Power Conversion System BCS-B-H Series (1000K-1500K)

User Manual

6 Routine Maintenance

All rights reserved © Kehua Data Co., Ltd.

67

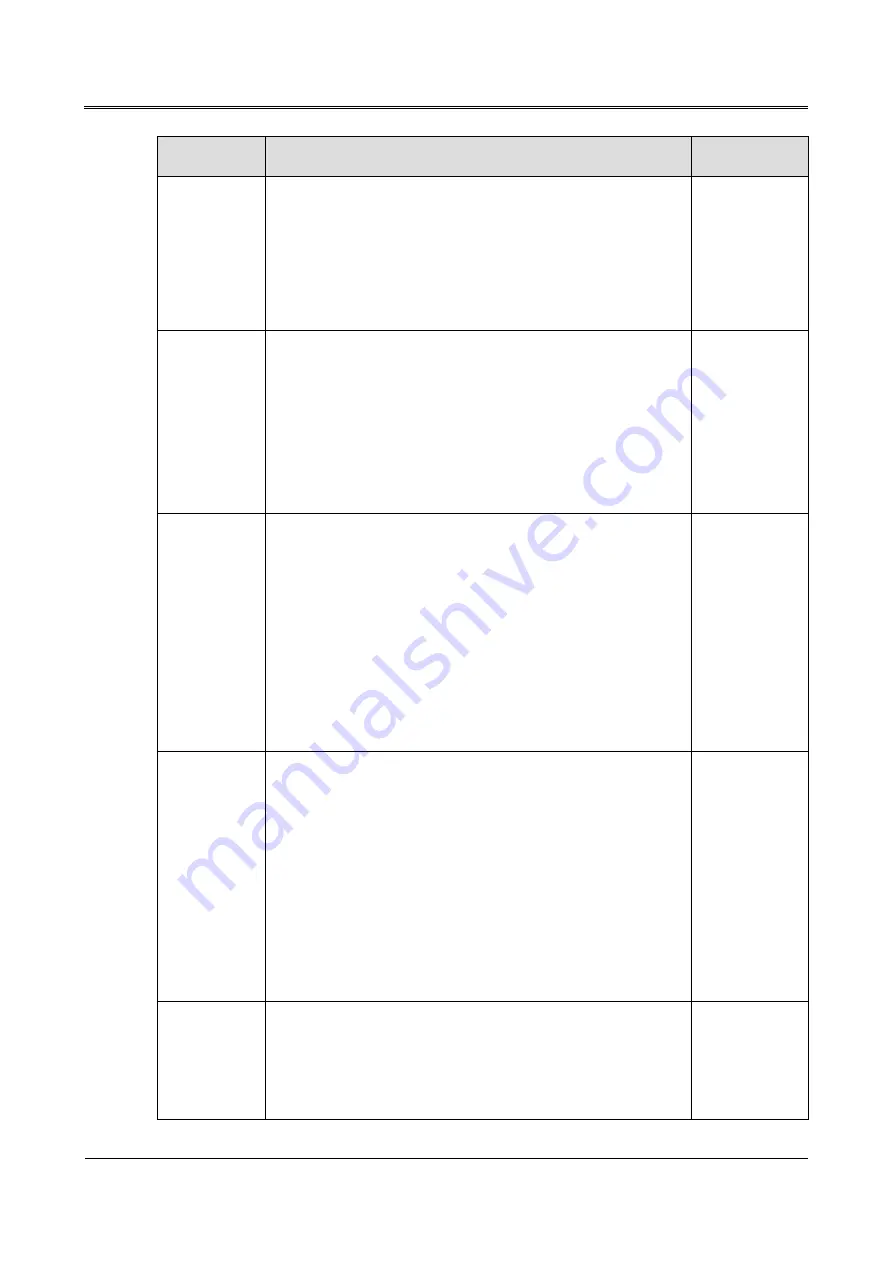

Item

Check method

Period

9.

Check the filter screen behind the air inlet and see if it's

function is normal.

Note: the air inlet holes must be checked. Or, once the holes

blocked, the PCS will not be cooled effectively, even

over-temperature and fault.

System

cleanness

1.

Check the cleanness of PCB and each component.

2.

Check the temperature of heat sink and the dust surrounding,

if necessary, clean the heat sink by dust collector to avoid

influence the normal work of the heat sink.

3.

Replace the filter screen.

Every

three

months/

half

year/ one year

on the basis of

the

use

environment.

The

connection of

power circuit

1.

Check if the power cables are loose, fasten them according to

the torque mention in

2.

Check if there is damage on the power cables and control

wires, especially the surface touching with metal, if damaged,

please maintain it in time.

3.

Check if the insulation tape on power cables comes off. If

yes, please bind up the insulation tape in time.

Maintain

it

after

first

commissioning,

and

then

maintain

it

every half to

one year.

The

connection of

terminal and

copper bars

1.

Check if the terminals on main circuit (such as: wiring

terminals of input and output wires in primary side) is

connected in good condition, the bolts is not over-heating.

2.

Check the screws of control terminals and see if they are

loosen, if yes, fasten then by screwdriver.

3.

Check if the color of the cooper bars and screws is changed.

4.

Check terminal the connection and wiring layout of the PCS.

Every

three

month

Maintenance

and

replacement

for

cooling

1.

Check if the blade of fan has crack.

2.

Check if the fan work normally and if there is any sundries

blocked the air outlet holes.

Every

three

month

Summary of Contents for BCS-B-H Series

Page 1: ...Power Conversion System BCS B H Series 1000K 1500K User Manual...

Page 2: ......

Page 96: ...4402 02858 005...