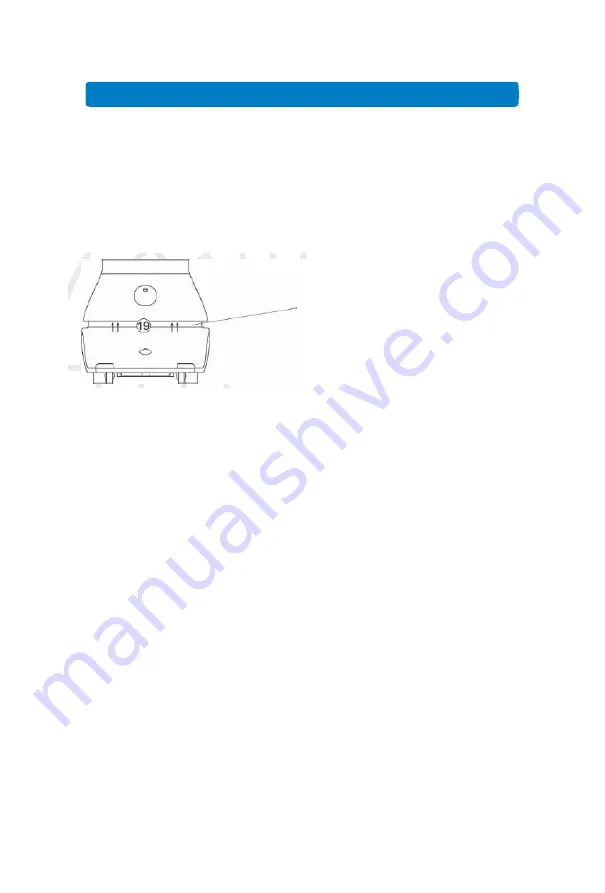

Shown as picture 6, the up part (The arrow appointed surface) at robot laser

layer gap can be stressed, you can up lift the robot through these part. Please use

hand lift the up part of laser layer when transporting, please note that always

keep robot be at up-right gesture during transporting.

Note:should use hand buckle the laser

layer gap between body and base

during transporting the robot.

Picture 6 Transporting diagram

* Note:

The above laser layer gap is the only one stressed part for transporting. Please

transporting robot strictly follow the instruction. Strictly forbid directly drag and lift

the bottom o

f robot during transporting; strictly incline the robot; strictly forbid directly

drag and lift face and head of robot. Users self duty for the damage of robot which

caused by the incorrect operation during transporting.

Summary of Contents for PEANUT

Page 1: ...PEANUT intelligent transporting robots Product specification...

Page 6: ...7 to...

Page 7: ...8 the entity...

Page 10: ......