3

INTRODUCTION

Thank you for choosing a product from Kellfri AB. Compliance with the safety instructions, op-

erating manual and sound common sense will guarantee many years of enjoyment using the

product. Kellfri’s equipment and products are aimed at self-employed farmers,

horse enthusiasts and other country dwellers with stringent performance demands.

PRODUCT INFORMATION

With its low weight and working width of 1.45 m, the WKS145 verge flail mower is ideal for

smaller tractors of 25-45 hp. By means of the side shift adjustment, the verge flail mower can

be adjusted for work either behind the tractor or variably at the side.

You can easily cut ditch edges, median strips on roads and other places that are difficult to

reach.

The verge flail mower has a tiltable cutting head and can be angled 90° upwards and 50°

downwards laterally, which makes it very flexible. This makes the machine particularly suit-

able for cutting and topping ditch edges, but it works equally well on level areas and hedges.

The mower has a fine-toothed welded counter bar in the chassis to break up the material more

effectively.

The front of the verge flail mower is fitted with steel plates that adapt to the substrate and

protect both the tractor and the surroundings from stone chipping and grass spray.

The support roller has a scraping iron to keep the roller free from cut material.

The verge flail mower is fitted as standard with hammer flails.

The hydraulic side shift adjustment enables you to shift the machine to the left or right. The

side shift adjustment means that you can cut at the side of your tractor and thereby reach

ditch edges and the median strip of roads, which would otherwise be difficult to reach.

The hydraulic side shift adjustment enables you to drive with just one pair of wheels in the

uncut area and cut closer to ditches, fences, etc. The maximum side shift adjustment of the

machine is 204 cm to the right from the mid-point of the tractor.

The machine's cutting head can be angled 90° upwards and 50° downwards. High level of safe-

ty with collision protection that angles the machine upwards if you hit a stump, for example.

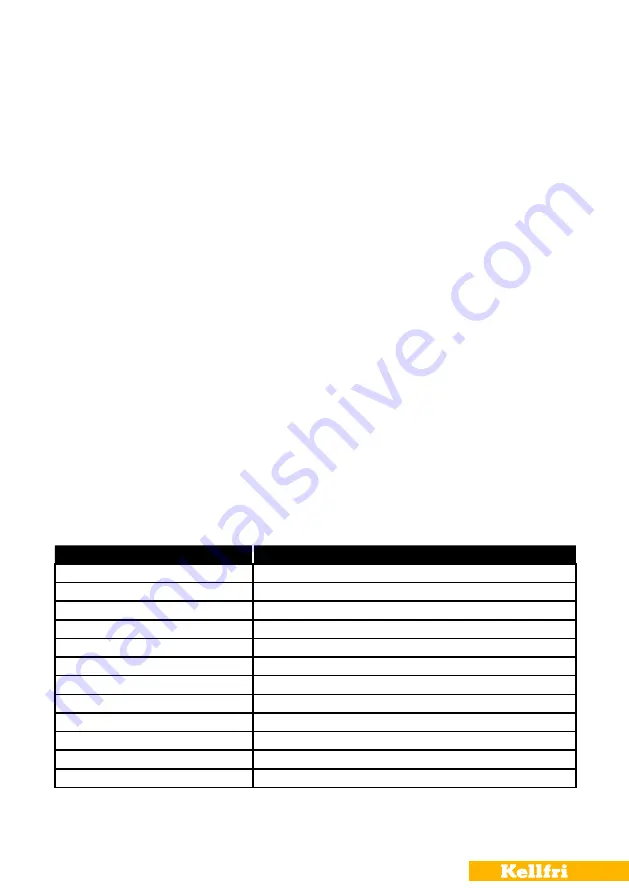

TECHNICAL DATA

35-WKS145

Length x width x height

1560 x 690 x 530 mm

Working width

1450 mm

Hydraulics

Requires 2 double-acting cylinders

PTO shaft

Standard

Side shift adjustment, hydraulic

Yes

Power requirement

25-45 hp

RPM

540 rpm

Operating speed

6-12 km/h

3-point linkage

Cat. 1

Weight

307 kg

Number of flails (hammer)

24

Gearbox, transmission oil

1.2 L

Summary of Contents for 35-WKS145

Page 18: ...18 GREASE POINTS...

Page 22: ...22 Version 1 1...

Page 24: ...24 Version 1 1...

Page 26: ...26 Version 1 1...

Page 29: ...29...