2

2

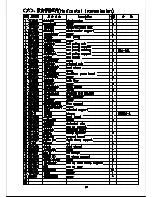

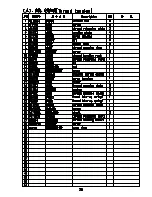

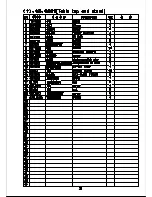

Function And Description

Setting Range

Unit

Remarks

P-1

x origin

-500000------500000

P-2

y origin

-500000------500000

P-3

thread trim open angle

0------355

P-4

thread release dev angle

160------320

P-5

Clamping solenoids PWM

10------1000

P-6

presser plate 1 solenoids pwm

10------1000

P-7

presser foot solenoids pwm

10------1000

P-8

presser plate 2 solenoids pwm

10------1000

P-9

x sensor polarity

0invariant---1negation

P-10

y sensor polarity

0invariant---1negation

P-11

y drive mode

50---250

P-12

clamping open angle

0-----170

P-13

needle stop position check

-300-----300

P-14

count of pressure box signal

0-----4

P-15

limiting speed

400-----2700

P-16

Thread loose open time

1-----180

P-17

pressurebox width check(mm)

-300-----300

P-18

presser foot up time

50-----2000

P-19

main shaft start time

40-----1000

P-20

presserfoot max height

30-----200

mm

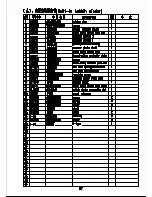

P-21

z sensor polarity

0invariant---1negation

P-22

foot motor rotation direction

0invariant---1negation

P-23

pressure plate1 nature state

0down---1up

P-24

pressure plate2 nature state

0down---1up

P-25

pressure plate2 function

0---3

P-26

X sewing range

500-12000

mm

P-27

Y sewing range

400-10000

mm

P-28

clamp close angle

1-350

P-29

sweep thread

0clamp---1choose

P-30

u origin

-800---800

P-31

v origin

-800---800

P-32

clamping cylinder status

0close---1open

P-33

Foot Max Dynamic Height

50---120

P-34

thread trim solenoids pwm

10---1000

P-35

thread loose solenoids pwm

10---1000

P-36

oil motor work time

1---60

P-37

oil motor stop time

1---60

Summary of Contents for GA204-107

Page 1: ...BT 11020 RP TB PARTS INSTRUCTION MANUAL...

Page 8: ...00 1 2 3 4 5 2 50 054 5 652257 5 58 9 5 4 4 57 22 4 5 3 257...

Page 9: ......

Page 10: ...0 1 2 3 4 2 3 4 3 5 6 503 7 3 4 8 3 9 9 2 5 5 0 0 5 0 5 5 3...

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......