RCA2610 Series Installation/Operation Guide

Page 7 of 14

Rev

D

KELLY MANUFACTURING COMPANY

KMC

KMC

Publication No.1401-3

SECTION 2, INSTALLATION

2.1 GENERAL INFORMATION

The conditions and test required for the TSO approval of this article are minimum performance standards. It is the responsibility of

those installing this article either on or within a specific type or class of aircraft to determine that the aircraft installation conditions

are within the TSO standards. TSO articles must have a separate approval for installation in an aircraft. The article may be installed

only if performed under 14CFR Part 43 or the applicable airworthiness requirements.

For certain classes of Part 23 aircraft level C of DO-178B certification may not be sufficient - check with your local regulatory

authority prior to installation.

2.2 HANDLING

Although the RCA2610 Series instruments are totally electronic, improper handling can cause damage. Please observe the

following precautions while handling.

1. Do not drop, jar or shake instrument. Store instrument in shipping container until installation.

2. Instruments should be transported in the original shipping container when moved to and from aircraft. If container is not

available, carefully carry by hand in upright position.

3. Avoid touching the screen. This is the most vulnerable part of the instrument. Improper handling and cleaning can cause

permanent scratching of the screen surface (See

Instrument Care

on Page 9).

4. To prevent further damage, a malfunctioning instrument should be handled as carefully as a new instrument. Most mal-

functioning instruments can be repaired and returned to service. Contact Kelly Manufacturing Company for repair and

warranty information.

2.3 PRE-INSTALLATION INSPECTION

1.

When the instrument is first received, inspect container for any shipping damage.

2. Carefully remove the instrument from shipping container and retain container for later storage or shipping.

3.

Inspect the instrument for any signs of damage. Contact your Shipper to file any claim due to shipping damage.

4. Check labeling on the instrument to assure that the instrument panel tilt angle is correct for your aircraft.

2.4 INSTALLATION

Install the instrument on the aircraft by using the aircraft manufacturer’s recommendations and by the following steps:

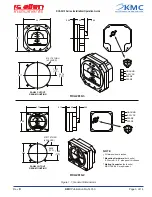

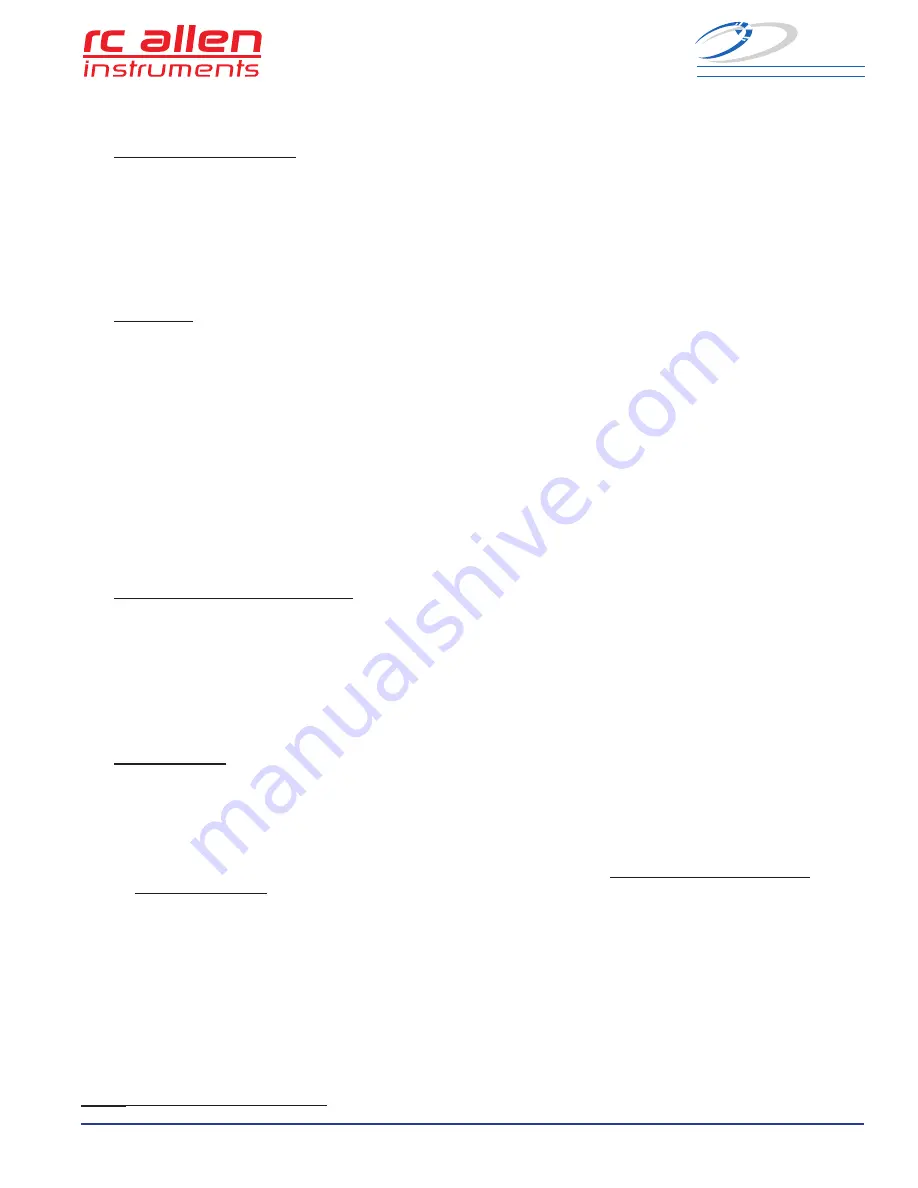

1. The RCA2610 Series Horizon uses standard panel cutouts. Refer to Figures 1.1 and 1.2 “General Dimensions” for

instrument and cutout dimensions.

2. Instrument Pinout is: A = GND, B = PWR, C = SPARE, D = SPARE.

CAUTION:

Do not apply power to Spare pins

as damage may occur. See table 1.1 “Leading Particulars” for additional electrical information.

3. Attach aircraft electrical connector to the instrument and insert into the instrument panel cutout (See Figures 1.1

and 1.2).

4. Secure instrument with supplied screws. Use 6-32 UNC-2b screws or equivalent. Screw length should not ex-

ceed .5 inches plus bezel and panel thickness. Do not tighten.

5. With the aircraft on level surface, apply power to the instrument and allow it to warm up for 3 minutes.

6. Adjust roll position of the instrument by visually aligning the roll pointers. The Horizon Line should be level and

unbroken. Tighten screws.

Do Not

modify the instrument in any way

. Any modifications will void the warranty and revoke the FAA certifications.