GENERAL INFORMATION

MAINTENANCE

The winch’s standard equipment contains gear reducer, drum, hydraulic motor, switch assembly, and plumbing fittings. The winch obtains its

pressure from the vehicle’s existing hydraulic power. The winch is totally sealed, and can be used underwater.

There are several ways to supply the pressure for your winch; the first way (1) is to use an individual pump, and the second way (2) is use

the vehicle’s existing power steering pump as shown in the installation instruction. (1) Use a suitable individual pump which has no oil

valve; it supplies pressure to both steering box and winch. (2) Use a combined pump, which integrates an oil valve; the oil valve supplies

two kinds of flow for difference demand, one with constant flow is for steering use, the other with higher power is for engineering use. Refer

to installation illustration. You can choose the most suitable way.

If your winch is installed in a simple working mode (standard supplied), NEVER POWER WINCH CABLE OUT WITH HEAVY LOAD, as it could be dangerous.

If your winch is installed with a balance valve in a complete working mode, you can power winch cable in and out under heavy load if needed.

1.

Disengage the clutch by turning the clutch to the “OUT” position.

2.

Grab the cable assembly hook and pull the cable to the desired length, then attach to the item being pulled.

CAUTION:

Always leave at least five turns of cable on the drum; review winch safety warning and precautions on pages 2 and 3 before continuing.

3.

Reengage the clutch by turning the clutch to the “in” position. If necessary, turn the drum to make a slight “click” sound while

engaged properly, make sure the clutch lever is down and fully seated.

4.

While standing safely aside of the tow path, press (and hold) the red push button on the switch assembly. Press (and hold) the

opposite push button to reverse direction. Wait until the motor stops before reversing direction.

5.

When the work is complete, remove the switch assembly from the female connector and replace the female connector cover.

TROUBLE SHOOTING

SYMPTOM

POSSIBLE CAUSE

SUGGESTED ACTION

• Winch does not turn.

• Electrical connections have not

connected properly.

• Insert switch assembly all the way into

connector.

• Tighten nuts on all cable connections.

• Motor runs but cable

drum does not turn.

• The clutch is not engaged.

• Turn the clutch to the “CLUTCH IN” position, if

problem still persists, a qualified technician

needed to check and repair.

• Winch drum runs

slowly or without

normal power.

• Insufficient pressure or oil flow.

• Balance valve connected with

wrong direction.

• Insufficient fluid in the system.

• Pump is not suitable or defective, change a new

one or a suitable one.

• Disconnect the balance valve; exchange the oil

hole between hydraulic motor and balance valve.

• Check fluid level and fluid until full.

• The switch assembly

working backwards.

• Electrical connections are in

wrong direction.

• Simply exchange the blue and yellow wire

connectors at the solenoid of directional valve.

WARNING!

1. Make sure clutch is totally engaged before starting any winch operation.

2. Stay clear and away from raised loads.

3. Stay clear of cable while pulling; do not try to guide cable.

4. Maintain a minimum of 5 wraps of cable around the drum barrel.

!

!

KH10.0 10,000 LBS. REPLACEMENT HYDRAULIC WINCH

KH10.0 10,000 LBS. REPLACEMENT HYDRAULIC WINCH

LUBRICATION

CABLE ASSEMBLY REPLACEMENT

1.

All moving parts within the winch having been lubricated using high temperature lithium grease at the factory. No internal

lubrication is required.

2. Lubricate cable assembly periodically using a light penetrating oil.

1.

Turning clutch to the “clutch out” position.

2. Extend cable assembly to its full length. Note how the existing

cable is connected to the drum.

3. Remove old cable assembly and attach new one.

4. Retract cable assembly onto drum while making sure the first five

wraps are carefully wound to not allow wire kinking or pinching.

Winch cable must be wound on the drum under a load of at least

10% rate line pull.

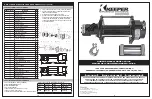

ITEM NO.

DESCRIPTION

QTY

1

Hexagon bolt M5 X 16

10

2

Spring Washer

10

3

Gear Box End Cover

1

4

Hexagon Bolt M8 X 20

6

5

Bearing

1

6

Spring Washer

4

7

Clutch Gear

1

8

Transmission Shaft

1

9

Planetary Gear Assembly 1

1

10

Plastic Washer

1

11

Planetary Gear Assembly 2

1

12

Hexagon Bolt M6X15

1

13

Clutch Handle

1

14

Clutch Handle Localizer Housing

1

15

Spring

1

16

Clutch Handle Localizer

1

17

Gear Box

1

18

Paper Washer

2

19

Gear Box Base

1

20

Spring Washer

10

21

Screw M6X16

10

22

Sliding Bearing

2

23

Hexagon Connector

1

24

Drive Shaft

1

25

Hoop 14.8mm X 11.9mm X 1mm

1

26

Drum

2

27

Tie Bar

2

28

Brake

1

29

Motor Base

1

30

Motor Ring Base

1

31

Hydraulic Motor

1

32

Spring Washer

2

33

Hexagon bolt M12 X 45

2

6.5"

6.75"

6.75"

10"

10"

21.75"

21.75"

5"

5"

4.5"

6.5"

218

TO-CLEAR

PERFORMANCE SPECIFICATIONS

Single line pull: 10,000 lbs.

Gear ratio: 88:1

Motor: Hydraulic motor

Brake: Automatic brake

Drum size: 2.5" x 8.8" (63.5 mm x 224 mm)

Cable: 3/8" x 85

'

(9.2 mm x 26 m)

Mounting bolt pattern: 10" x 4.5" (254 mm x 114 mm

Pull, speed, pressure, flow (first layer)

Line Pull

Pressure

Flow

Line Speed

Lbs

(Msa)/Psi

G/Min (L/min)

EPM (M/min)

0

(1.0) 145

5.3 (20)

2.3 (0.70)

8000

(5.0) 725

7.9 (30)

2.8 (0.85)

10,000

(7.0) 1,015

13.2 (50)

3 (0.90)

4

5