KCO-NO2 User’s Manual

90-0201-01

Kele • 3300 Brother Blvd. • Memphis, TN 38133

Page: 10

WWW.KELE.COM

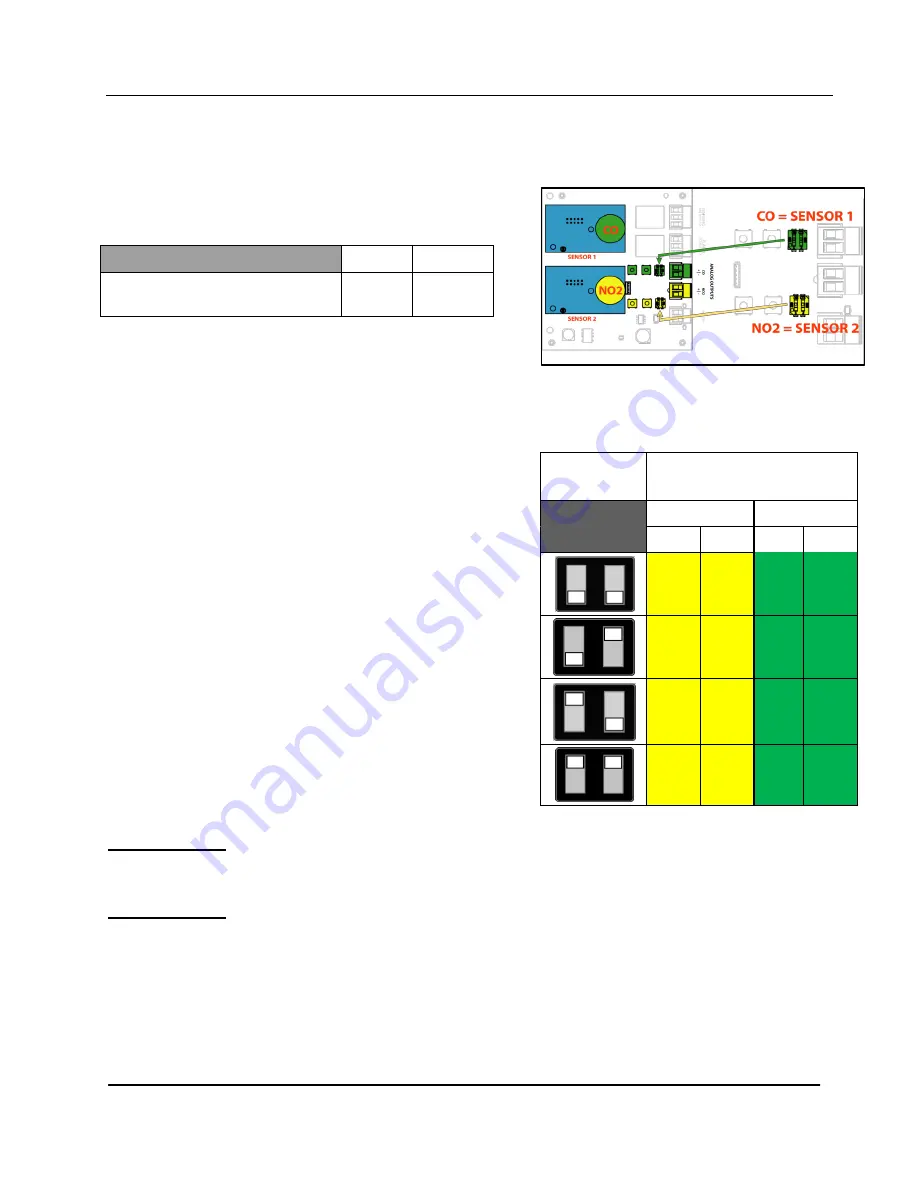

Dipswitch

Setting

Threshold Set Points

[ppm]

NO

2

CO

Warn

Alarm

Warn

Alarm

0.7

2.0

15

30

1.0

3.0

25

40

2.0

2.0

30

45

2.5

4.5

35

45

FIGURE 8:

Setting Warn & Alarm Set points

Figure 7

: Dip Switch Locations. CO specific

adjustments and connections are highlighted

in yellow while NO

2

specific adjustments

and connections are in green.

4.3 Setting Warning and Alarm Threshold

The controller has a warning and alarm threshold for each gas. These threshold values can be

adjusted for each sensor via dip switches on the controller’s main board (shown in Figure 7) Refer

to details on setting the thresholds for each sensor in

Figure 8.

NO

2

CO

Federal OSHA Personal

Exposure Limit (PEL).

5 ppm

50 ppm

TABLE 5: Federal OHSA exposure limits

(29 CFR 1910.1051 TABLE Z-1)

4.4 Warning and Alarm Conditions

The controller has two LEDs on the front panel (one for

each sensor). These LEDs change color to indicate the

controller’s current operational status. Table 3 shows

the behavior of the front panel LEDs during normal

operation.

Two dry-contact SPDT relays are provided on the

controller, these relays activate during warning and

alarm conditions. Refer to

Section 3.3

for location and

wiring information.

Readings for the two sensors are independently reported

on the controller’s two 4 – 20mA powered current loop

outputs during normal operation. Theses outputs are

electrically isolated from the operating power

connection.

Table 2 lists the operational conditions that force the

analog outputs to their limits regardless of ambient gas

concentrations.

4.5 Abnormal operation

Both of these conditions will put the KCO-NO2 into

‘Sensor Error’ mode (see Table 2).

Sensor Expired

Happens only after a span calibration if the sensitivity of the sensor has decreased by more

than the manufacturers specification (usually 20%)

Sensor Failure:

Can happen at any time. Caused when the sensor supervision circuitry detects a catastrophic

loss of a senor’s sensitivity, usually caused by a depletion of the senor’s electrolyte through a

leak or evaporation.