INSTALLATION INSTRUCTIONS

R−410A, Two−Stage Split System Air Conditioner

421 01 6002 01

11

COMPRESSOR OPERATION

The basic scroll design has been modified with the

addition of an internal unloading mechanism that opens

a by−pass port in the first compression pocket, effectively

reducing the displacement of the scroll. The opening and

closing of the by−pass port is controlled by an internal

electrically operated solenoid. The modulated scroll uses

a single step of unloading to go from full capacity to

approximately 67% capacity.

A single speed, high efficiency motor continues to run

while the scroll modulates between the two capacity

steps. Modulation is achieved by venting a portion of the

gas in the first suction pocket back to the low side of the

compressor, thereby reducing the effective displacement

of the compressor.

Full capacity is achieved by blocking these vents, thus

increasing the displacement to 100%. A DC solenoid in

the compressor, controlled by a rectified external 24 volt

AC signal, moves the slider ring that covers and uncovers

these vents.

The vent covers are arranged in such a manner that the

compressor operates at approximately 67% capacity

when the solenoid is not energized and 100% capacity

when the solenoid is energized. The loading and

unloading of the two step scroll is done “on the fly” without

shutting off the motor between steps.

NOTE: 67% compressor capacity translates to

approximately 80% cooling or heating capacity at the

indoor coil.

The compressor will always start unloaded and stay

unloaded for five seconds even when the second stage

of the thermostat is calling for more capacity (a starting

advantage under low voltage conditions).

TROUBLESHOOTING

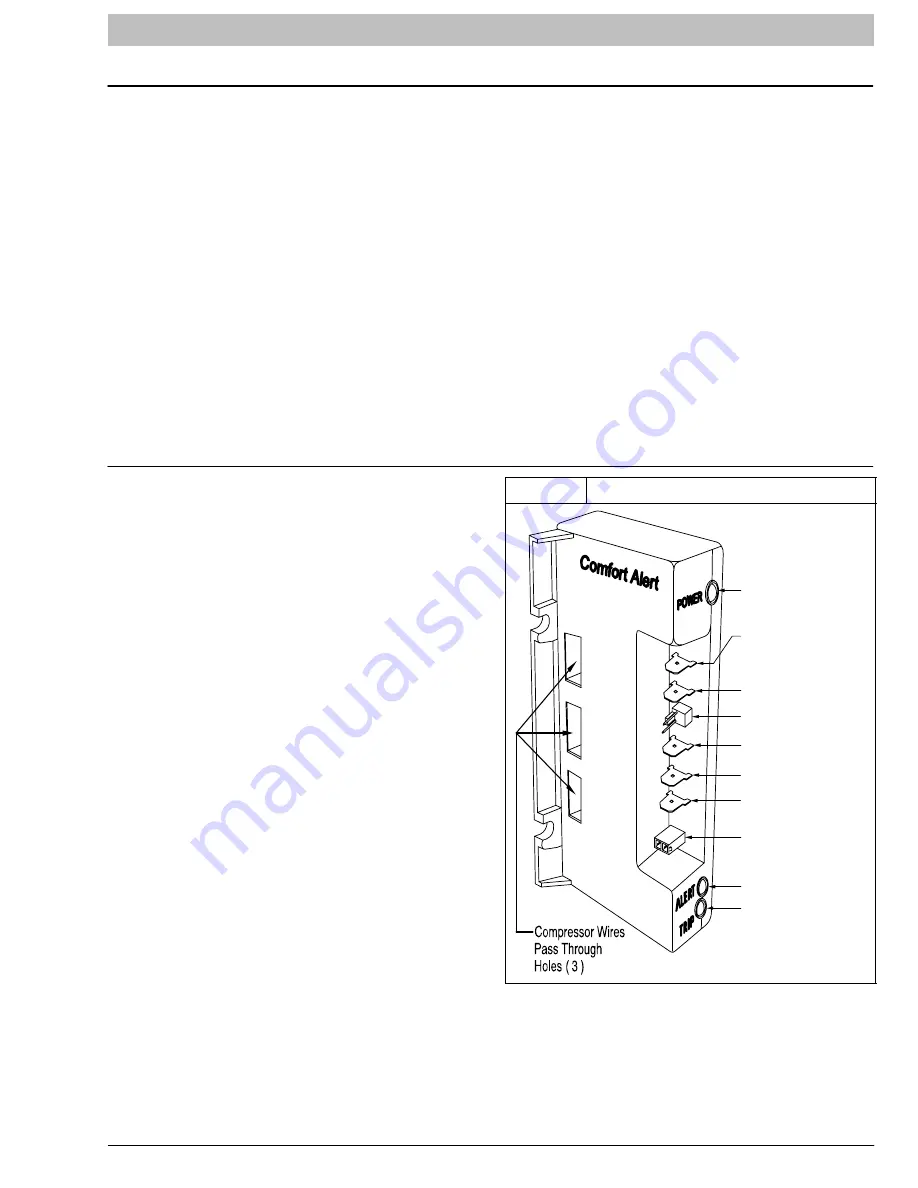

Models are factory equipped with the Comfort Alert

UltraTech

Diagnostics device (refer to Figure 12) in the

control box. Comfort Alert UltraTech

provides

compressor staging from low to high and high to low

capacity. Comfort Alert UltraTech provides

around−the−clock monitoring for common electrical

problems, compressor defects, and broad system faults.

If trouble is detected, an alert code is displayed with a

flashing LED indicator. Alert codes are listed in Figure 13.

The device is factory wired and requires no

modification. Low voltage lead wires are provided in the

control box for connection to thermostat wires (use wire

nuts).

The Comfort Alert UltraTech must be powered to properly

stage compressor to high capacity. Energizing the Y (Y1)

terminal operates the compressor in low−stage. Both the

Y (Y1) and Y2 terminals must be energized for

high−stage operation.

The Comfort Alert UltraTech device operates by

monitoring the compressor power leads and the

thermostat demand signals Y (Y1) and Y2 terminals. It

draws constant 24 VAC power at the R and C terminals.

When the compressor is operating in low−stage (Y or Y1),

the 24v DC compressor solenoid coil is de−energized.

When the compressor is operating in high−stage (Y or Y1

and Y2), the 24v DC solenoid coil is energized. The 24v

DC plug that is connected to the compressor does NOT

have an internal rectifier. DO NOT INSTALL A PLUG

WITH INTERNAL RECTIFIER.

Figure 12 Comfort Alert

t

UltraTech

t

Diagnostics

Y2

Y

L

R

C

R

C

S

“Power” LED

Thermostat Demand

1

st

Stage Compressor

Data Port

Thermostat Signal

24 VAC HOT

24 VAC Common

DC Compressor

Solenoid

“Alert” LED

“Trip” LED

Thermostat Demand

2

nd

Stage Compressor