KH10.0 10,000 LBS. REPLACEMENT HYDRAULIC WINCH

KH10.0 10,000 LBS. REPLACEMENT HYDRAULIC WINCH

SAFETY WARNINGS AND PRECAUTIONS

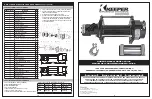

WORKING HYDRAULIC PRINCIPLE CHART

INSTALLATION ILLUSTRATION (Complete working mode)

WINCH WARNINGS AND PRECAUTIONS

INSTALLATION

UNPACKING

Warning:

When using a winch, basic safety precautions should always be followed to reduce the risk of personal injury and damage to the

equipment. Read all these instructions before using this tool!

1. Keep children away.

Children must never be allowed in the work area. Do not let them handle machines, tools, or extension cords.

2. Dress properly.

Do not wear loose clothing or jewelry as they can be caught in moving parts. Protective, electrically

nonconductive clothes and non-skid footwear are recommended when working. Wear restrictive hair covering to contain long hair.

3. Stay alert.

Watch what you are doing, use common sense. Do not operate your winch when you are tired.

4. Check for damaged parts.

Before using your winch, any part that appears damaged should be carefully checked to determine

that it will operate properly and perform its intended function. Check for alignment and binding of moving parts, any broken parts

or mounting fixtures, and any other condition that may affect proper operation. Any part that is damaged should be properly repaired

or replaced before use. Do not use the winch if any switch is not working properly.

5. Replacement parts and accessories.

When servicing, use only identical certified parts. Call 1-800-533-7372 for parts and service.

6. Do not operate winch if under the influence of alcohol or drugs.

Read warning labels on prescription to determine if your

judgment or reflexes are impaired while taking the prescription. If there is any doubt, do not operate the winch.

Simple Working Mode

1. Hydraulic power from a suitable individual pump

2. Hydraulic power from a combined pump

Complete Working Mode

1.

Keep hands and body away from roller fairlead when operating.

2.

Secure vehicle in position before using your winch.

3.

Be certain your winch is properly bolted to a structure (or vehicle) that can hold the winch load.

4.

Do not use improper attachment to extend the length of the winch cable.

5.

Never lift people or hoist loads over people.

6.

Never come between your winch and the load when operating your winch.

7.

Do not apply load to winch when cable is fully extended. Keep at least 5 full turns of cable on the reel. (one layer)

8.

After moving an item with your winch, secure the item. Do not rely on your winch to hold it for an extended period of time.

9.

Examine your winch before using. Components may be affected by exposure to chemicals, salts, and rust.

10.

Never fully extend cable while under load. Keep 5 complete turns of cable around the winch drum.

11.

Never operate your winch if the wire rope shows any signs of weakening, knotted or kinked.

12.

Winch does not have a locking mechanism, secure load after moving.

13.

Do not cross over or under the cable under load.

14.

Do not move vehicle with the cable extended and attached to load to pull it; the cable could fail.

15.

Use gloves while handing the cable.

16.

Apply blocks to the vehicle when parking on an incline.

17.

Re-spool cable evenly on drum.

1.

Your winch is designed as a replacement unit for an existing system and should bolt into place using your existing components.

If this is a new system installation, you may need additional components to properly complete the system (Fluid Supply Tank,

Balancing Valve, Directional Valve). See retailer for additional components to complete system.

2. Mount your winch to the vehicle using high strength cap screws. Your winch should be aligned and secured to a solid part of the

vehicle (front or rear) where the full rated load will be evenly distributed.

4. A Handheld Remote-Control kit is supplied if your system needs to be upgraded.

5. Please see the suggested installation diagrams below. These are only presented as examples. Your installation may vary depending

upon system set up and application.

If your application is supplied with an added cooler, please refer to illustration, check fluid level. Replace lost fluid to system. System will

need to be purged. Start engine. Power winch cable in 5 feet. Shut engine off. Check fluid level. (Add fluid until full, start engine, power

winch cable out 5 feet, shut engine off, check fluid level. ) Add fluid until full if necessary. Start engine. Power winch cable into desired

position. Turn vehicle wheels from lock to lock position 5 times. This will aid in bleeding out any air that may have gotten into the system.

If the control unit is working backwards, simply exchange the brown and white wire connectors. Winch cable must be wound onto the drum

under a load of at least 10% rated line pull or outer wraps will draw into inner wraps and damage winch cable.

When unpacking, check to make sure all parts are included. Refer to the winch assembly drawing and parts list at the end of this manual.

Steering

Box

Ground

12V / 24V

Winch

Reservoir

Pump

Motor

Cooler

Solenoid

Valve

Steering

Box

Balance Valve

A

B

S

P

S

A

P

B

T

Steering

Box

Balance Value

Directional

Value

S

C1

C2

A

P

B

T

Female

Male

A

B

Ground

12V / 24V

Winch

Resevoir

Pump

Directional

Valve

Motor

Cooler

Solenoid

Valve

Steering

Balance Valve

P

Female

Male

CAUTION!

!

!

PLUMBING CONNECTIONS

Keep all hoses away from any areas where heat may be considered too extreme such as an exhaust manifold or turbo. Lines should not be allowed to rub

on any abrasive or vibrating surfaces. In some applications, 90o fittings on the directional valve and motor or balance valve are necessary to make hose

mounting more flexible. After plumbing has been laid out on your vehicle, install and tighten O-Ring fittings supplied to valve. DO NOT OVERTIGHTEN ANY

FITTINGS. Install and tighten O-ring fittings on winch motor. Connect any hose port A on motor or port on balance valve to port A on directional valve, port B

on motor or port on balance valve to port B on directional valve, port P on directional valve to pump’s high pressure port, port T on valve to reservoir.

Test winch for proper operation. Refer to the operation section, below.

2

3