11

INSTALL ALL POWER, INTERCONNECTING

WIRING, AND PIPING TO INDOOR UNIT

1. Run interconnecting piping and wiring from outdoor unit to

indoor unit.

2. Pass interconnecting cable through hole in wall (outside to

inside).

3. Lift indoor unit into position and route piping and drain

through hole in wall (inside to outside). Fit interconnecting

wiring into back side of indoor unit.

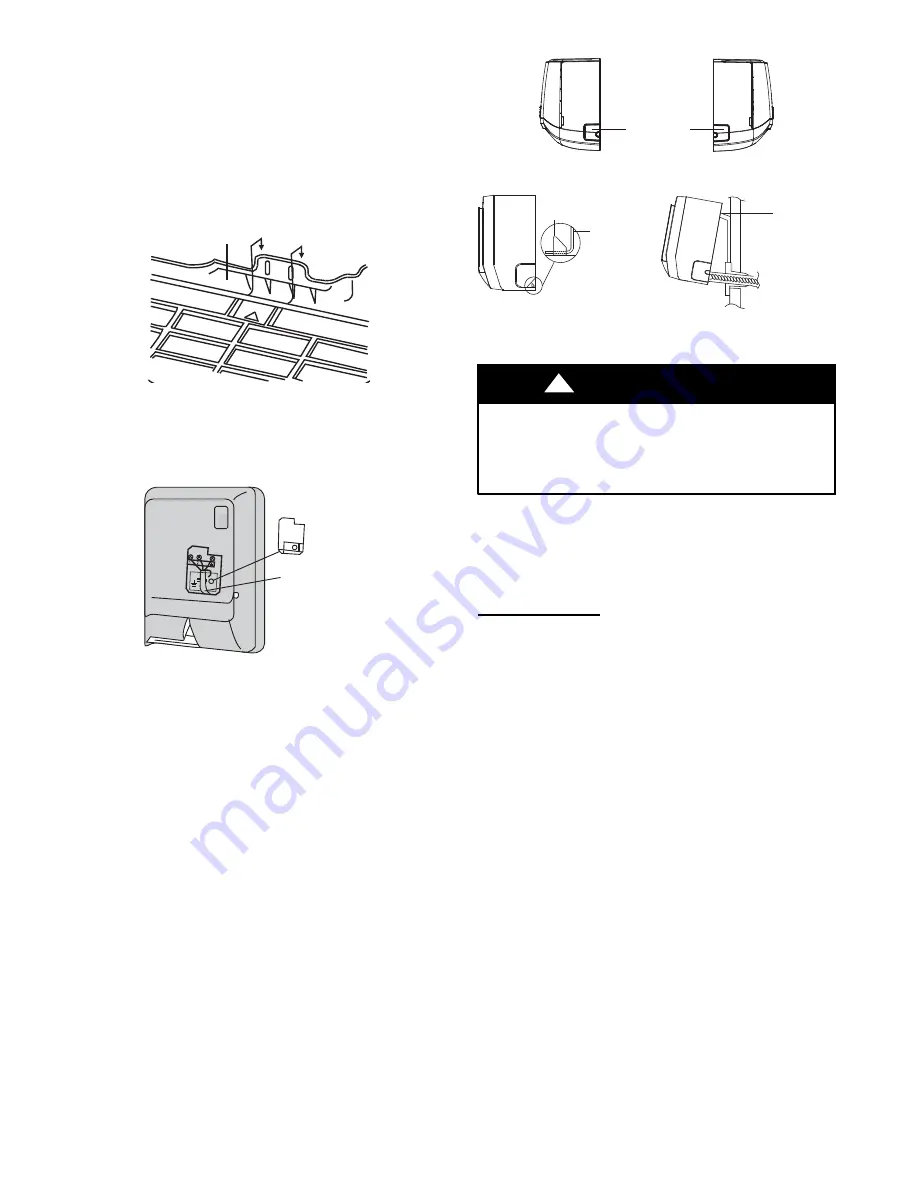

4. Hang indoor unit on upper hooks of wall mounting plate (as

shown in Fig. 12 and Fig. 15).

A08283

Fig. 12

-

Hanging Indoor Unit

5. Open front cover of indoor unit and remove field wiring ter-

minal block cover (see Fig. 13).

Field Wiring

Cover

Interconnecting

Cable

A08279

Fig. 13

-

Field Wiring Cover

6. Pull interconnecting wire up from back of indoor unit and

position in close to the terminal block on indoor unit.

7. Push bottom of indoor unit onto mounting plate to

complete wall mount.

8. Connect wiring from outdoor unit per connection diagram

(see Fig. 21).

NOTE

:

Polarity of power wires must match original

connection on outdoor unit.

9. Replace field wiring cover and close front cover of indoor

unit.

10. Connect refrigerant piping and drain line outside of indoor

unit. Refer to Fig. 9 for proper installation of flare

connections. Complete pipe insulation at flare connection

then fasten piping and wiring to the wall as required.

Completely seal the hole in the wall.

cut off

the hole

left

right

Fig. 14

-

Remove Knockouts

Mounting

plate

Fixing hook

Mounting

plate

A12408

Fig. 15

-

Hang Indoor Unit

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum pump.

CAUTION

!

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used if the procedure outlined

below is followed. Always break a vacuum with dry nitrogen.

SYSTEM VACUUM AND CHARGE

Using Vacuum Pump

1. Completely tighten flare nuts A, B, C, D, connect manifold

gage charge hose to a charge port of the low side service

valve (see Fig. 16.)

2. Connect charge hose to vacuum pump.

3. Fully open the low side of manifold gage. (See Fig. 17)

4. Start vacuum pump

5. Evacuate using either deep vacuum or triple evacuation

method.

6. After evacuation is complete, fully close the low side of

manifold gage and stop operation of vacuum pump.

7. The factory charge contained in the outdoor unit is good for

up to 25 ft. (8 m) of line length. For refrigerant lines longer

than 25 ft (8 m), add 0.2 oz. per foot of extra piping up to

the maximum allowable length.

8. Disconnect charge hose from charge connection of the low

side service valve.

9. Fully open service valves B and A.

10. Securely tighten caps of service valves.