19

Chainsaw bar

Turn the bar periodically to prevent wear.

The bars edge should always be square. Check that the bar edge is

not worn. Place a ruler on the chain outside a link. If there is a gap

between them, the edge is normal. Otherwise, the bar edge is worn.

A worn guide bar may need to be adjusted or replaced.

(1) Ruler

(2) Gap

(3) No glitches

(4) Chain tilts

Chainsaw

Cutting links must be kept sharp, not only for the machine to cut

efficiently, but also for safety reasons.

Your cutting links must be sharpened when:

•

The sawdust becomes powder like

•

When additional force needed to saw.

•

When the cutting the track is not straight.

•

When the vibrations increase.

Cutting links:

Wear protection gloves!

Before grinding:

•

Make sure the chainsaw bar is held securely

•

Make sure that the machine is turned off, unplug!

•

Use a round file of proper size for your chain

•

Place your file on the cutter link and push the file straight for-

ward. Keep the file in position as illustrated in Figure 1

•

After each cutting link has been grinded, check the groove

depth and grind it to a good level, as shown in the Figure 2.

Make sure to round off the front edge to reduce the risk of kick-

back or the chain breaking off

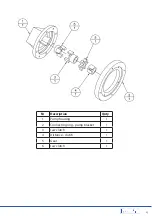

(1) Suitable control of the groove depth.

(2) Round of the lug

(3) Normal groove depth

Make sure that each link has the same length and edge angles as

shown (Figure 3)

(4) Cutting length

(5) Filling Angle

(6) The side angle of the plate

(7) Top plate cutting angle

Never grind the chain if the tooths thickness is only 3 mm left

(1)

(2)

(3)

(4)

FIG. 3

60°

80°

30°

FIGURE 1

30°

FIGURE 2

0,65mm