K90-KPCS-IM-2

18/04/22

- 7 -

Refrigerant

Liquid Line Rise in Feet

10'

15'

20'

25'

30'

PSIG

°F

PSIG

°F

PSIG

°F

PSIG

°F

PSIG

°F

R134a

4.9

2.0

7.4

2.9

9.8

4.1

12.3

5.2

14.7

6.3

R22

4.8

1.6

7.3

2.3

9.7

3.1

12.1

3.8

14.5

4.7

R404A

R507

4.1

1.1

6.1

1.6

8.2

2.1

10.2

2.7

12.2

3.3

R407A

R407A

R407C

R448A

R448A

R449A

R449A

4.3

1.4

6.5

2.1

8.7

2.8

10.8

3.5

12.8

4.1

Refrigerant

Liquid Line Rise in Feet

40'

50'

75'

100'

PSIG

°F

PSIG

°F

PSIG

°F

PSIG

°F

R134a

19.7

8.8

24.6

11.0

36.8

17.0

49.1

23.7

R22

19.4

6.2

24.2

8.0

36.3

12.1

48.4

16.5

R404A

R507

16.3

14.1

20.4

5.6

30.6

8.3

40.8

11.8

R407A

R407A

R407C

R448A

R448A

R449A

R449A

17.82

5.5

21.82

7

32.82

11

43.82

14

Based on 110°F liquid temperature at bottom of riser.

Pressure Loss of Liquid Refrigerant in Liquid Line Risers

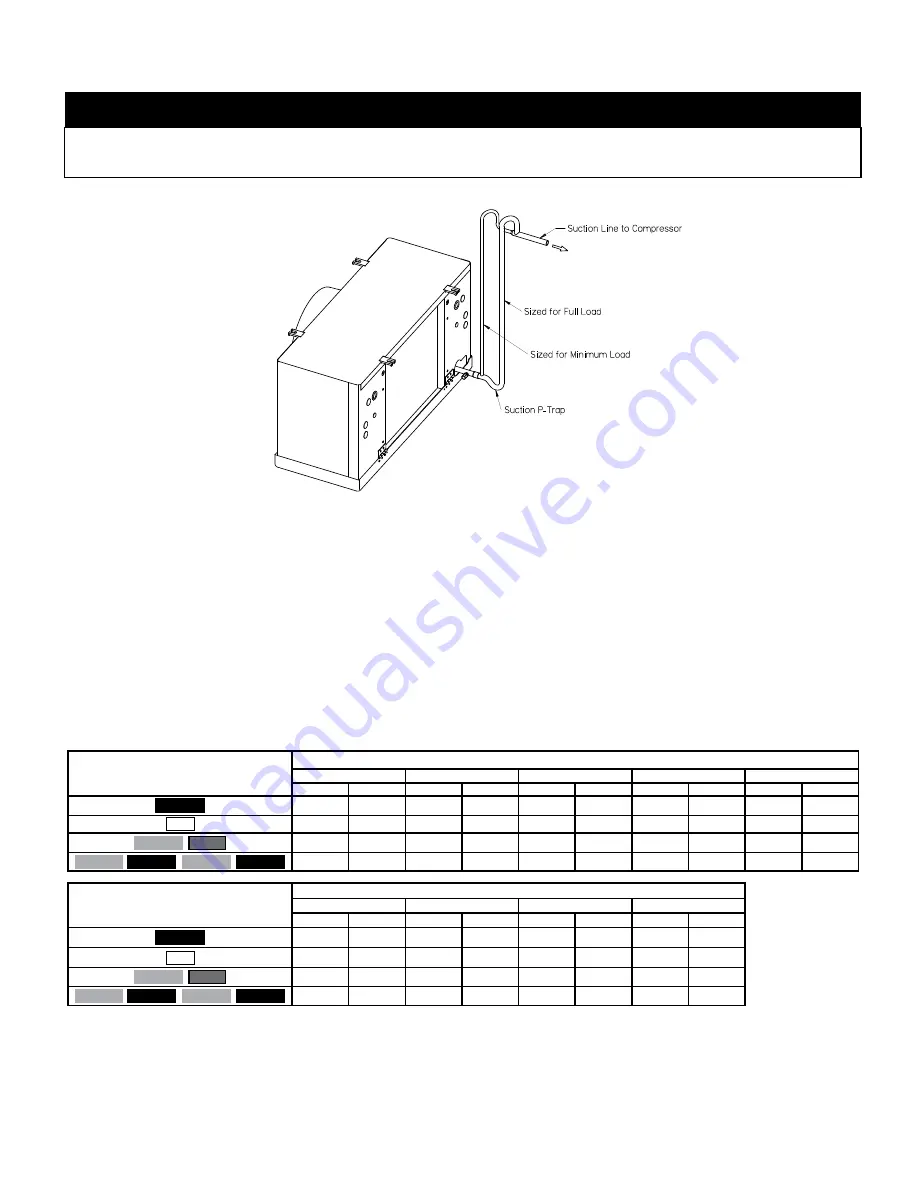

If steps of capacity control are supplied on a compressor, provisions must be made for oil return by sizing suction risers to maintain

adequate gas velocities at reduced refrigerant flow.

IMPORTANT PIPING NOTE

REFRIGERANT PIPING (cont’d)

IMPORTANT:

All suction lines outside of the refrigerated space

must be insulated.

During the lower capacity running mode (compressor capacity

control energized) oil will collect in the elbow or at U-bend below

pipe “B”. This will divert the gas and oil to flow up the smaller pipe

“A” at a higher velocity.

Liquid Line

: Horizontal liquid lines should be sized on a basis of

a maximum pressure drop equivalent to a 2°F

(1.1°C)

drop in the

sub-cooling temperature. If the lines must travel up vertically then

adequate sub-cooling must be provided to overcome the vertical

liquid head pressures. A head of two feet of liquid refrigerant is

approximately equivalent to 1 psig

(6.9 kPa)

. Liquid line velocities

should not exceed 300 fpm

(1.52 m/s)

. This will prevent possible

liquid hammering when the solenoid valve closes

IMPORTANT:

When brazing service valves or any components that may be damaged by heat, manufacturer’s installation instructions

must be followed. Wrapping components with a wet cloth will help to prevent damage from heat.