14

SERVICE AND MAINTENANCE

1) Tip the bowl into the downward position. Remove the shaft

endcap and carefully release the split pin.

2) Drop the bowl out of the bearing assembly with the shaft still

attached.

3) Re-position packing washers. To increase gear engagement

reduce the amount of washers at the top of the shaft and move

to the end of the shaft under the split pin.

4) Insert the shaft of the bowl back into the bearing arm

assembly.

5) Insert more packing washers onto the shaft as required. There

should be no vertical movement or gap between the packing

washers and split pin.

6) Insert split pin and using pliers bend split pin ends to secure.

HOW TO APPLY GREASE TO THE TIPPING ARM

CAUTION!

Do not mix grease types. Chemical incompatibility

in lubricants can destroy bearings very quickly. It is advised to

remove all old grease on the first service change to avoid risk.

NOTE:

The grease nipple is a combination ball valve and check

valve. The grease gun depresses the ball valve allowing grease

to pass. When the gun is removed the valve should close, sealing

in the grease. If the valve doesn’t close and grease leaks out,

there may be particulate matter obstructing its proper operation.

You should replace the nipple.

• Always clean off the grease nipple with a rag before

attaching the grease gun coupler. This will prevent pumping

contamination into the bearing assembly.

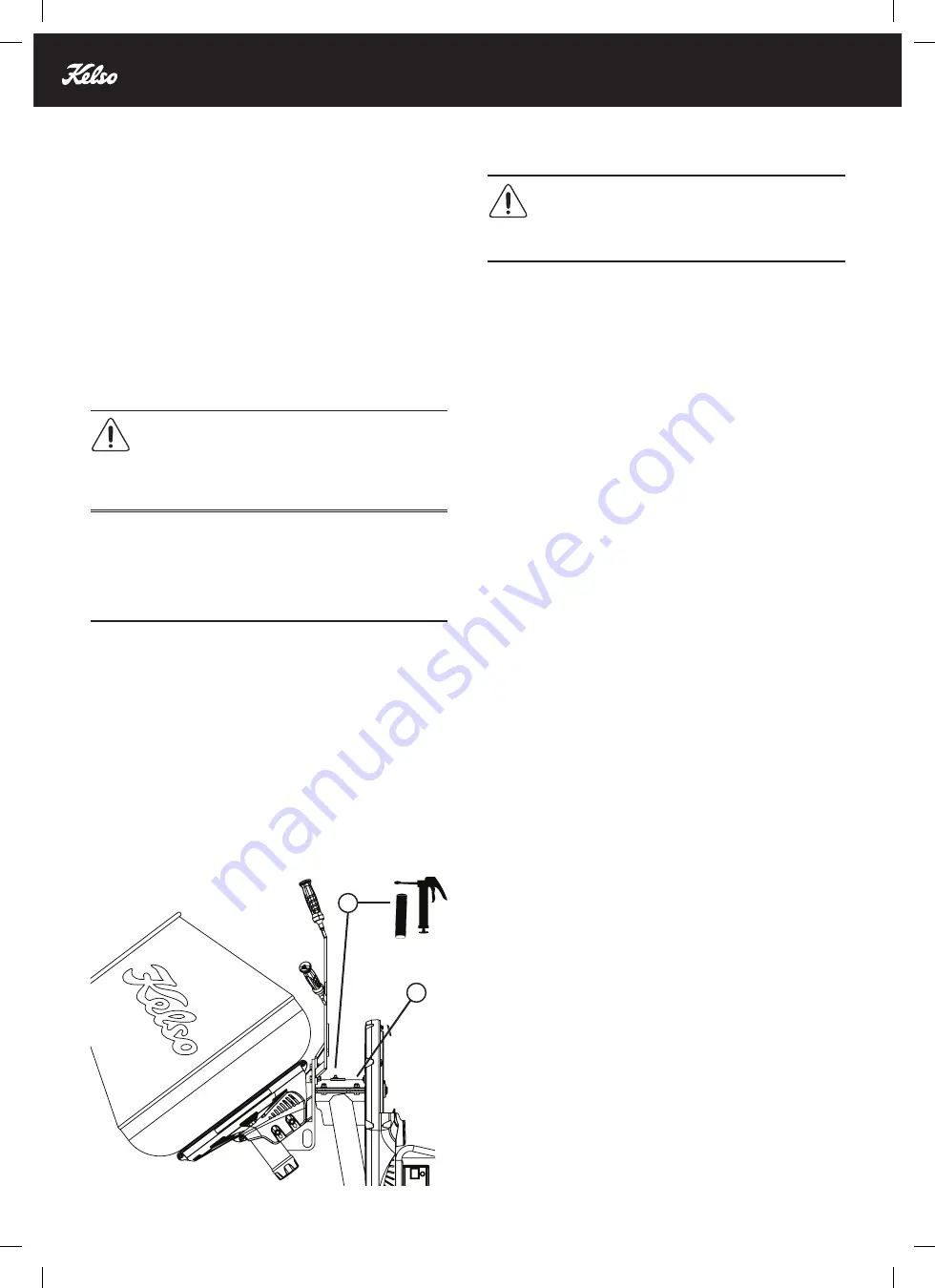

(Figure 15 - A)

• During first service, remove the top mount plate and clean

away all old grease.

(Figure 15 - B)

• After cleaning, reattach the top mount plate and pump in new

grease with a grease gun.

• Periodically tip the drum using the tipping handles to help

disperse the grease around the shaft.

• Pump enough grease that you hear escaping pressure and

see just a little bit of grease movement squeeze out of the

assembly.

• DO NOT apply grease to the pinion gear or teeth ring. Grease

can attract foreign contaminants leading to premature wear.

CLEANING THE POWER TOOL

CAUTION!

Do not point the water directly at any electrical

components.

• Clean the machine during and after every use. Remove any

dust, residual mixing material and any other dirt.

• Cleaning is best done with a stiff brush. Wear safety glasses

whilst brushing away dust and dirt.

• Use running water from a hose or a high-pressure washer to

clean the product.

• After every mix it is advisable to clear any build-up of cement

from the mixing paddles inside the mixing bowl. If left to

dry the cement can be extremely difficult to remove without

damage to the bowl.

TIP:

Run the Power Tool with a mixture of screenings and

water to remove any dried or clogged cement from inside the

mixing bowl.

• After every mix it is advisable to clear any build-up of cement

from the gears. If left to dry the cement can lead to premature

wear.

• After the last mix wash and clean ALL cement build up from

both inside and outside the mixing bowl and any other exposed

parts before the cement fully sets.

• Avoid hitting the bowl with any objects.

• After cleaning the mixing bowl, the power tool should be stored

with the mixing bowl in the downwards position to ensure all

water is drained.

• Remove grease and oil from the handle.

• The ventilation holes on the motor cover must not be blocked.

• NEVER use solvent-based cleaning agents, these may damage

the painted surfaces or the plastic parts. If you must use these

cleaning agents, test the effect of these agents on a small,

concealed area

FIGURE 15

H

E

A

V

Y

D

U

T

Y

G

R

E

A

S

E

A

B

Summary of Contents for KCM65

Page 2: ......