Electrical

All electrical work associated with the F60

must be carried out by qualified electrical

personnel and all electrical work must

conform to AS/NZ standards and to local

wiring rules. For mains voltage applications

we recommend the supply to the F60 be

isolated by an RCD that has a maximum trip

current of 30mA.

WARNING

Introduction

The F60 is designed to directly control single-phase pump motors to 2.4kW. No

interposing contactor is required for such applications. If a supply neutral is

available the controller can also be used to control 3 phase pump motors via an

appropriate interposing contactor.

The F60 requires a 220V to 240V AC 50Hz supply when operated from the mains.

It can also be operated from an 18 to 24V AC or DC supply by utilising the low

voltage active terminal LV and common neutral terminal N (see the included wiring

diagrams). When operated from a low voltage DC supply the terminals LV and

neutral N are not polarity sensitive. The controller requires a stable supply voltage

in order to operate correctly. Pay particular attention to cable sizes, and ensure

cables are adequate for the specific pump motor load.

This is particularly important where long cable runs are to be used in the installation.

If the voltage drop associated with the starting of the pump motor is excessive the

F60 will automatically reset and this may cause the pump to jog. Jogging can

snap the main spindle of a pump very easily, so please take all precautions to

ensure the voltage supply to the F60 is stable and that the current carrying

capacity of the cable is adequate for the job.

15

Summary of Contents for F60

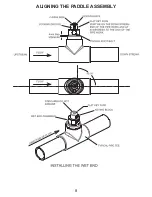

Page 11: ...ALIGNING THE PADDLE ASSEMBLY 8...