Page 32

DOC0945 (22 August 2022 15:28)

www.keit.co.uk

Back to Table of Contents

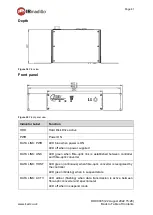

Table 9 - Specifications and safety limits

Parameter

Port flange

Pressure

Limited by the ASME B16.5-2020 Pipe Flanges and

Flanged Fittings standard. Pressure derated with

temperature

Analyte Temperature

Refer to IRmadillo product label

Probe Body Material

Hastelloy C276

Port flange Material

Hastelloy C276

Gasket Material

Customer supplied. Material must be to specification

of standard ANSI B16.21 or EN equivalent

Port Size

Nominal pipe size: 2 inches

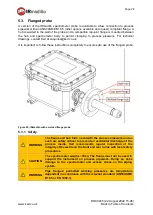

5.5.2. Installation

The sealing face on the probe requires a gasket to mate against the flange on the process

pipework. The gasket material must be chosen to be compatible with the pressure and

temperature range of the process media and must be chemically compatible.

WARNING

Choice of gasket material must be appropriate for the chemistry

and process being used.

The probe body and hub are manufactured from Hastelloy, which is resistant to many

aggressive chemicals.

However, you are advised to check with Keit before installing on

a new process.

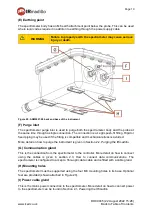

Before beginning installation, ensure that the gasket is in good condition and that the sealing

faces are not scratched or dented.

If the IRmadillo is not going to be installed into the pipe immediately, the blanking plug can be

positioned with the groove aligning with the rear of the port tube and held in place using the

sanitary tri clamp.

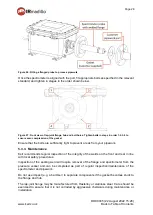

Support the spectrometer on a suitable mounting frame that aligns the probe with the flange

port to which it will be fitted. The probe is inserted through the port tube; it must have a O-ring

positioned in front of the clamping groove to seal.

Avoid applying stress to the probe or flange by ensuring that the sealing face of the hub sits

flush against the gasket and sealing face of the mating flange before fitting any mounting bolts

to the flange.

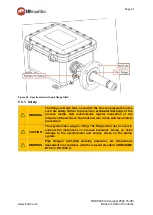

5.5.3. Maintenance

Keit recommends regular inspection of the integrity of the welds on the front and rear in line

with local safety procedures.

Inspection of the sealing weld will require removal of the flange and spectrometer from the

pressure vessel and can be completed as part of regular inspection/maintenance of the

spectrometer and pipework.