INSTALLATION INSTRUCTIONS

R−410A, Two−Stage Split System Air Conditioner

421 01 6002 01

13

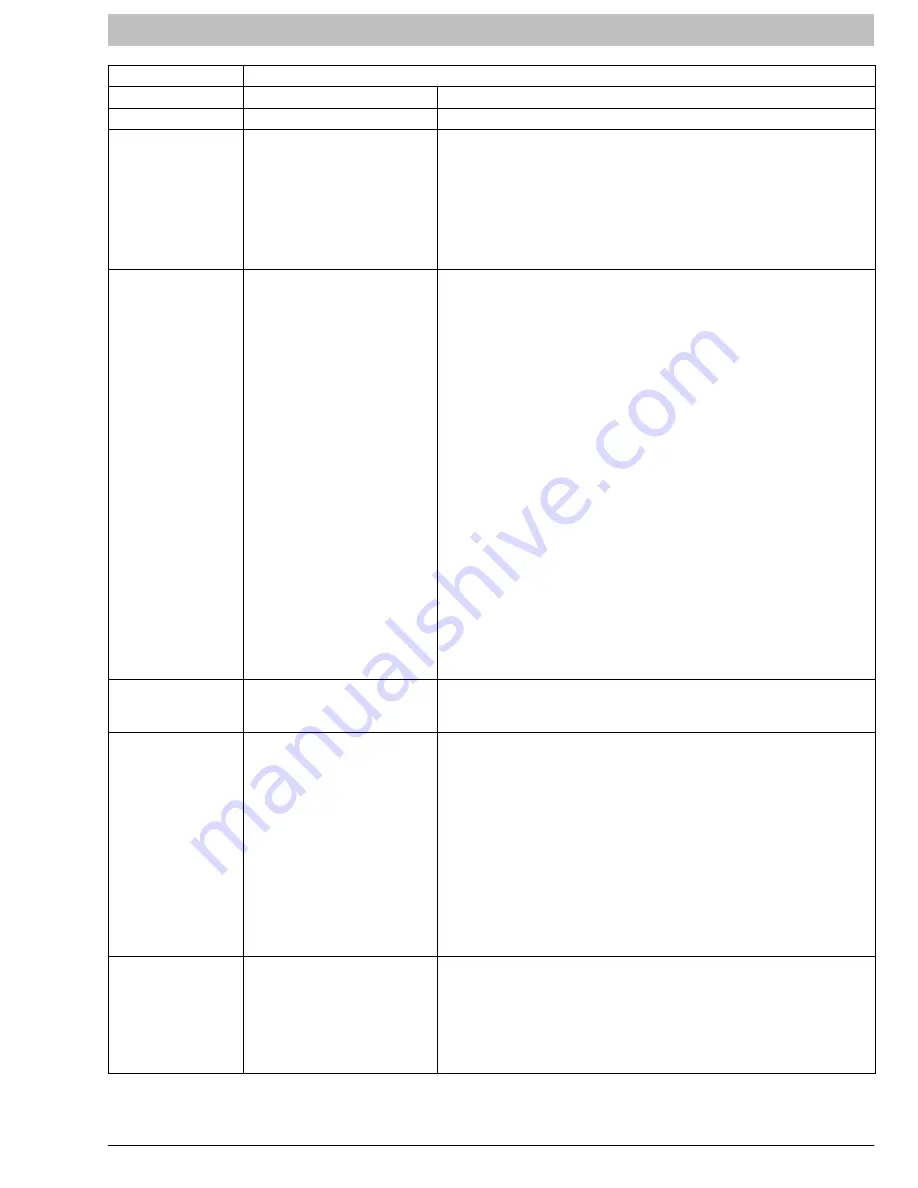

Figure 13

Comfort Alert

t

UltraTech

t

Diagnostics

Status LED

Status LED Description

Status LED Troubleshooting Information

Green “POWER”

Module has power

Supply voltage is present at module terminals

Red “TRIP”

Thermostat demand signal

Y is present, but the

compressor is not running

1. Compressor protector is open

•

Check for high head pressure

•

Check compressor supply voltage

2. Outdoor unit power disconnect is open

3. Compressor circuit breaker or fuse(s) is open

4. Broken wire or connector is not making contact

5. Compressor contactor has failed open

Yellow “ALERT”

Flash Code 1

Long Run Time

Compressor is running

extremely long run cycles

(18 hours or more)

1. Low refrigerant charge

2. Evaporator blower is not running

•

Check blower relay coil and contacts

•

Check blower motor for failure or blockage

•

Check evaporator blower wiring and connectors

•

Check indoor blower control board

•

Check thermostat wiring for open circuit

3. Evaporator coil is frozen

•

Check for low suction pressure

•

Check for excessively low thermostat setting

•

Check evaporator airflow (coil blockages or return air filter)

•

Check ductwork or registers for blockage

4. Faulty metering device

•

Check TXV bulb installation (size, location, and contact)

•

Check if TXV is stuck closed or defective

5. Condenser coil is dirty

6. Liquid line restriction (filter drier blocked)

7. Compressor high−stage cooling wiring

•

Solenoid plug not connected / malfunction

•

Comfort Alert

failure

8. Thermostat is malfunctioning

•

Check thermostat sub−base or wiring for short circuit

•

Check thermostat installation (location, level)

Yellow “ALERT”

Flash Code 2

Internal Protector Trip

1. The internal motor protector has opened

•

Wait for compressor to cool down, protector will close

automatically

Yellow “ALERT”

Flash Code 3

Short Cycling

Compressor is running only

briefly (1−3 minutes)

1. Thermostat demand signal is intermittent

2. High head pressure

•

Check high pressure switch

•

Check if system is overcharged with refrigerant

•

Check for non−condensable in system

3. Condenser coil poor air circulation (dirty, blocked, damaged)

4. Condenser fan is not running

•

Check fan capacitor

•

Check fan wiring and connectors

•

Check fan motor for failure or blockage

5. Return air duct has substantial leakage

6. Low pressure switch open, see Flash Code 1 information

Yellow “ALERT”

Flash Code 4

Locked Rotor

1. Run capacitor has failed

2. Low line voltage (contact utility if voltage at disconnect is low,

below 187v)

•

Check wiring connections

3. Excessive liquid refrigerant in compressor

4. Compressor bearings are seized

− continued on next page −