KCO-NO2 User’s Manual

90-0201-01

Kele • 3300 Brother Blvd. • Memphis, TN 38133

Page: 8

WWW.KELE.COM

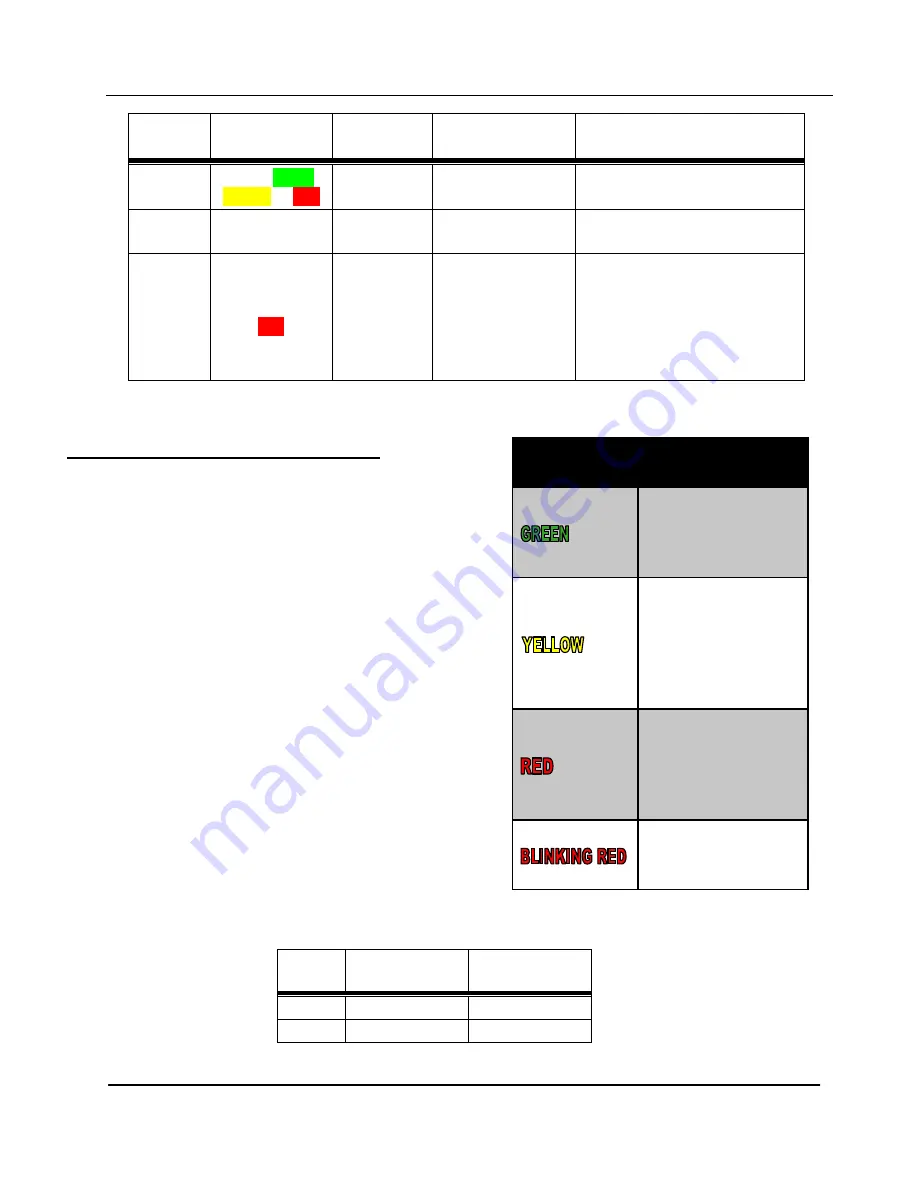

Status LED

Color

Operational Status

Description

Concentration is

below the ventilation

threshold. No

outputs are active.

Concentration is

above the ventilation

threshold and below

the alarm threshold.

Ventilation relay is

active.

Concentration is

above the alarm

threshold. Both

ventilation and alarm

relays are active.

Sensor module in

need of service (refer

to Section 6).

Table 3

: Front panel status LED

Indications.

Sensor

Concentration

at 4 mA

Concentration

at 20 mA

CO

0 ppm

200 ppm

NO

2

0 ppm

10 ppm

Table 4

:

Sensor Analog Output Scaling

4 Operational Description

4.1 Normal operation

The KCO-NO2 is a ventilation and alarm

controller that senses the presence of gasoline or

diesel engine exhaust fumes and operates a

Warning contact closure to trigger exhaust fans or

a minor alarm annunciator when elevated levels

of carbon monoxide (generated by gasoline

engines and abbreviated CO) or nitrogen dioxide

(from diesel engine exhaust and abbreviated

NO

2

) are detected. If the concentration of either

gas exceeds its programmed alarm value, a

second set of alarm contacts is operated to trigger

an alarm.

The controller has two independent sensor

modules; one for sensing carbon monoxide (CO),

the other senses nitrogen dioxide (NO

2

). The

sensor modules are field replaceable: each sensor

module can be replaced with minimal effort when

it reaches end-of-life (EOL) while leaving the

main control mounted and wired (refer to

Section

7.1

).

Mode

Front Cover

LED

Analog

Output

Relays Actuated

Comment

Normal

Steady Green,

Yellow or Red

4 – 20 mA

Depends on

concentration

During normal operation

Standby

Various

4 mA

NONE

During start-up interval or any

time during calibration

Sensor

Error

Slow Blinking

Red

20 mA

Warning/

Ventilation

After calibration of expired

sensor or detection of sensor

failure.

Sensor is no longer operational

and must be replaced.

TABLE 2

:

Operational State Summary