7

USE

Only people who understand the safety information and instructions in this manual may op-

erate the equipment. Be alert and careful when working with the machine and only use the

equipment or product in the manner described in this manual.

When working with equipment that has moving parts, there is always the risk for injury. Al-

ways work alone with the equipments that are defined as single porpose equipments.

Never overload the machine. Respect the equipment’s danger zone.

Make sure you know the distribution capacity of your machine and the material to be used.

Test drive on the field to be sure that the spread will be right aligned. To much spread can dam-

age the crop and ungenerous distribution may not produce the desired results.

•

Reduce speed when working on slopes and uneven terrain.

•

Make sure that no foreign objects is in the fertilizer/salt or sand to be spread.

•

Follow the guidelines that the ATV manufacturer provides regarding towing / pulling of

equipment / utensils.

•

Do not fill the spreader container when you are transporting the equipment on longer

distance. Because the contents can get packed and affects and damaged the spreader

plate and affect the ability to spread.

•

Be extremely careful if you spread herbicides when there is a risk if uncontrolled spread-

ing happens because of strong wind can lead to damaging the vegetation outside the

area. Always follow the instructions for the chemicals you use.

•

If there would be a stop in the spreader plate inside the container: stop the machine,

make sure all moving parts have stopped, and open the feeder cover completely. By put-

ing a stick in the feeder you should be able to remove the object.

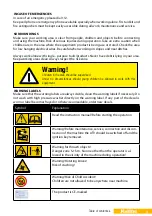

WARNING!

Risk of

crushing!

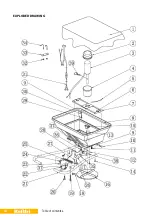

SETTING YOUR SPREADER

•

The opening in the bottom of the spreader containers is adjusted with the control lever.

•

The size of the opening depends on the calibration scale. Put the lever in the desired

position.

•

For proper distribution calibrate your towing vehicle to run at the desired speed.

•

Close the feeder cover and fill the container of tha material to be spread. Run a test drive

and make sure you gets the desired results. Make adjustments if necessary.

The spreading amount is determined with regards to:

•

The kind of fertilizer that will be spread

•

Working width [m]

•

Working speed [km / h]

•

The desired spread rate [kg / ha].

Various factors such as wind, fertilizer humidity, etc. can affect the ability to spread.