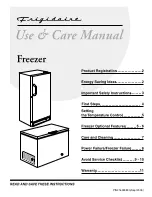

REPLACING THE CHAMBER GUARD

To install the New Vinyl Guards, Proceed as Follows:

1. Clear off the old mastic from around the top chamber

guard retainer.

2. Mastic is to be used between the stainless steel top

and the top chamber guard retainer. Hold the

tapered edge of the spout at an angle, then press

on tube and force mastic out. Pull along the retain-

er at an even pace.

3. Hook the four corners of the chamber guard in place

and work the top edge along the top retainers hooking

the top edge in place. (B). Then stretch the chamber

guard downward, and hook in place over the bottom

retainer (C). If there is any excess mastic from around

top, Hexane, light naptha, will remove the mastic.

LIDS

The cabinet lids of the Flip-Flop design are made in two

widths: single width and double width. The double width

lids are for the double row cabinets and cover the square

area so the lids may be placed to lift from side to side of

from end to end as desired. Stainless steel lid assem-

blies are made in two widths.

To replace the hinges, proceed as follows:

1. Remove the lid from the cabinet.

2. Remove the screws securing the hinge plate to the lid.

3. Remove the defective hinge.

4. Align the new gasket and hinge plate in insert screws.

REPLACING STAINLESS STEEL TOP CAP

Should it become necessary to remove or replace the

top capping, the rivets can easily be removed by drilling

out with a small electric drill using a No. 30 drill to insure

not increasing the size of the hole in either the cap or the

wrapper. In reassembling, install 1/8" aluminum pop

rivets, Number 576860, in the holes throughout the stain-

less steel cap and the cabinet wrapper.

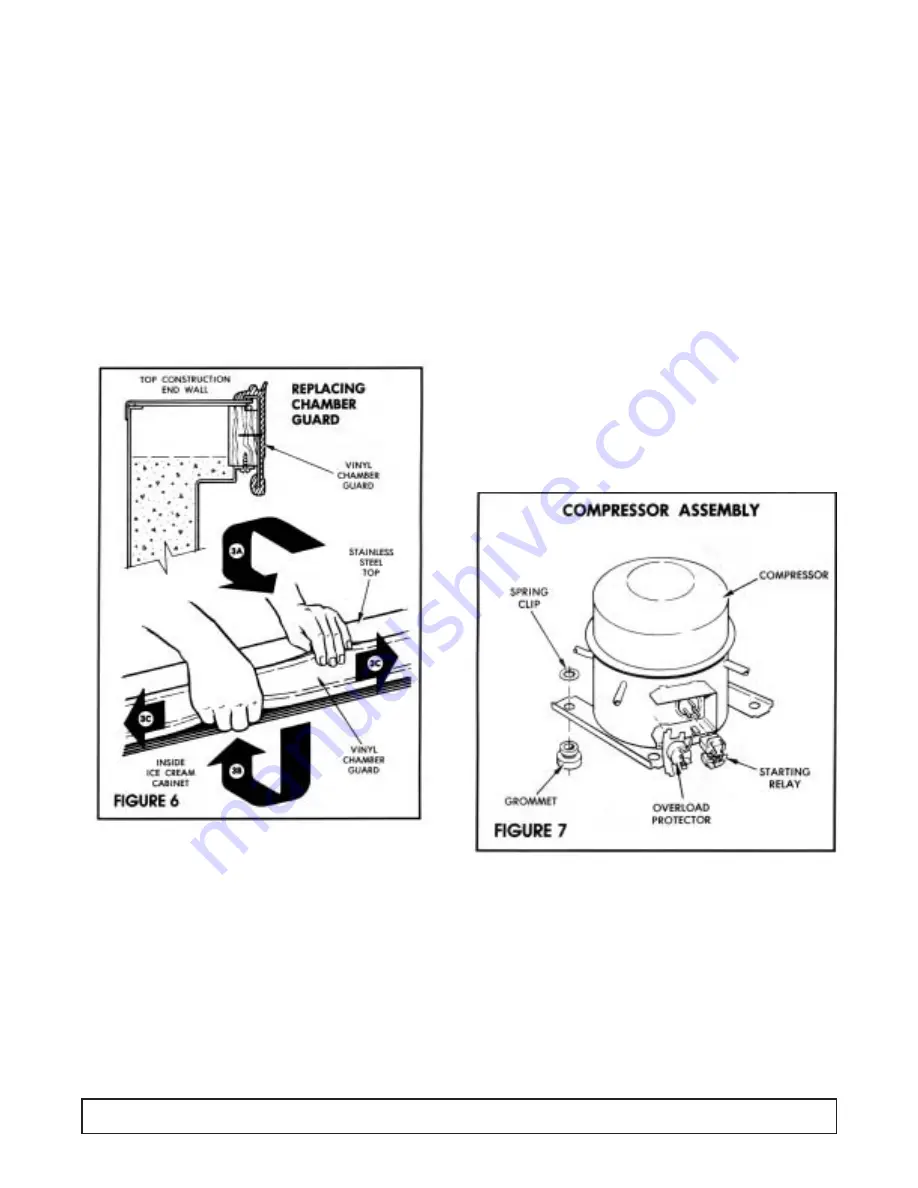

REFRIGERATING SYSTEMS

All compressors have fusite mounted terminals and a

plug-on starting relay. The overload protector plugs on

the common fusite terminal.

The compressor and motor are built as one unit and

spring mounted inside a steel shell. Welded construction

makes the unit hermetically sealed. The compressor

embodies a reciprocating type pump, directly

connected to the motor.

An oil pump supplies oil to every moving part and liter-

ally floods every bearing surface with oil to minimize

friction and insure quiet operation. The compressor

dome is four-point base mounted.

CONDENSER

The condenser tubing is held to the inside of the cabinet

wrapper or shell along the front, the back, by saddle

clamps which are spot welded to the outer shell.

Efficient heat transfer is obtained from the tube to the

entire shell which is the condenser surface. By the nat-

ural convection of the room air due to the absorption of

the heat from the wrapper, an efficient cooling action is

obtained and sufficient heat is removed from the hot

compressor refrigerant vapor to result in the liquidation

of the refrigerant. During the initial pull down of a hot

GENERAL OPERATIONS

11