F96VTN and G96VTN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

35

Table 13 – Approved Combustion-Air and Vent Pipe, Fitting and Cement Materials

A13305

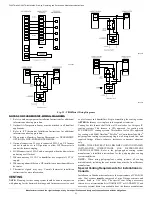

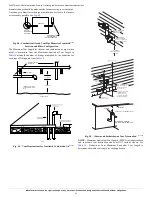

Fig. 40 – Combustion Air and Vent Pipe Termination for Direct Vent (2-Pipe) System

MATERIALS

USA

1. All pipe*, fittings*, primers**, and solvents** must conform to American National Standards Institute (ANSI) standards and

American Society for Testing and Materials (ASTM) standards

2. See Table below for approved materials for use in the U.S.A.

3. UL 1738 vent systems must be composed of pipe*, fittings**, cements, and primers** from the same supplier.

CANADA

1. Installation in Canada must conform to the requirements of CAN/CSA B149 code.

2. Vent systems must be composed of pipe*, fittings*, cements, and primers from the same supplier and listed to ULC S636.

3. Not all materials below may be approved or listed to ULC S636.

4. Factory accessory concentric vent kits are ULC S636 listed.

Material

Description

Type

ASTM / ULC / UL Specification

Pipe*

Fittings*

Solvents/Primers**

Cements

PVC

Pressure Pipe

Schedule 40

D1785 / UL 1738

D2466 or D2665

F656

D2564

DWV

Schedule 40

D1785 / D2665

SDR 26

N/A

D2241

SDR 21

N/A

D2241

IPEX

Schedule 40

ULC S636

ULC S636

ULC S636

ULC S636

Royal Pipe

Schedule 40

ULC S636

ULC S636

ULC S636

ULC S636

ABS

ABS

Schedule 40

D2661

D2468

Clear Cleaner For

ABS†

D2235

DWV-IPS Sizes

Schedule 40

D2661

D2661

CPVC

Pressure Pipe

Schedule 40

F441

F438

F656

F493

SDR

N/A

F442

N/A

IPEX

Schedule 40

ULC S636

ULC S636

ULC S636

ULC S636

Royal Pipe

Schedule 40

ULC S636

ULC S636

ULC S636

ULC S636

* PVC and ABS pipe may use either DWV or pressure rated fittings.

** Colored or tinted solvents or primers must be used where required by code in the USA

† ABS plastic does not require a primer before solvent cementing. A cleaner for ABS is recommended to remove any surface residue. ABS cleaners are

not subject to ASTM standards.

Polypropylene

Approved Manufacturer

Solvents Primers

Cements

Poly

Pro®

M & G Dura Vent

Not Permitted

Innoflue

®

Centrotherm

Not Permitted

ECCO

Polypropylene

Vent®

ECCO Manufacturing

Not Permitted

NOTE: Polypropylene vent systems are UL

−

1738 and ULC S636 listed and assembled using mechanical fastening systems supplied by the vent

manufacturer.

LQPPIRULQPP

12 in. (305mm) min. separation

between bottom of combustion

air and bottom of vent (Typ.)

LQPPIRULQPP