Gewicht

MKS_DSV6100

36

2

Nylon - 6/6

servohebel

37

2

Pappelsperrholz

Anschlussrippe

H1

H1

2

Balsaholz

Rippe

H2

H2

2

Balsaholz

Rippe

H3

H3

2

Balsaholz

Rippe

H4

H4

2

Balsaholz

Rippe

H5

H5

2

Balsaholz

Rippe

H6

H6

2

Balsaholz

Rippe

H7

H7

2

Balsaholz

Rippe

H8

H8

2

Balsaholz

Nasenleiste

H9

H9

2

Kiefer

Holm

H10

H10

2

Balsaholz

Abdeckung Mitte

H11

H11

1

Balsaholz

Abdeckung oben

H12

H12

1

Balsaholz

Abdeckung unten

H13

H13

1

Balsaholz

Nasenleiste Mittelteil

H14

H14

1

Balsaholz leicht

Beplankung unten

H15unten

H15

1

Balsaholz leicht

Beplankung H hensteuer

H15

H15

1

Balsaholz

Mittelrippe Mittelteil

H16

H16

2

Pappelsperrholz

Frontspant Mittelteil

H17

H17

1

Pappelsperrholz

Mittelspant Mittelteil

H18

H18

1

Pappelsperrholz

Zentralrippe

H19

H19

1

Pappelsperrholz

Mittelsteg Mittelteil

H20

H20

1

Sperrholz

Anschlussrippe Mittelteil

H21

H21

1

Balsaholz

Spant hinten Mittelteil

H22

H22

1

Balsaholz

Beplankung unten Mittelteil

H23

H23

1

Balsaholz

Ruderholm vorne

H24

H24

1

Balsaholz

Ruderholm hinten

H25

H25

1

Sperrholz

Servorahmen

H26

H26

2

Balsaholz

Rippe hinten unten Mittelteil

H27

H27

2

Balsaholz

Rippe oben Mittelteil

H28

H28

1

Balsaholz

Randbogen

H29_MIR_MIR

H29

1

Balsaholz

Randbogen

H29_MIR1

H29

1

Balsaholz

Randbogen

H29_MIR

H29

1

Balsaholz

Randbogen

H29

H29

1

Sperrholz

Randbogen Mitte

H30

H30

1

Sperrholz

Randbogen Mitte

H30_MIR

H30

1

Sperrholz

Servodeckel

H31

H31

2

Aluminium - 6061

Steckungsrohr HLW

H32

1

Aluminium - 6061

Fuehrungshuelse_HL

W

H33

1

Aluminium - 6061

Schraubenhuelse_HL

W

H34

1

Balsaholz

Beplankung Mittelteil

Podbeplankung

H35

1

Edelstahl, 440C

Zylinderkopfschrauben mit Schlitz -

Produktklasse A

ISO 1207 - M5 x 50

H36

1

Balsaholz

F llst ck

H37_MIR

H37

1

Balsaholz

F llst ck

H37

H37

1

Phenolharz

Ruderhorn H hensteuer

H38

H38

2

Holz (Eiche)

Zentrierd bel

H39

H39

1

Material / Behandlung

BESCHREIBUNG

Gegenstand

Pos.

Anz

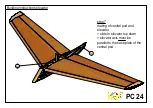

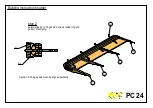

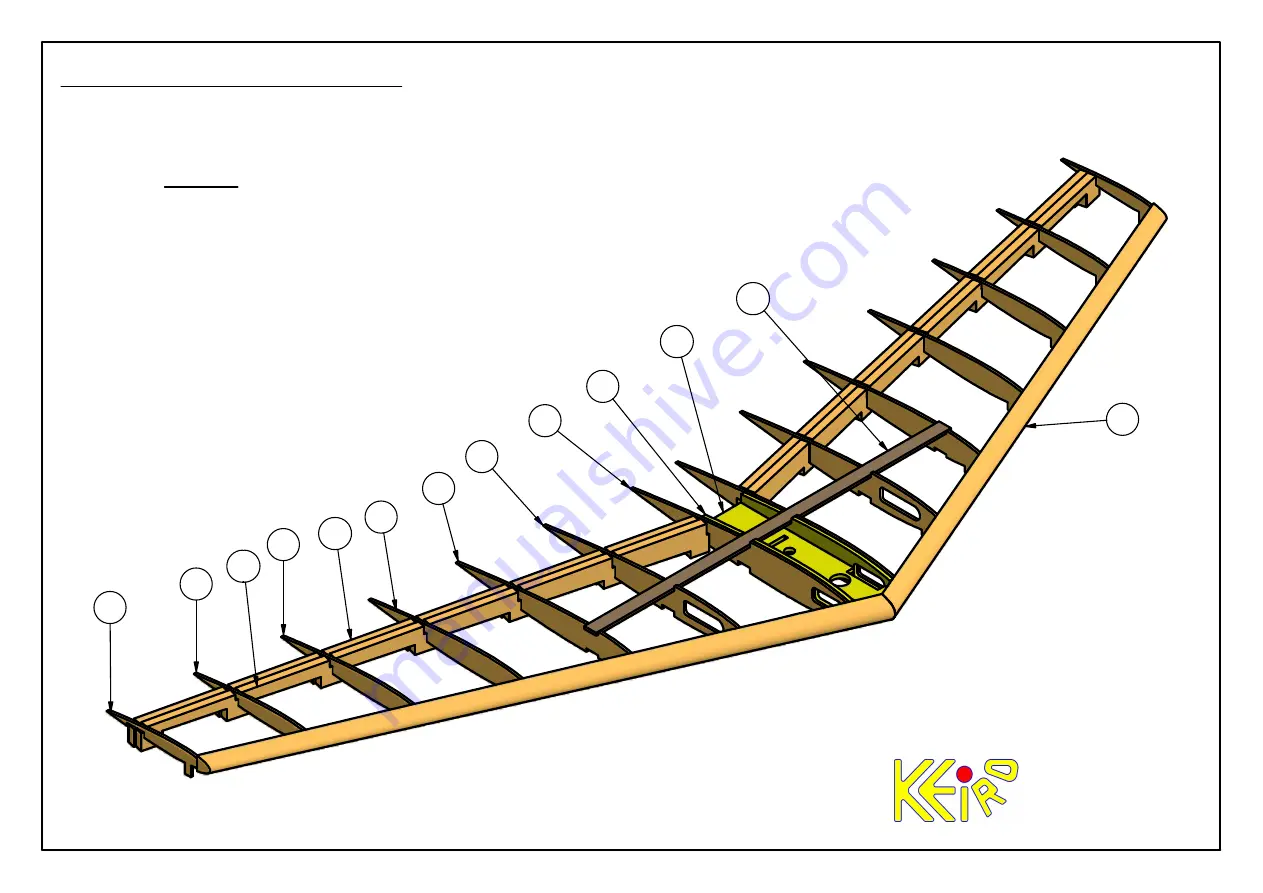

step 1

rib frame

assemblage on the plan-sheet

CAUTION: don't glue together H24 and H25

That's the hinge line.

PC 24

H8

H7

H6

H5

H4

H3

H2

H25

H24

H1

H19

H10

H9

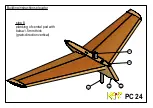

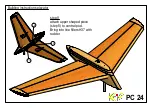

Building instructions elevator