5

run and the intake filters should be installed at the end of the pipes with a hood to

protect them from the elements.

If the compressor has to be located where the motor will be exposed to

appreciable quantities of water, oil, dirt, acid, or alkaline fumes the motor must be

of special construction to avoid rapid deterioration.

Bolt the unit securely and evenly to a level base, using shims if required.

Allow sufficient space around compressor so that it is accessible from all sides for

maintenance. Mount the unit with pulley side toward the wall, but at least six (6)

inches from it.

Starting:

A.

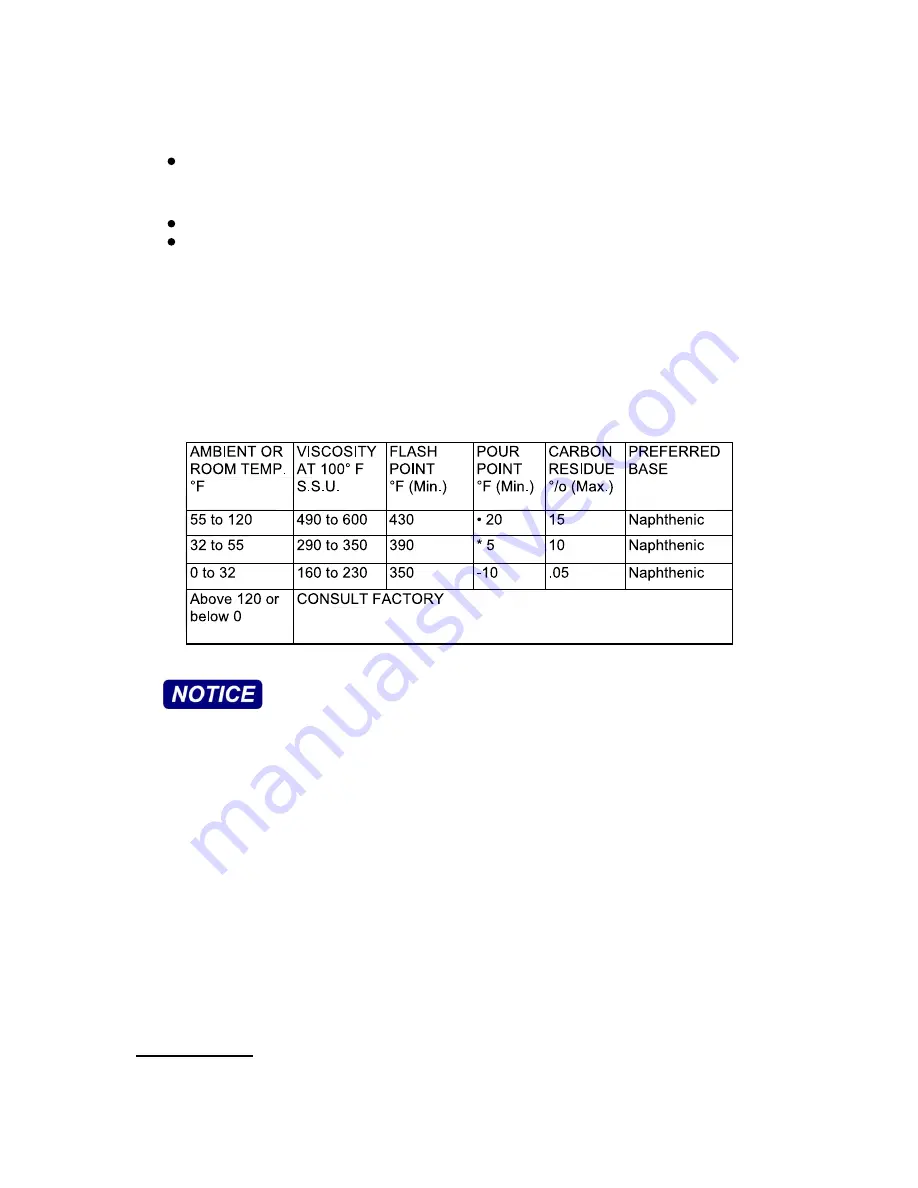

If compressor is shipped without oil in the crankcase, before starting, fill

crankcase to the high level mark on the sight glass with Kellogg-American

oil

meeting the following specifications:

For operation in damp or humid conditions, addition of rust inhibitor is

recommended.

B.

Turn compressor over a few revolutions by hand to make sure all parts are free

and in running condition.

C.

Check the tension of the belts.

D.

Remove tools, rags, and other objects from the vicinity of the compressor.

E.

Never put hands or tools on the belts of idle units unless the main power is

disconnected and locked.

F.

Note directions of arrow on flywheel and be sure the direction of rotation is

correct when machine is started. Correct direction is counter-clockwise when

facing the flywheel. Air should be drawn through the intercooler onto the

cylinders for maximum cooling.

Maintenance