Verifying AC current

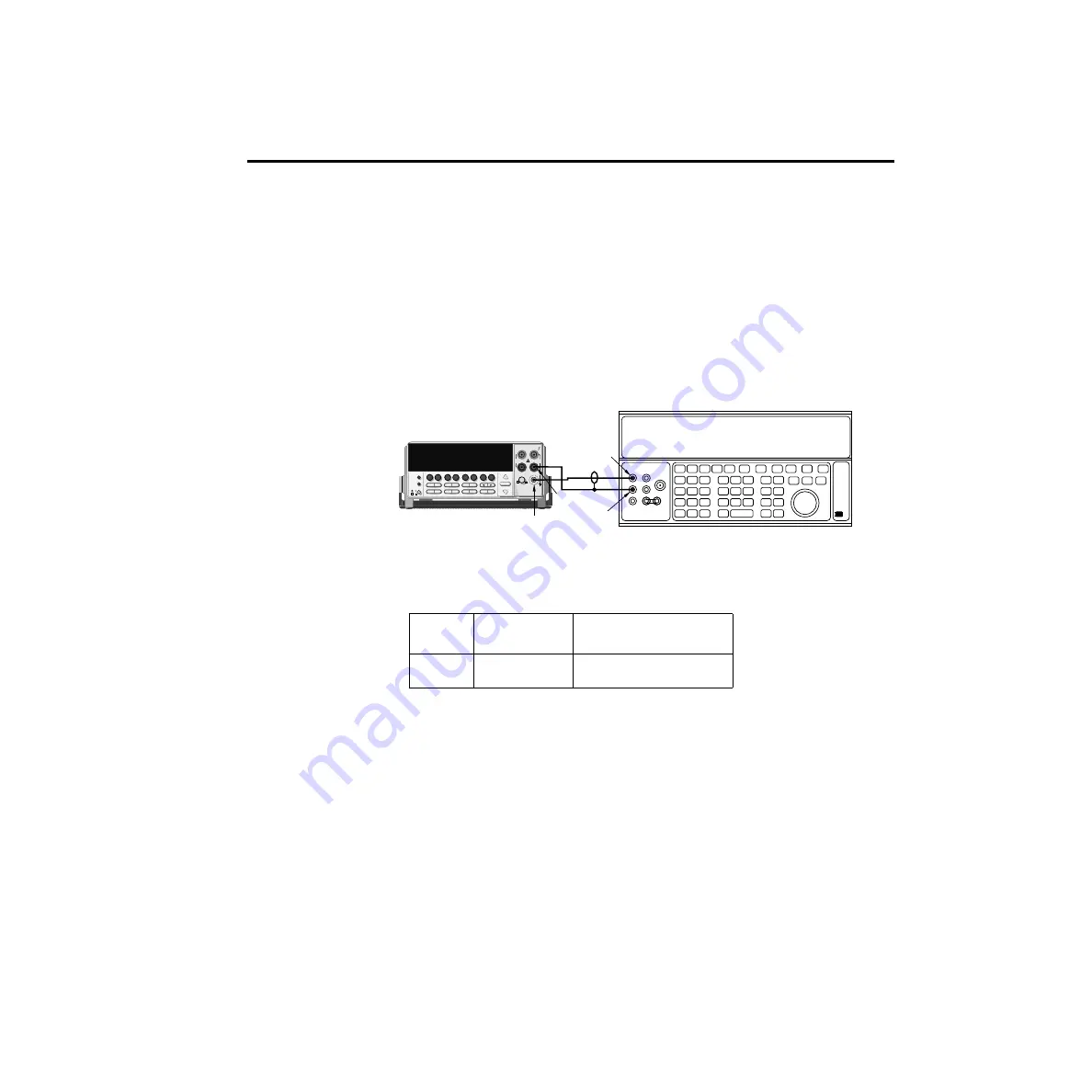

Check AC current accuracy by applying accurate AC current at specific frequencies from the

AC current calibrator to the Model 2010 input and verifying that the displayed readings fall

within specified limits. Follow these steps to verify AC current:

1.

Connect the Model 2010 AMPS and INPUT LO jacks to the calibrator as shown in

2.

Select the AC current function by pressing the ACI key.

3.

Set the Model 2010 for the 1A range.

4.

Source 1A and 2.2A, 1kHz full-scale AC currents as summarized in

, and verify

that the readings are within stated limits.

Table 1-5

ACI limits

ACI

range

Applied DC

current

Reading limits

(1 year, 18°C–28°C) 1kHz

1A

3A

1.000000A

2.20000A

0.99860 to 1.00140A

2.1949 to 2.2051A

2000 MULTIMETER

!

R

5700A Calibrator (Output AC Current)

Output HI

Input

LO Output

LO

Model 2010

Amps

Figure 1-4

Connections for AC

current verification

Performance Verification

1-9

Summary of Contents for 2010

Page 14: ...1 Performance Verification 1 Performance Verification...

Page 28: ...2 Calibration 2 Calibration...

Page 53: ...3 Routine Maintenance 3 Routine Maintenance...

Page 56: ...4 Troubleshooting 4 Troubleshoot ing...

Page 74: ...5 Disassembly 5 Disassembly...

Page 83: ...CONFIDENTIAL PROPRIETARY...

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ...6 Replaceable Parts 6 Replaceable Parts...

Page 98: ...CONFIDENTIAL PROPRIETARY...

Page 99: ...CONFIDENTIAL PROPRIETARY...

Page 100: ......

Page 101: ...A Specifications A Specifications...

Page 107: ...B Calibration CommandReference B Calibration CommandRef erence...