53

Tank Selection

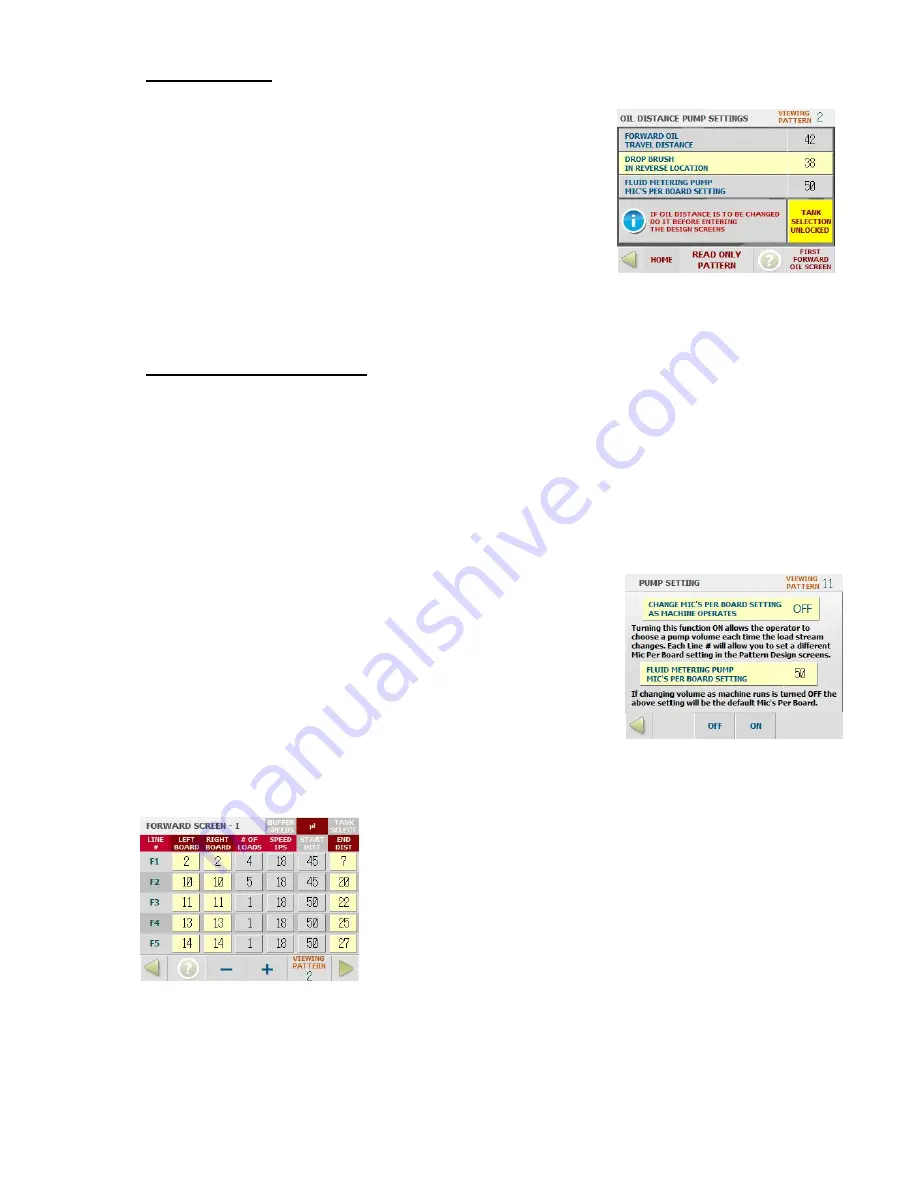

This new feature will allow the pattern designer to blend two

compatible lane conditioners on each of the program lines in

the forward or reverse screens.

By pressing the TANK SELECTION LOCKED button, the screen

will be highlighted in yellow and changed to UNLOCKED. You

will now be able to choose either Tank A, Tank B or both

within each program line. This will be explained later in this

chapter.

Adjustable Pump Volume

The purpose of this feature is to give the programmer the added FLEX ability when fine

tuning your oil pattern. You can run one volume setting on your first load line to control the

amount of oil distributed on the outside, while giving you the ability to increase the volume

in the center of the pattern for increased hold area. It can also be useful when more or less

volume is needed in a given part of the line without compromising another part of the oil

pattern.

From the OIL DISTANCE PUMP settings screen, press on the

FLUID METERING PUMP MICS PER BOARD and the screen to

the right will appear. By pressing the OFF button, the screen

will change to ON allowing the operator to adjust the volume

output on each of the oil lines within the programming

screen. If no adjustment is made, the default value will be

50µl.

Press the button labeled µl located above the START DIST

button and the values for the µl for each of the program lines

appear in place of the START DISTANCE values.

After doing this, you will have enabled the Mics per board

setting and will be able to change the Volume Output on each

of the LOAD LINES within each of the screens.

Summary of Contents for FLEX 17-5801

Page 1: ...OPERATORS MANUAL Edition 03 18...

Page 2: ......

Page 12: ......

Page 16: ...4 Wah lah I did them the same...

Page 51: ...39...

Page 171: ...159...

Page 172: ...160 CHAPTER 7 Miscellaneous Parts Stickers and Decals...

Page 173: ...161...

Page 174: ...162...

Page 176: ...164...

Page 178: ......

Page 181: ......

Page 183: ......

Page 185: ......

Page 187: ...7 7...

Page 189: ......

Page 191: ......

Page 193: ......

Page 195: ......

Page 197: ......

Page 199: ...14 15 16 17 18 19 5 4 7 6 13 8 9 10 2 12 11 9 3 8 10 9 1 3 9 10 12...

Page 201: ......

Page 203: ......

Page 205: ...7 7...

Page 207: ......

Page 209: ......

Page 211: ......

Page 213: ......

Page 215: ...7 5 7...

Page 217: ......

Page 219: ......

Page 221: ......

Page 223: ......

Page 225: ......

Page 227: ...7 7...

Page 229: ......

Page 231: ......

Page 233: ...7...

Page 235: ......

Page 237: ......

Page 239: ...3 2 9...

Page 241: ......

Page 243: ......

Page 245: ......

Page 246: ...235...

Page 248: ...230...

Page 249: ...231...

Page 250: ...232...

Page 251: ...233...

Page 252: ...234...

Page 253: ...235...

Page 254: ...236...

Page 255: ...237...

Page 256: ...238...

Page 257: ...239...

Page 258: ...240...

Page 259: ...241...

Page 260: ...242...

Page 261: ...243...

Page 262: ...244...

Page 263: ...245...

Page 264: ...246...

Page 265: ...247...

Page 266: ...248...

Page 267: ...249...

Page 268: ...250...

Page 269: ...251...

Page 270: ...252...

Page 271: ...253...

Page 272: ...254...

Page 273: ...255...

Page 274: ...261...

Page 276: ...257...

Page 277: ...258...

Page 278: ...259...

Page 279: ...260...

Page 280: ...261...

Page 281: ...262...

Page 282: ...263...

Page 283: ...264...

Page 284: ...265...

Page 285: ...266...

Page 286: ...267...

Page 287: ...268...

Page 288: ...269...

Page 289: ...270...

Page 290: ...271...

Page 291: ...272...

Page 292: ...273...

Page 293: ...274...

Page 294: ...275...

Page 295: ...276...

Page 296: ...277...

Page 297: ...278...

Page 298: ...279...

Page 299: ...280...

Page 300: ...281...

Page 301: ...282...

Page 302: ...283...

Page 303: ...290...