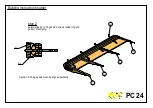

step 4

lower planking with light Balsa 1.5mm thick (H15)

elevator tips of 3 parts H29 and H30

servocovers H31 and horns H38

PC 24

H30

H29

H29

H15

H31

H31

H15

H29

H30

separate movable part

cut through between H24 and H25

hinged on the upper surface

(have a look on the fotos in the

building section of CD)

H38

H38

Building instructions elevator