25

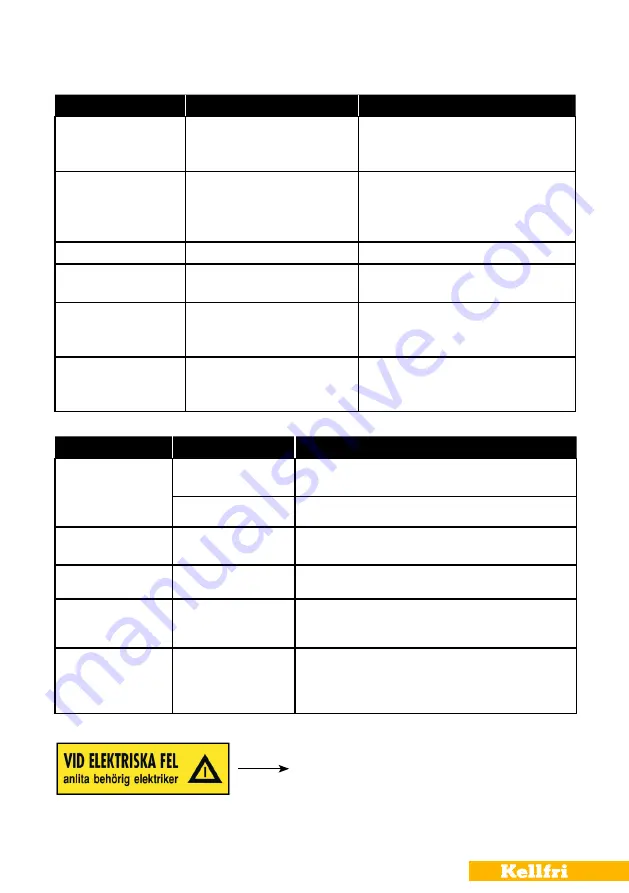

SERVICE

INTERVAL

MEASURE

Blades

Before each use

Replace all defective blades. Sharp blades give better results.

When replacing blades, tighten bolts fully.

While operating

Listen out for noises

Infeed rollers

After 20 hours of

operation

Lubrication

Hydraulics

Before each use

Search for leaks; check all connections and hoses

Safety fixtures

Before each use

Check safety devices.

E.g. safety valves, guards, etc.

Bearing

Regularly

50 hours of operation

Lubricate bearings with grease regularly. If the machine is used a

lot, all bearings should be greased every week. Otherwise, every

50 hours of operation or once per year

TROUBLESHOOTING

CAUSE

MEASURE

Poor chip quality, wood

unevenly chipped

- Blunt blades.

- Cutting distance between blades is

uneven or too wide.

- Check blades.

- Adjust and grind if required.

The chipper does not pull in

the trees/branches

- The blades are facing the wrong way.

- Blunt blades/Wrong angle on ground

blades

- The feeder does not feed in the trees

- Check blades.

- Turn around, adjust and grind if required

- Check that the feeder is correctly connected and

is working properly.

Blockage in discharge chute - Operation speed too low.

- Increase speed to 540/1000 rpm.

Major vibrations

- Cutting speed and infeed speed are

not in synch.

- Adjust infeed speed.

Infeed rollers do not rotate

or are too slow

- No pressure in the hydraulic system.

- Low oil level in the hydraulic system.

- Check the oil level and for any leaks in the

hydraulic system.

- Fill with hydraulic oil.

Does not pull in all timber

toward the chipper, rattles

- There is a piece of wood between the

infeed rollers and the chipping disc.

- Feed in a new log to press the remaining wood

into the chipper or reverse the feed to remove

the piece of wood.

TROUBLESHOOTING

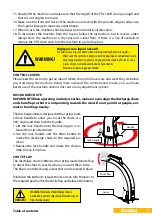

NOTE Make sure the machine is turned off and disconnected before performing any intervention.

WARNING! In the event of an electrical fault,

a qualified electrician must be consulted.

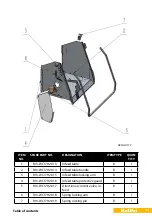

Summary of Contents for 13-WC17H2

Page 34: ...34 Table of contents Version 1 1...

Page 36: ...36 Table of contents Version 1 1...