9

3.3

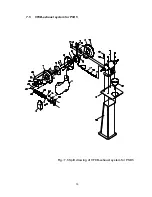

Maintenance of belt arm

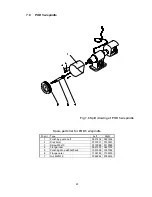

Empty the spark arrester (A) (see

fig.: 3.3

) to avoid hot sparks damaging or

deforming grinding belt and contact wheel. If the machine is equipped with VFCB-

exhaust unit you must control if the suction channels need cleaning. The dust bag

must be emptied when necessary. The contact wheel (B) needs changing if the

edges are too rounded. The belt must be replaced when it is defective. Change the

graphite pad (C) on the belt arm when necessary.

Fig.: 3.3

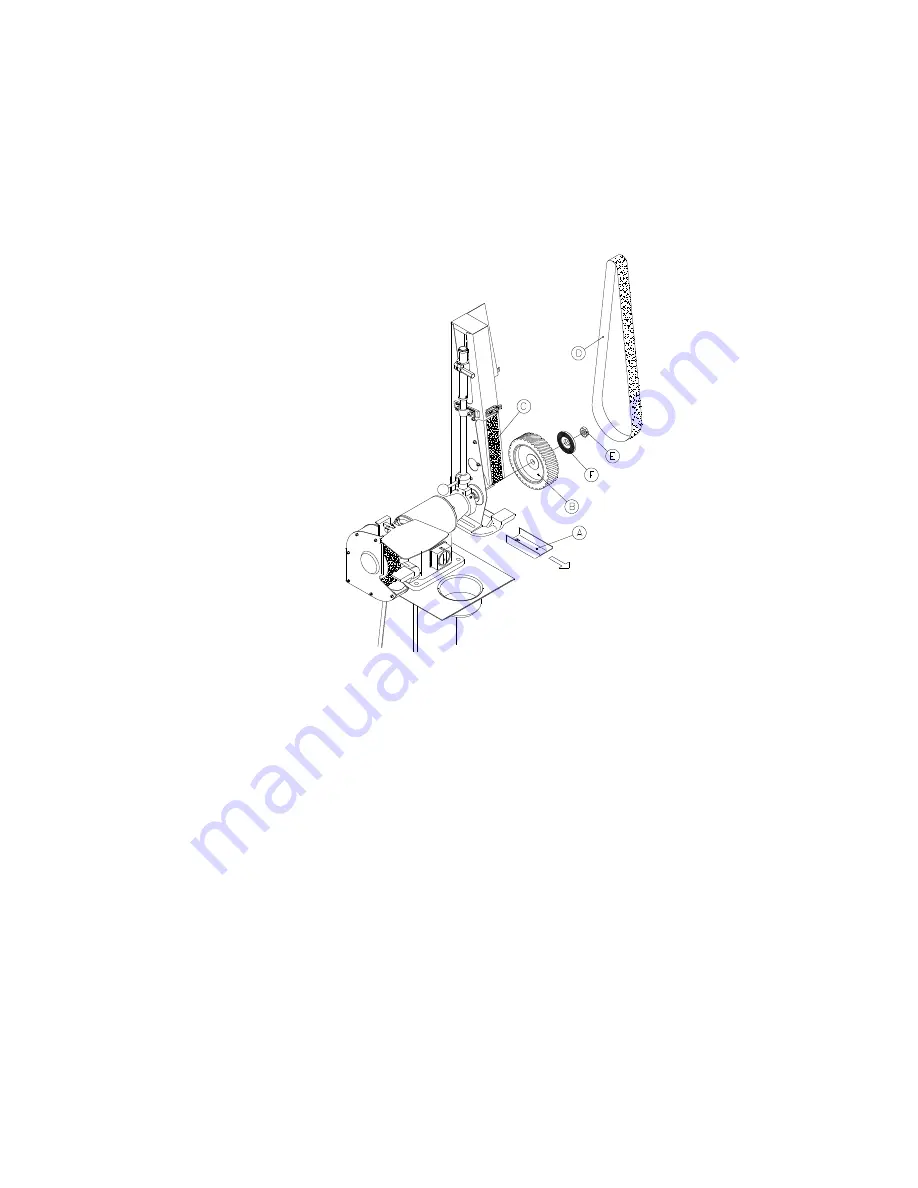

When changing the contact wheel the grinding belt (D) must be dismounted as

described above. The reverse nut (E) must be dismounted and the flange (F) can

be taken off with the contact wheel (B). The new contact wheel (B) is to be mounted

in reverse order.

3.4

Use of belt arm

Grinding at the belt arm can be done either at the contact wheel or on the grinding

surface. You can also dismount the grinding surface for direct unsupported grinding

on the grinding belt. Let the material touch the grinding belt softly and avoid uneven

grinding as it can damage the grinding belt and overload the motor.