F96VTN and G96VTN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

19

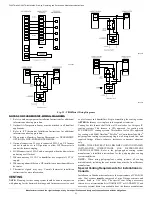

Filter Arrangement

For upflow side return applications, the Media Cabinet or field supplied

accessory air cleaner can be installed on the side of the furnace or side

and bottom when a bottom plenum is used. See

For downflow

applications, the Media Cabinet or field supplied accessory air cleaner

must only be connected to the bottom opening on the furnace. See

For horizontal applications, the Media Cabinet or field supplied

accessory air cleaner for all models can be connected to the bottom

opening on the furnace. For side return use in the horizontal position,

refer to

. If both side and bottom openings are used in

,

each opening used will require a filter.

The media cabinet or field supplied accessory air cleaner can also be

installed in the common return duct prior to entering the return air

opening in any orientation.

Refer to the instructions supplied with Media Cabinet or accessory air

filter for assembly and other details.

See

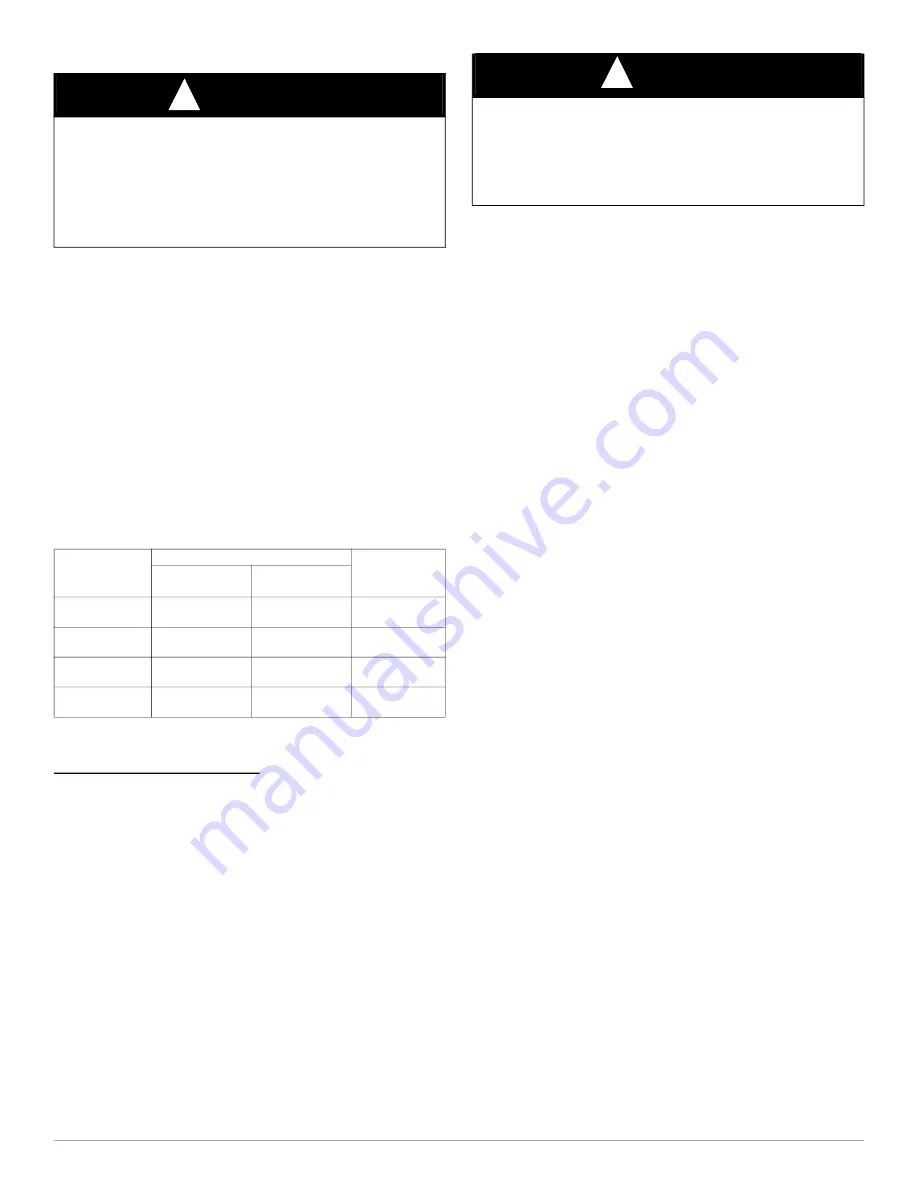

Table 6 – Air Filter Selection and Duct Sizing - In. (mm)

Filter and Return Duct Sizing

Pressure drop must be taken into account when sizing filters, filter racks,

IAQ devices, and associated system ductwork. See

comparison of Pressure Drop (initial/clean resistance to airflow) versus

Airflow for a variety of filter media types and sizes. These are

representative numbers. Consult the filter or IAQ device manufacturers’

specification sheet for performance data for a particular filter media or

IAQ device.

Design the filter and associated ductwork for the best match of pressure

drop versus filter size. Best practice usually chooses filter systems with

pressure drops under 0.2 in. W.C. (50 Pa), with the best blower electrical

efficiency and system airflow performance occurring with filter pressure

drops under 0.1 in. W.C. (25 Pa).

Provide duct transitions, as required, to smoothly transition airflow from

the return duct system to the filter (or IAQ device) to the furnace when

the dimensions of the ductwork or furnace return air opening do not

match the required filter or IAQ device dimensions. See the instructions

supplied with factory-accessory duct adapters.

WARNING

!

FIRE, CARBON MONOXIDE AND POISONING

HAZARD

Failure to follow this warning could result in fire, personal injury or

death.

Never operate a furnace without a filter or filtration device installed.

Never operate a furnace with filter or filtration device access doors

removed.

FURNACE

CASING

WIDTH

FILTER SIZE

FILTER TYPE

*

*. Recommended to maintain air filter face velocity. See Specification Sheet

for part number.

SIDE

RETURN

BOTTOM

RETURN

14-3/16 (360)

16 x 25 x 3/4

(406 x 635 x 19)

14 x 25 x 3/4

(356 x 635 x 19)

Washable

17-1/2 (445)

16 x 25 x 3/4

(406 x 635 x 19)

16 x 25 x 3/4

(406 x 635 x 19)

Washable

21 (533)

16 x 25 x 3/4

(406 x 635 x 19)

20 x 25 x 3/4

(508 x 635 x 19)

Washable

24-1/2 (622)

16 x 25 x 3/4

(406 x 635 x 19)

24 x 25 x 3/4

(610 x 635 x 19)

Washable

NOTICE

!

Design the duct system FIRST to determine how much pressure drop

may be allowed in the filter system. See the Air Ducts section.

Excessive filter pressure drop often compromises system airflow and

duct performance, causes inadequate airflow to the furthest ends of the

duct system, as well as causes excess noise and higher than anticipated

electrical consumption.