72

attached to it.

Check conduction between the surfaces of other components.

Ensure non-conduction between armature shafts of the commutator.

Check the conduction of the shell of the startup motor.

Ensure non-conduction between the conduction terminal and the startup motor shell.

Check conduction between the conduction terminal and the brush.

Replace any abnormal part.

Check conduction of the brush bracket. Replace it when there is conduction.

Measure the length of the brush.

Limit for use: replace it if lower than 3mm

Check smooth rotation of the needle bearing inside the front cover and whether it is loose when press-in.

Replace it if there is any abnormality.

Check whether the oil seal is abraded or damaged.

3.3.4 Assembly

Lubricate the oil seal inside the front cover with grease.

Install the brush on the bracket.

Lubricate moving parts at two ends of the brush shaft

with grease.

Press each brush into the bracket and install the electrode

front cover.

* Note

• Pay special attention that the contact surface between the

brush and the armature shall not be damaged.

• Pay attention that the armature shaft shall not damage lips

of the oil seal.

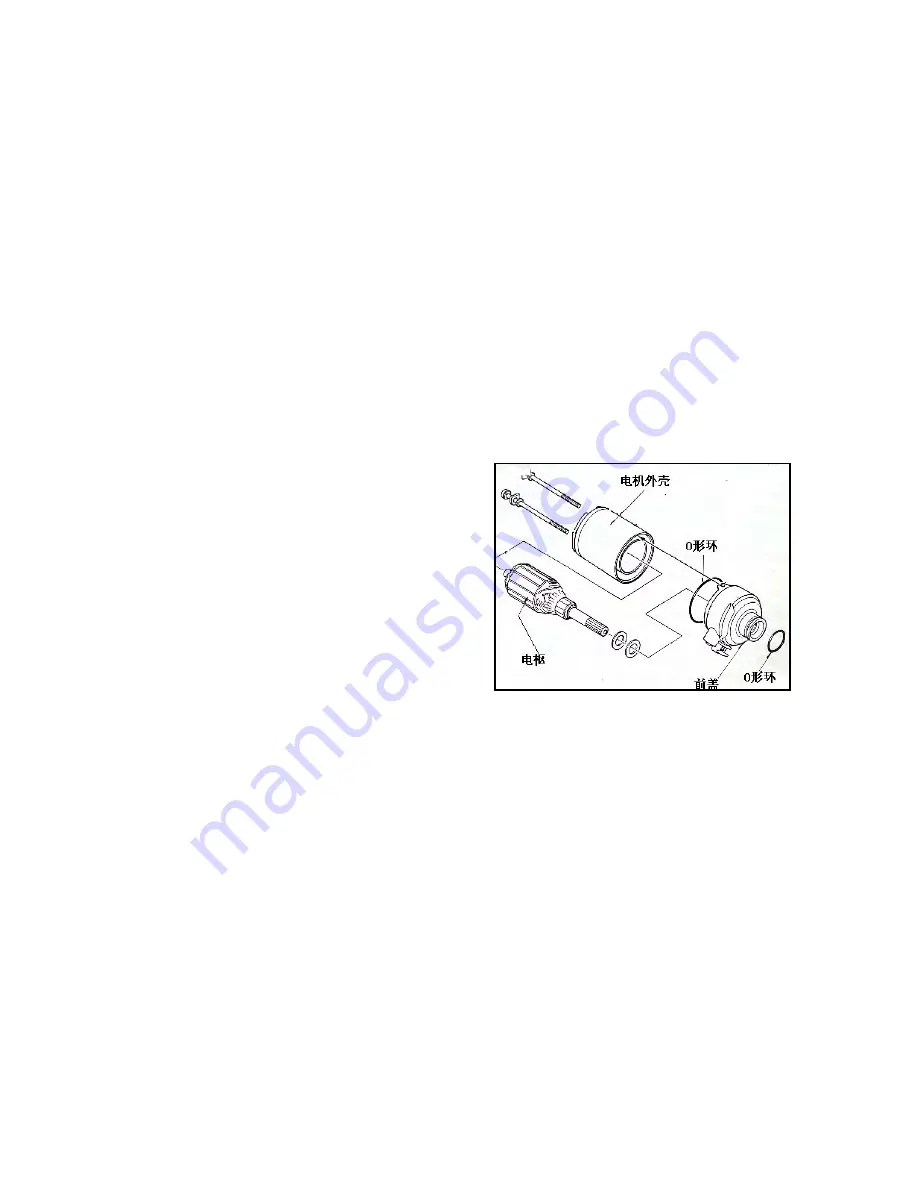

Install the new o-ring into the front cover.

(

o

型环:

o-ring

电机外壳:

motor shell

Aim the screw hole of the motor shell at the screw hole of

电枢:

armature

前盖:

front cover)

the front cover for installation.

Lock screws in the shell.

* Note

When the shell and the front cover are assembled, it is easy

to pull the front cover with magnet to attract the armature.

Press it gently for assembly

3.3.5 Installation

Install the lead of the startup motor and the dustproof boot.

Replace any damaged or abnormal o-ring.

Lubricate o-ring with fuel and then install it on the startup motor.

Install the wire clip for rear brake.