F96VTN and G96VTN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

31

L09F026

L09F029

L09F028

L09F030

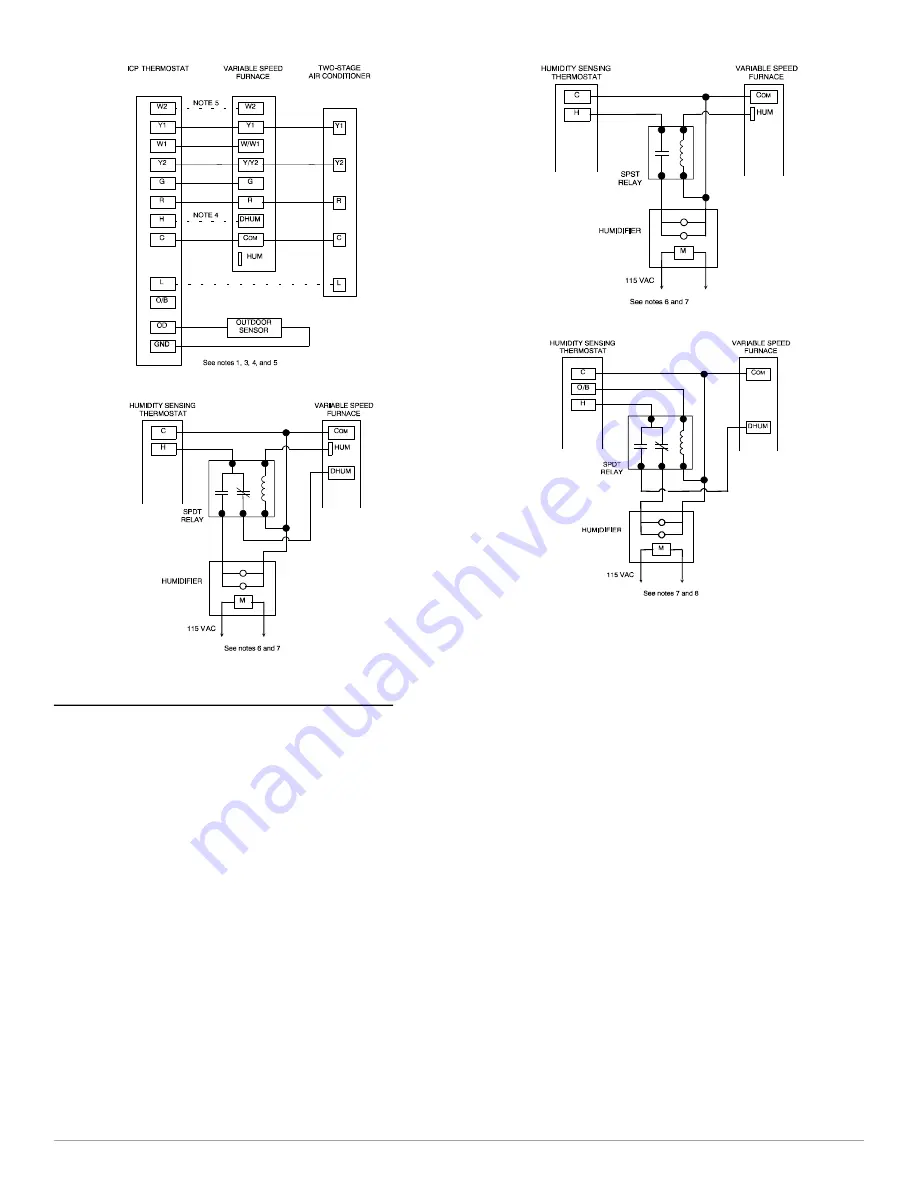

Fig. 39 – Thermostat Wiring Diagrams

NOTES FOR THERMOSTAT WIRING DIAGRAMS

1. Refer to outdoor equipment Installation Instructions for additional

information and setup procedure.

2. Outdoor Air Temperature Sensor must be attached in all dual fuel

applications.

3. Refer to ICP thermostat Installation Instructions for additional

information and setup procedure.

4. When using a Humidity Sensing Thermostat, set DEHUMIDIFY

OPTIONS to H DE-ENRGZD FOR DEHUM.

5. Optional connection. If wire is connected SW1-2 on VS furnace

control should be set in ON position to allow ICP Thermostat to

control the furnace staging.

6. HUM connection is 24 VAC and is energized when the blower turns

on during a call for heat.

7. When connecting 115 VAC to humidifier use a separate 115 VAC

supply.

8. When using a humidifier on a HP installation connect humidifier to

hot water.

9. Thermostat signals may vary. Consult thermostat installation

instructions for more information.

VENTING

NOTE:

Planning for the venting system should be done in conjunction

with planning for the ductwork, drainage, and furnace accessories, such

as air cleaners and humidifiers. Begin assembling the venting system

AFTER

the furnace is set in place in the required orientation.

Venting for this furnace shall follow all Local codes for Category IV

venting systems. This furnace is CSA approved for venting with

PVC/ABS DWV venting systems. This furnace is also CSA approved

for venting with M&G DuraVent

R

PolyPro

R

or Centrotherm InnoFlue

R

polypropylene venting systems using single wall straight and flex, and

required fittings (elbows, reducers, increasers, connectors, adapters)

only.

NOTE:

THESE INSTRUCTIONS

DO NOT

CONTAIN DETAILED

INSTALLATION INSTRUCTIONS FOR POLYPROPYLENE

VENTING SYSTEMS. Refer to the polypropylene venting system

manufacturer’s installation instructions for the polypropylene venting

system installation.

NOTE:

When using polypropylene venting systems, all venting

materials used, including the vent terminations, must be from the same

manufacturer.

Special Venting Requirements for Installations in

Canada

Installation in Canada must conform to the requirements of CSA B149

code. Vent systems

must

be composed of pipe, fittings, cements, and

primers listed to ULC S636. The special vent fittings, accessory

concentric vent termination kits (NAHA001CV or NAHA002CV) and

accessory external drain trap available from the furnace manufacturer